Concentration and dehydration process of ultra-fine tailings

A technology for concentration and dehydration and tailings, which is applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve problems such as affecting the safety of the dam body, low output concentration, and difficulty in settlement, so as to improve the utilization rate of tailings resources, filter The cake looseness is good and the effect of reducing tailings moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

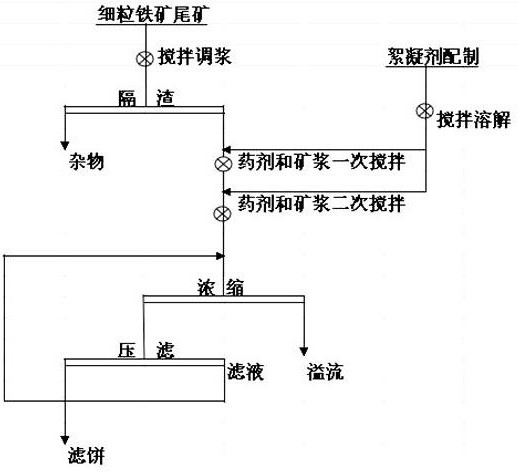

[0025] Embodiment 1: see figure 1 , a process for concentrating and dehydrating very fine tailings, said process comprising the following steps:

[0026] 1) Stir the tailings slurry to make it into a suspended slurry, which is easy to flow;

[0027] 2) Slag separation is carried out on the pulp after pulp adjustment to remove sundries;

[0028] 3), prepare flocculant, add the ore pulp after slag separation and stir and mix evenly twice;

[0029] 4) The flocculant is mixed with the pulp, and the pulp is concentrated by a high-efficiency thickener;

[0030] 5). The concentrated underflow is sent to the filter press for pressure filtration, and the overflow is clarified and used as industrial circulating water.

[0031] This technical solution greatly reduces the moisture content of the tailings, the filter cake is loose and does not need to be broken up, the forklift shovel does not stick to the bucket, the car transport unloads the material without sticking to the box, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com