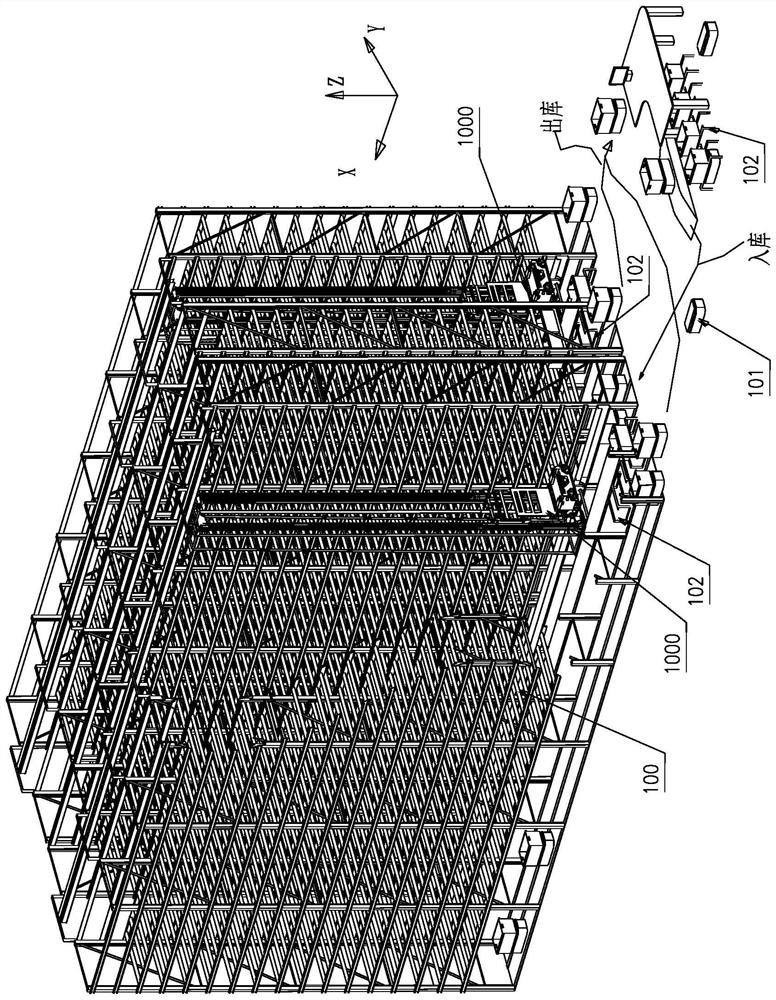

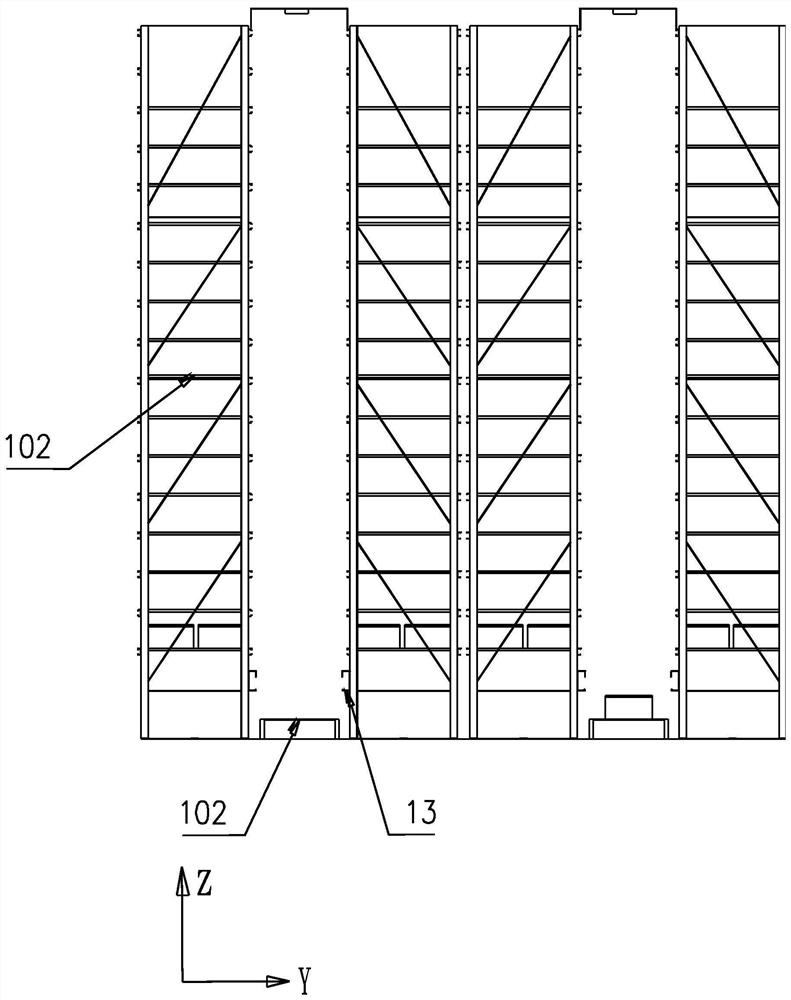

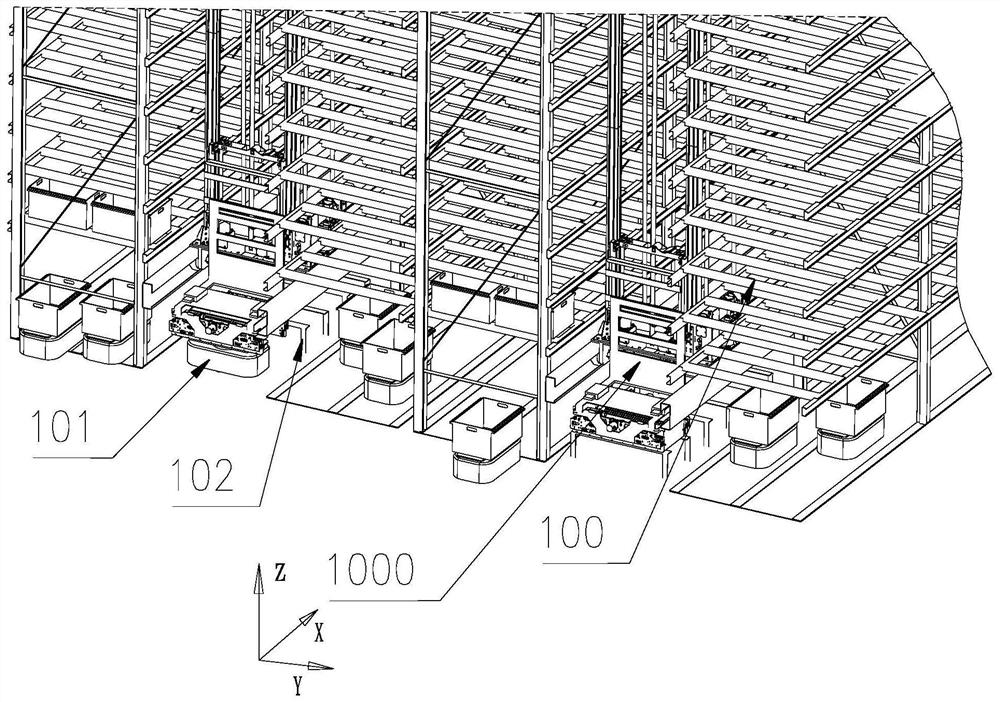

A warehouse logistics system

A warehousing logistics and control system technology, applied in the field of warehousing and logistics, can solve the problems of slow promotion and application, waste of equipment costs, etc., and achieve the effect of improving transportation efficiency and reducing excessive travel time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0063] In this preferred embodiment, the structural shape of the power tooth plate 316 can be divided into three layers, the top layer is the transmission rack 3161, the middle layer is the installation position of the telescopic synchronous belt 3112, and the lower layer is the first slide rail assembly 318 and the second The installation position of the slide rail assembly 3110, wherein two ends of the middle layer are provided with mounting holes for telescopic transmission wheels 3113, and two telescopic transmission wheels 3113 are respectively installed therein. Since one end of the telescopic synchronous belt 3112 is fixed to the fixed plate 311, and the other end is fixed to the telescopic plate 3111, when the power gear plate 316 moves to one side, it will be driven by the telescopic synchronous belt 3112, using the principle of a movable pulley , to drive the expansion plate 3111 to expand and contract again. This structure is not only reasonable and compact, but also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com