Real-time state monitoring method and system for inspection robot and storage medium

An inspection robot, real-time status technology, applied in stereo systems, closed-circuit television systems, electrical components, etc., can solve problems such as difficulty for staff to understand the real-time status of the robot, inability to provide 360-degree viewing effects without dead ends, and improve efficiency. and quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

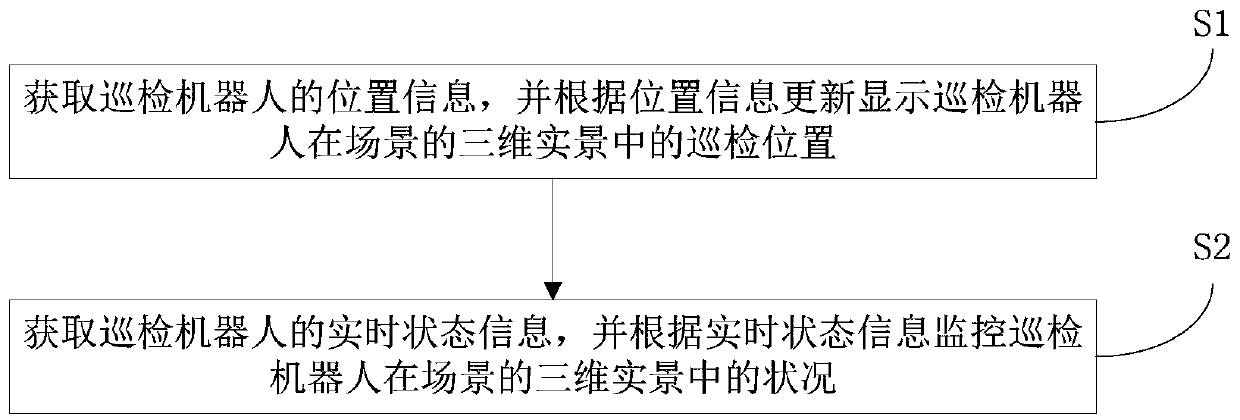

[0044] like figure 1 As shown, this embodiment provides a real-time state monitoring method for an inspection robot, including the following steps:

[0045] S1. Acquire position information of the inspection robot, and update and display the inspection position of the inspection robot in the three-dimensional real scene of the scene according to the position information.

[0046] S2. Acquire real-time state information of the inspection robot, and monitor the state of the inspection robot in the three-dimensional real scene of the scene according to the real-time state information. The 3D real scene of the scene is a 3D real scene video played based on the 3D real scene data of the scene.

[0047] In the method of this embodiment, a camera is installed on the inspection robot, and the inspection robot collects and uploads real-time video information of the substation while moving in the substation. The inspection movement mode of the inspection robot can be implemented in va...

Embodiment 2

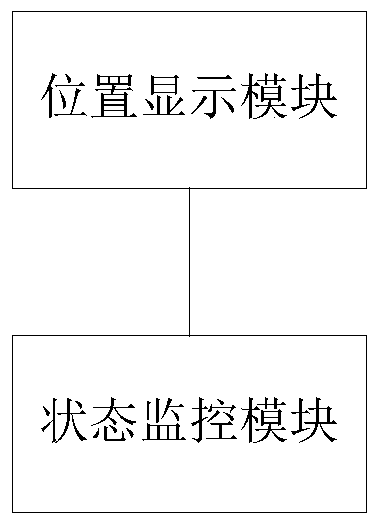

[0069] like figure 2 As shown, this embodiment provides a real-time state monitoring system for an inspection robot, including:

[0070] The position display module obtains the position information of the inspection robot, and updates and displays the inspection position of the inspection robot in the three-dimensional real scene of the scene according to the position information;

[0071] The status monitoring module obtains the real-time status information of the inspection robot, and monitors the status of the inspection robot in the three-dimensional real scene of the scene according to the real-time status information;

[0072] The 3D real scene of the scene is a real-time video stream showing the scene in the 3D model of the scene.

[0073] In the system of this embodiment, a camera is installed on the inspection robot, and the inspection robot collects and uploads real-time video information of the substation while moving in the substation. The inspection movement mo...

Embodiment 3

[0084] This embodiment provides a storage medium in which processor-executable instructions are stored, and when executed by the processor, the processor-executable instructions are used to execute the method described in the first embodiment.

[0085] A storage medium in this embodiment can execute the real-time state monitoring method for an inspection robot provided by the method embodiment 1 of the present invention, can execute any combination of implementation steps of the method embodiments, and has the corresponding functions and benefits of the method. Effect.

[0086] It should be appreciated that embodiments of the present invention may be implemented or implemented by computer hardware, a combination of hardware and software, or by computer instructions stored in non-transitory computer readable memory. The method can be implemented in a computer program using standard programming techniques - including a non-transitory computer-readable storage medium configured w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com