Raw coal bunker dynamic compensation processing system and method

A dynamic compensation and processing system technology, which is applied in the field of coal bunker filling, can solve problems such as coal measurement errors in different furnaces, and achieve the effect of accurate filling volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that those skilled in the art can make several changes and improvements without departing from the concept of the present invention. These all belong to protection domain of the present invention.

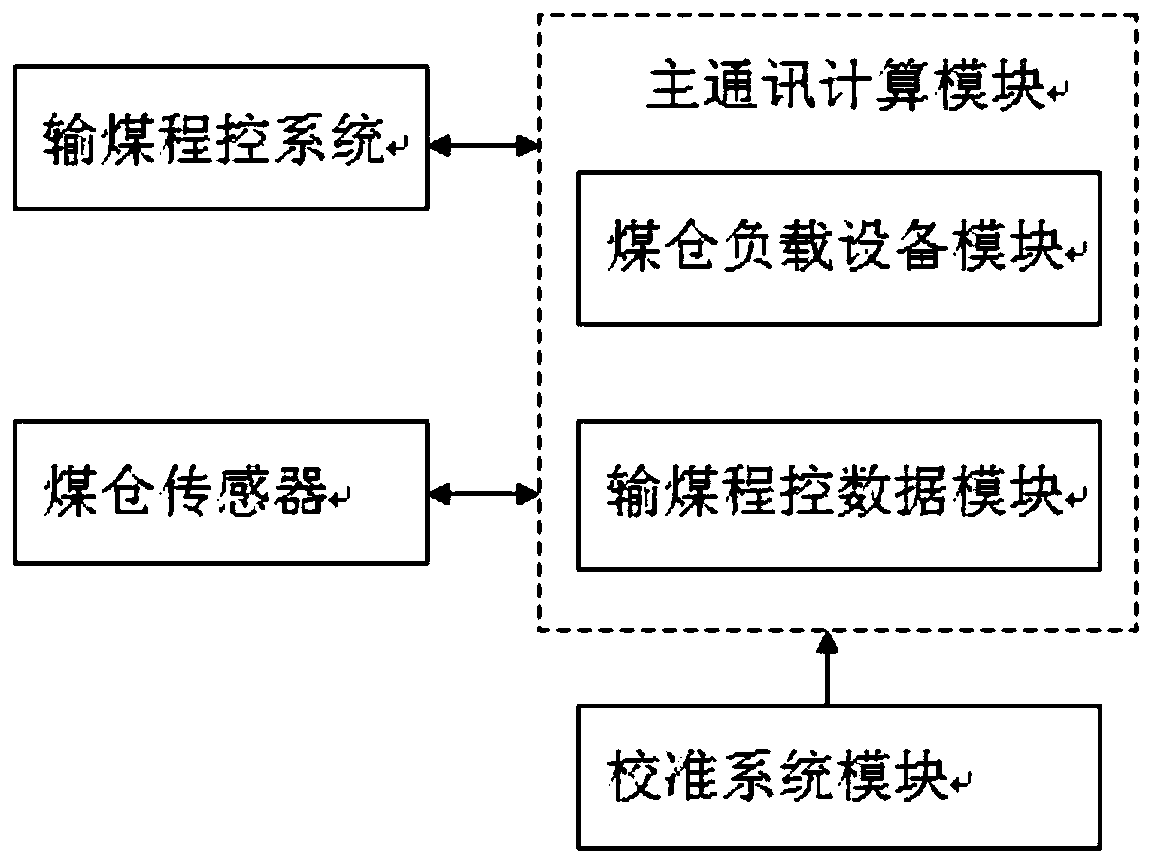

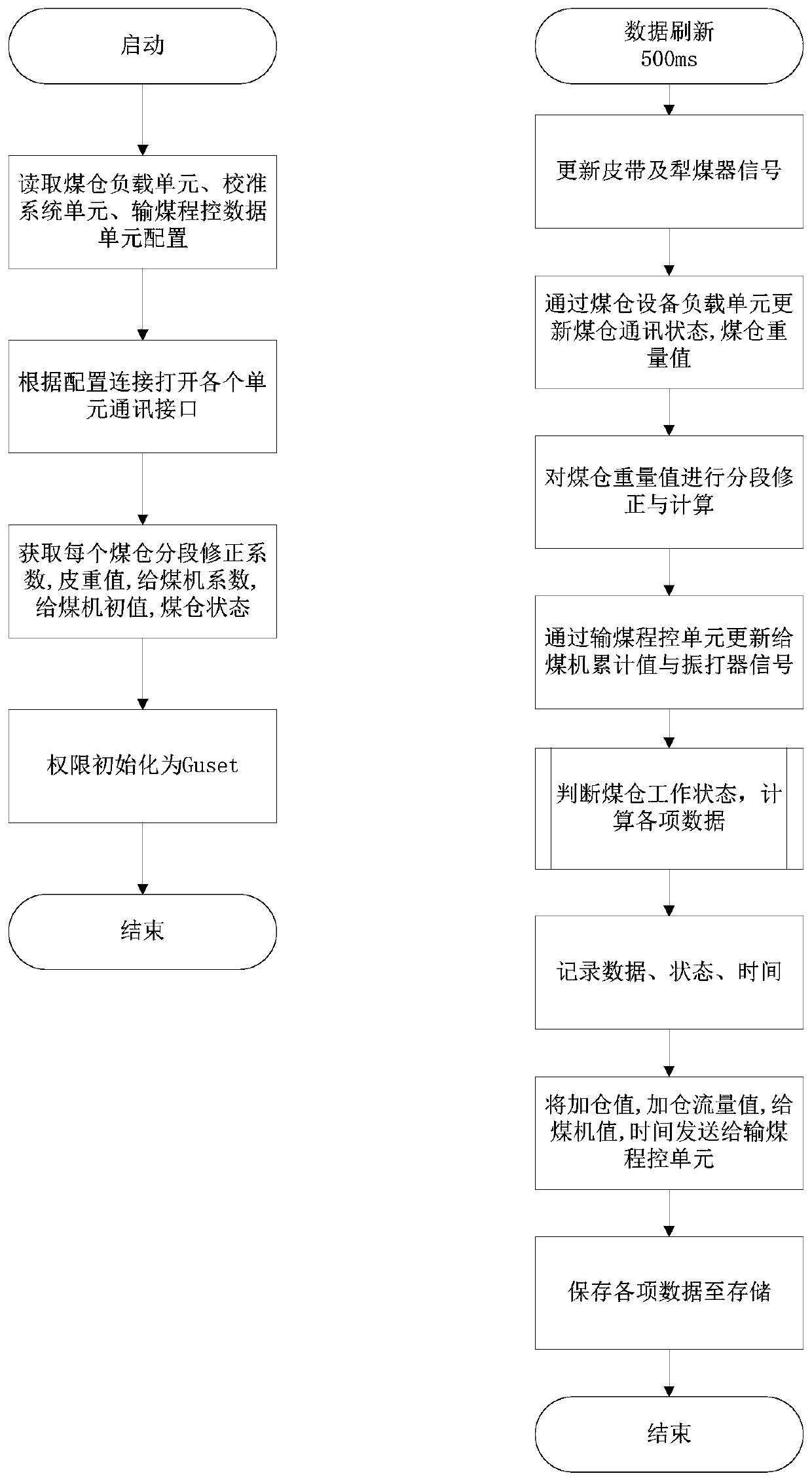

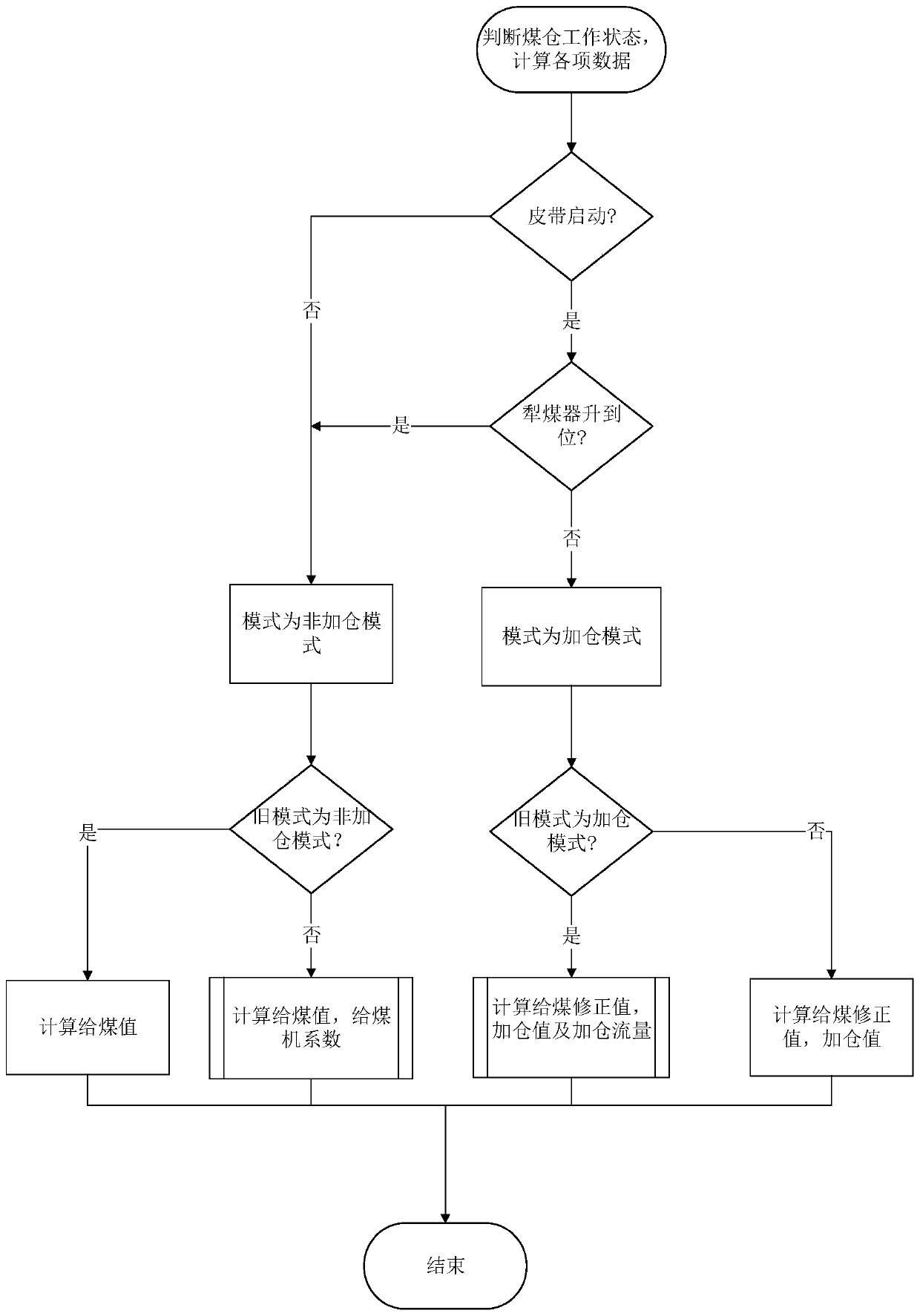

[0038] Such as Figure 1 to Figure 5 As shown, the present invention provides a dynamic compensation processing system and method for a raw coal bunker, combining a large-tonnage digital compensation load sensor with a traditional electronic hopper scale, judging the working mode of the coal bunker according to the field signal, and according to different modes Perform processing to obtain accurate warehouse addition and coal supply, and provide accurate warehouse addition data for thermal power plants to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com