Reducing pipeline crack detection equipment

A crack detection and pipeline technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of inconvenient movement, invisibility, and robots cannot be effectively avoided, and achieve the effect of avoiding contact pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

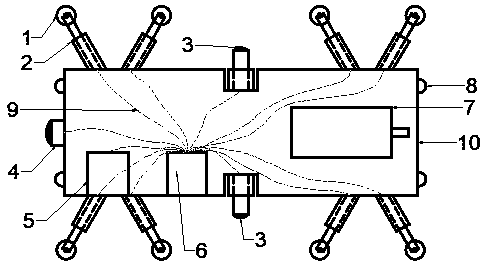

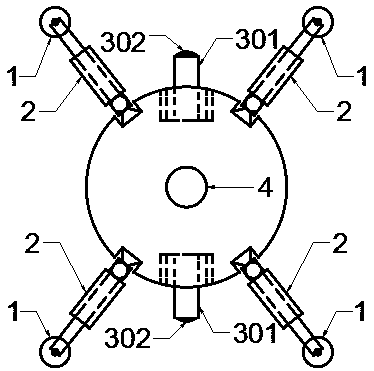

[0014] The invention discloses a variable diameter pipeline crack detection equipment, which includes a walking wheel 1, a steerable telescopic connecting rod 2, a telescopic pressure sensor system 3, a telescopic connecting rod 301, a pressure sensor 302, a three-dimensional scanning system 4, and a signal processing system 5. Power system 6. Circumferential radiation X-ray flaw detector 7. Hook 8. Wire 9. Shell 10. The three-dimensional scanning system 4 is arranged on the left side of the housing 10. The upper and lower parts of the housing 10 are provided with a steerable telescopic link 2 through articulation. The steerable telescopic link 2 is equipped with a walking wheel 1. The device has a retractable pressure sensor system 3, and a circumferential radiation X-ray flaw detector 7 is located in the right center of the housing 10. A signal processing system 5 is provided on the left side of the housing 10, and a power system 6 is provided on the right side of the signal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com