Fatigue test bed for automobile suspension system

A technology for automotive suspension and fatigue testing, which is applied in the testing of vehicle suspension/shock absorbing mechanisms, etc., can solve the problems of high test cost, short test time, and long test time, and achieve good versatility, shortened time, and reliable performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

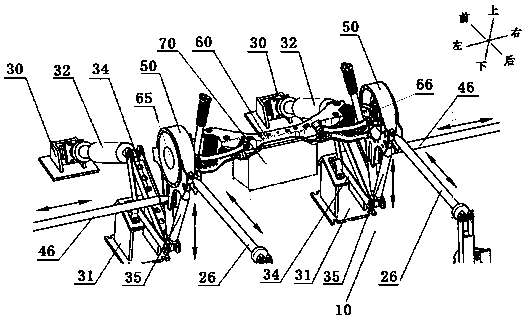

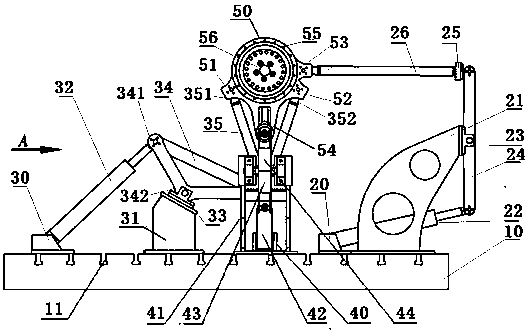

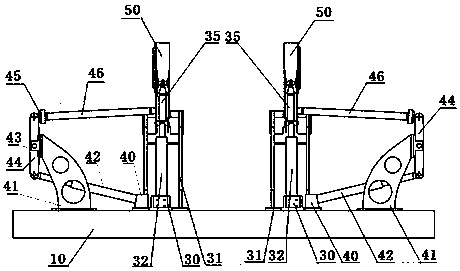

[0034] The present invention is further described below in conjunction with accompanying drawing:

[0035] refer to Figure 1 to Figure 5 A kind of fatigue test bench of automobile suspension system shown, comprises test bench plate 10, and its central part is provided with fixed reaction force bracket 70; On the reaction force bracket 70, the automobile suspension system 60 includes a left brake 65 and a right brake 66; it is characterized in that:

[0036] Two tire simulation fixture assemblies with exactly the same structure are respectively connected to the left and right ends of the automobile suspension system 60;

[0037] Two longitudinal loading assemblies with identical structures are fixedly connected to the rear of the test bench plate 10, and are left-right symmetrical about the fixed reaction force bracket 70;

[0038] Two vertical loading assemblies with identical structures are fixedly connected to the front part of the test bench plate 10, and are left-right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com