Anti-breakage and cut filter bottle structure based on chemical test

A technology for chemical test and suction filter bottle, which is applied to the field of suction filter bottle structure for preventing damage and cuts, can solve the problems of broken glass structure at the two bottle mouths, difficult to discharge outwards, and hidden safety hazards, and achieves improved functional characteristics, Reduce waste and improve anti-slip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

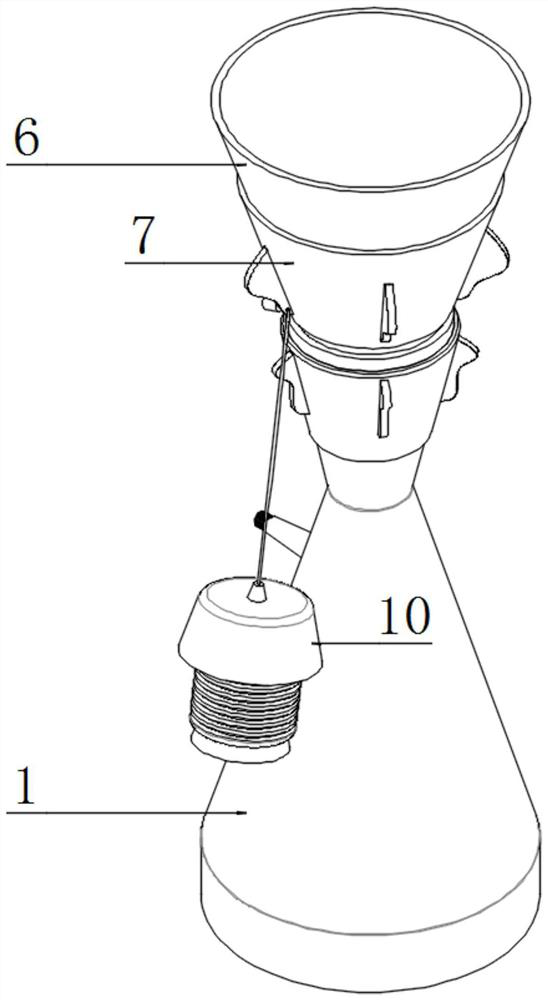

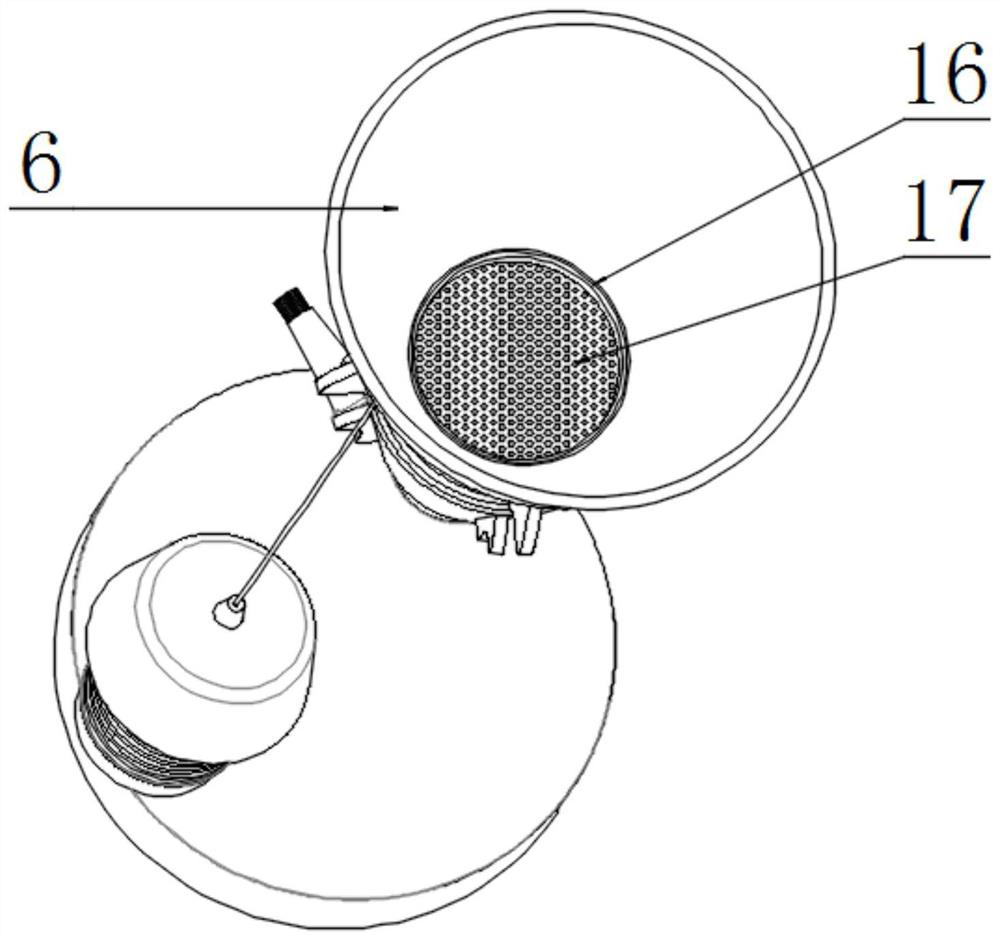

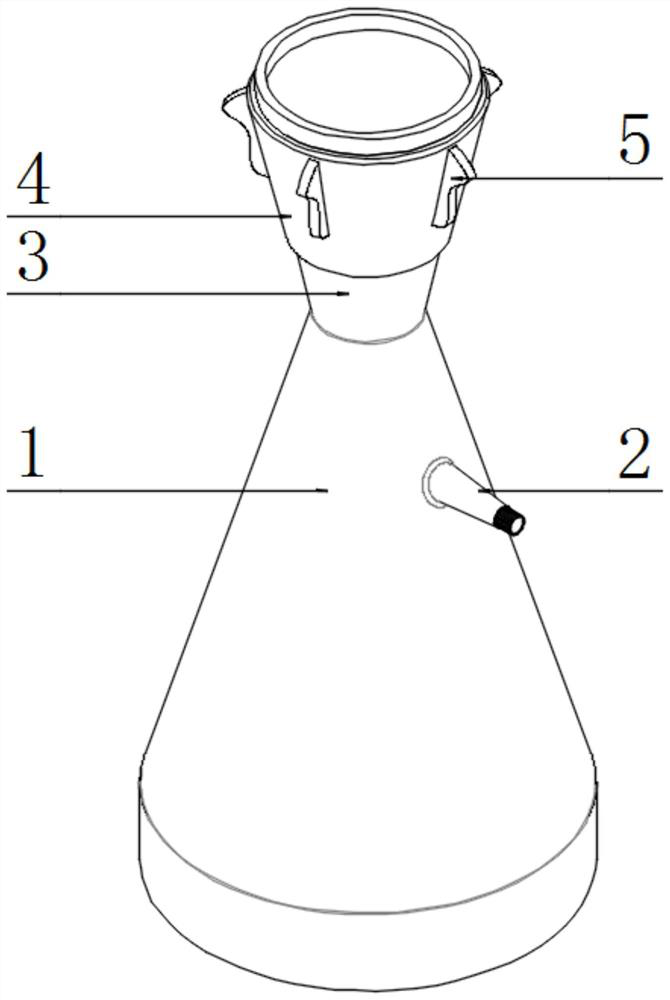

[0033] as attached figure 1 to attach Figure 9 Shown:

[0034] The present invention provides a damage-proof and cut-resistant suction filter bottle structure based on chemical tests, including a bottom bottle 1, a suction pump connecting pipe 2, a suction filter bucket nozzle 3, a nozzle protection ring 4, a first handle 5, and a suction filter bucket 6. Filter bucket retaining ring 7, second handle 8, pull cord 9, pressure capsule cover 10, pressure capsule cavity 11, perforation 12, retaining seat 13, rubber ring 14, buckle 15, suction filter cavity 16 and fine filter hole 17; The bottom bottle 1 is connected to the external suction pump through the suction pump connecting pipe 2 penetrated by one side, and a suction filter funnel 6 with a tapered funnel structure is inserted into the suction filter funnel cover 3 on the top of the bottom bottle 1 The pressure bag cover 10 is a hollow cavity structure, and its bottom is connected with a cylindrical corrugated cavity-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com