Heat treatment equipment for automobiles

A kind of heat treatment equipment and automobile technology, which is applied in the field of auto parts processing, can solve the problems of single function, easy to be burned, stuck, etc., and achieve the effect of reducing friction and avoiding burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

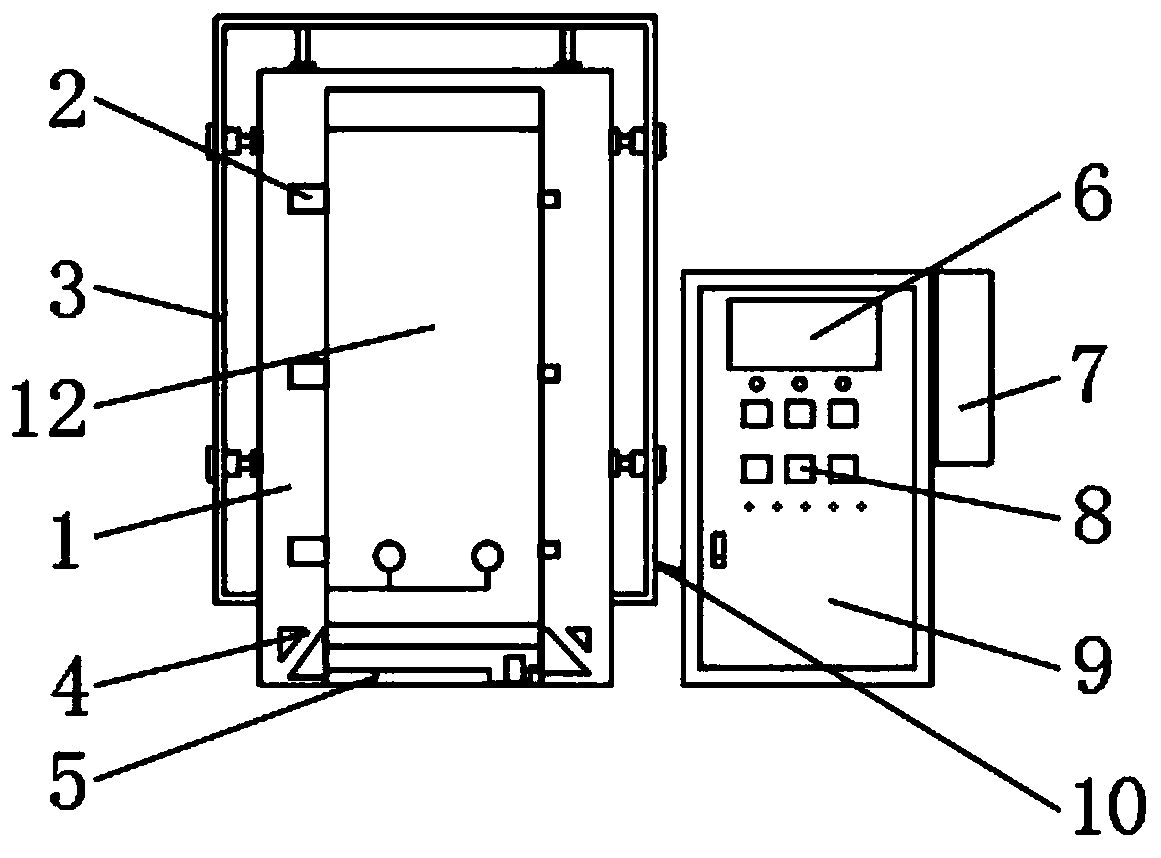

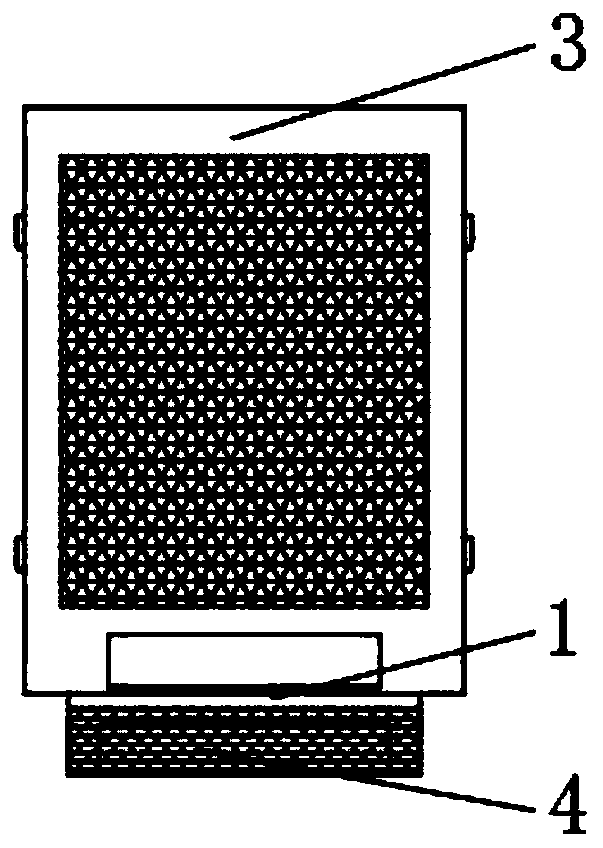

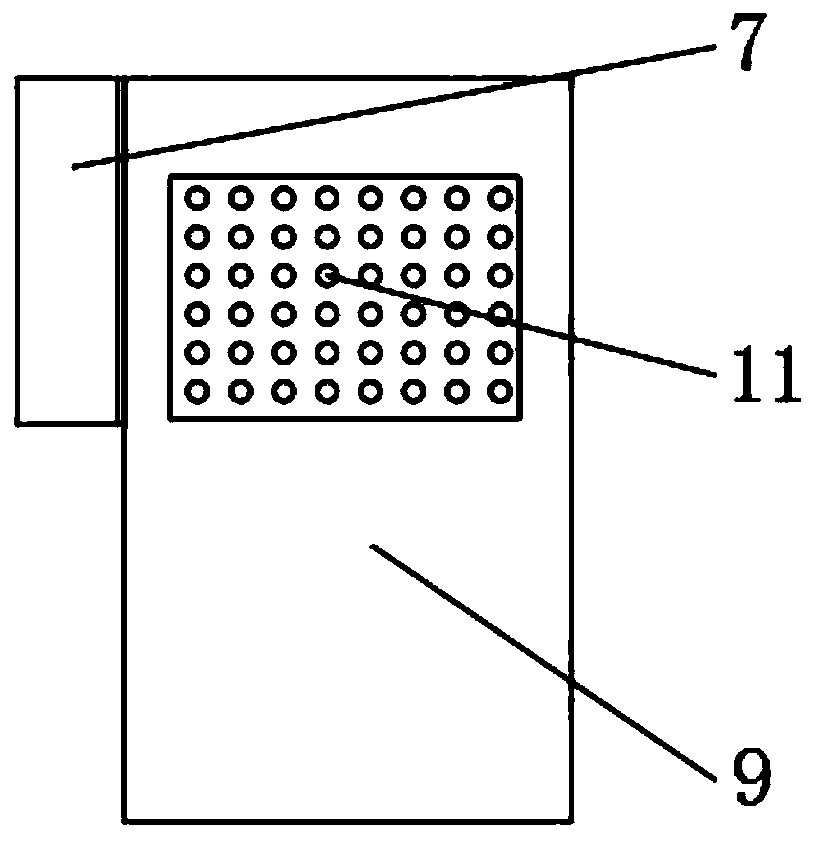

[0027] see Figure 1-7 , the present invention provides a technical solution: comprising a heat treatment equipment casing 1 and a computer control host 9, the outer surface of the heat treatment equipment casing 1 is fixedly equipped with an anti-scald dustproof cover mechanism 3, and the outer surface of the lower end of the heat treatment equipment casing 1 is provided with a push-out prevention The card mechanism 5 and the outer surface of one side of the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap