A disc crusher

A crusher and disc-type technology, applied in cutting machinery, slitting machinery, earth drilling and mining, etc., can solve the problems of hard rock crushing not being widely used, tool wear, and tool affecting mining work efficiency, etc., to achieve The effect of speeding up crushing and mining, easy to replace and easy to disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in further detail below in conjunction with accompanying drawing:

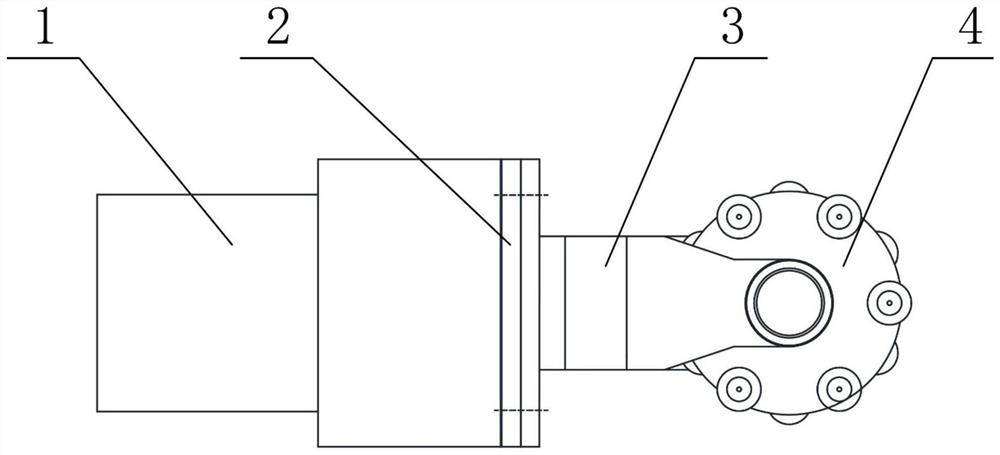

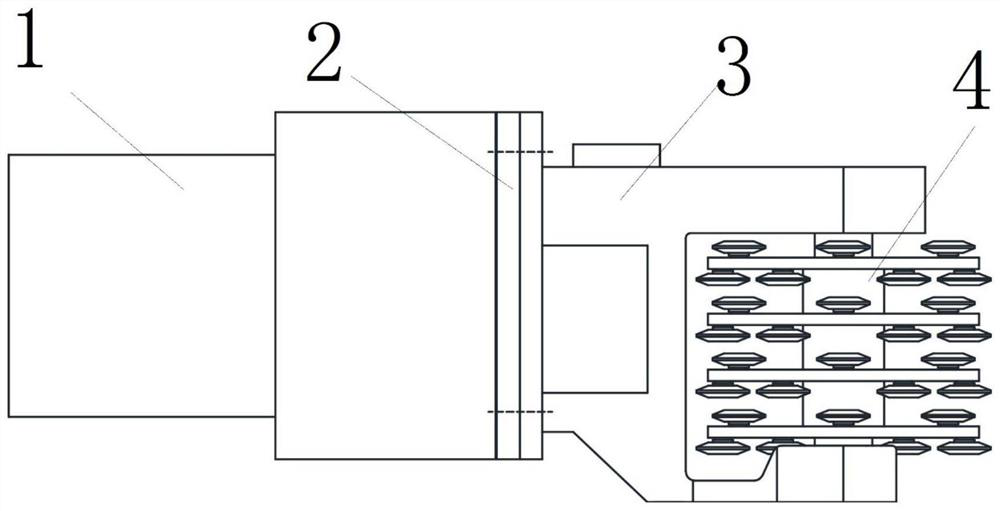

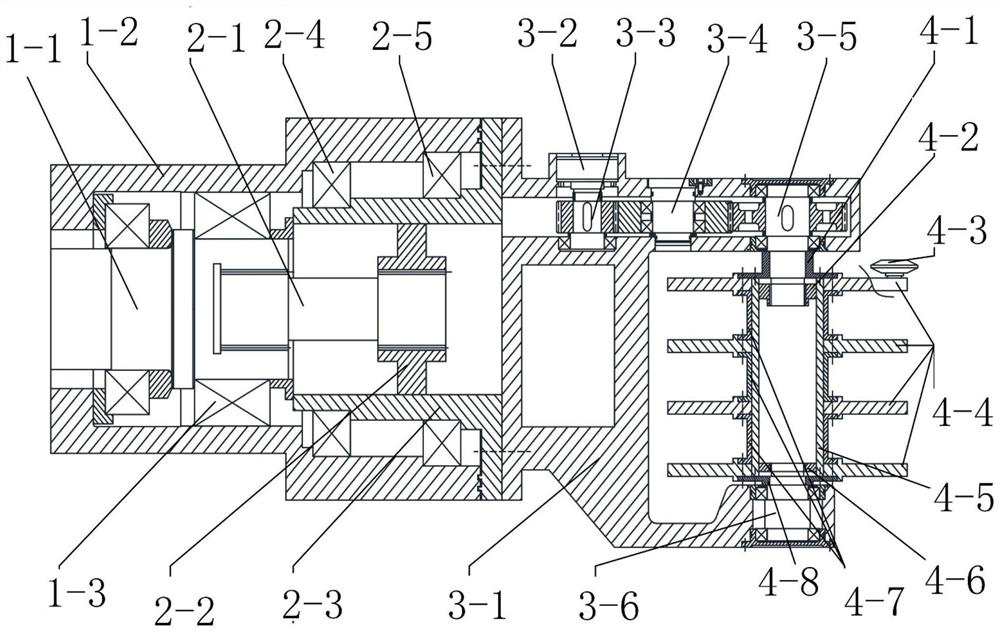

[0031] Such as Figure 1 to Figure 6 As shown, a disc crusher includes a rotary input device 1, a rotary connection device 2, a crushing support device 3 and a disc crushing device 4;

[0032] see image 3 The rotary input device 1 includes a rotary input housing 1-2, a rotary input shaft 1-1 is arranged inside the rotary input housing 1-2, and a support is provided between the rotary input shaft 1-1 and the rotary input housing 1-2. Bearing 1-3;

[0033] The rotating connection device 2 includes a rotating connecting sleeve 2-3 and a rotating connecting hub 2-2 fixed in the rotating connecting sleeve 2-3, and the rotating input housing 1-2 is sleeved on the outside of the rotating connecting sleeve 2-3. A connection bearing is provided between the rotation connection sleeve 2-3 and the rotation input housing 1-2; a through hole is provided on the rotation connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com