Display screen back plate based on flame retardant material and LED display screen

A technology of LED display screen and display screen, which is applied in the field of splicing screen, which can solve the problems of inconvenient storage and transportation, complex assembly structure, slow installation speed, etc., and achieves convenient roll-up storage and transportation, convenient assembly of backplane, and good heat dissipation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

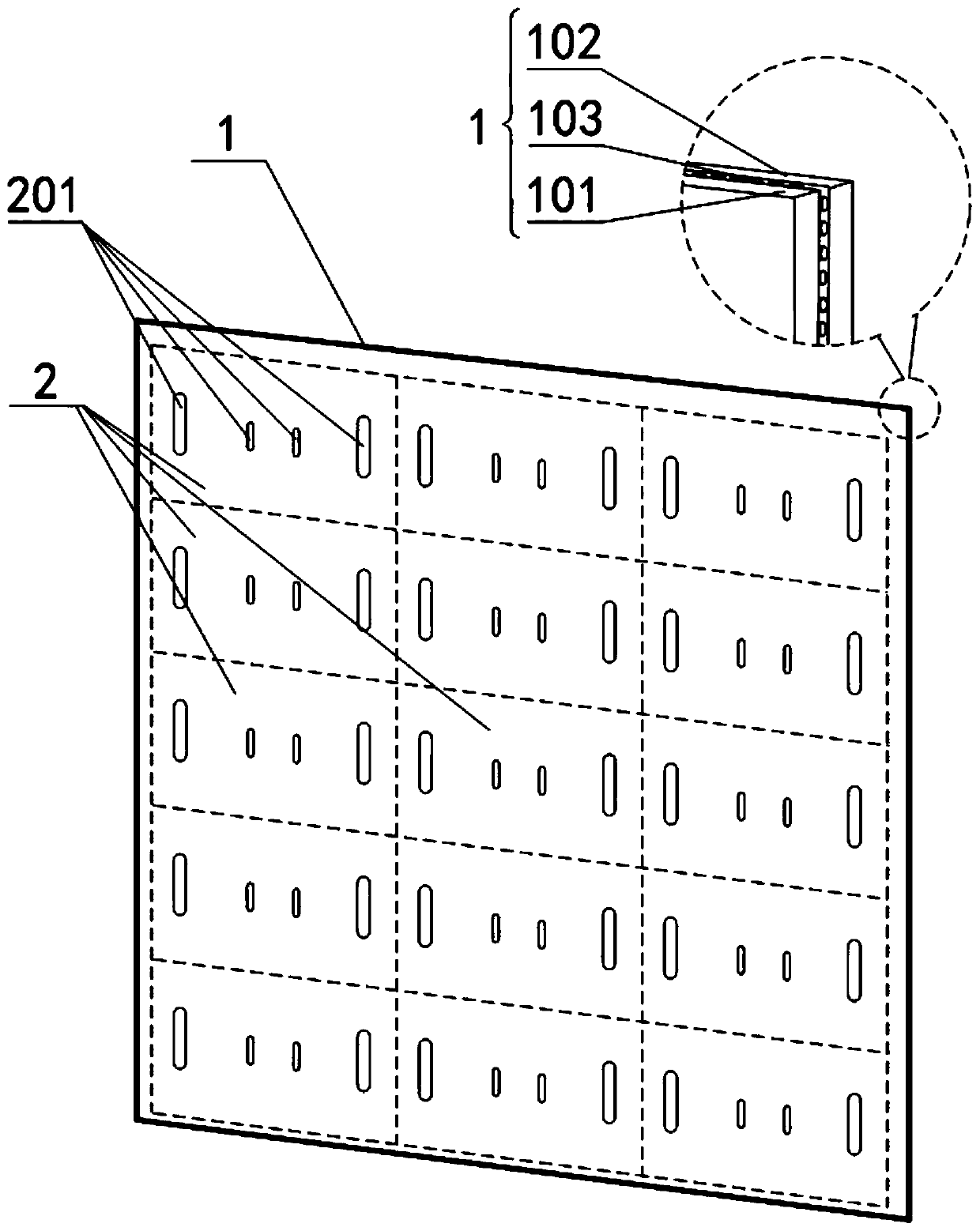

[0044] Such as Figure 1~3 As shown, the display backplane based on flame-retardant material provided in this embodiment includes a backplane body 1, wherein the backplane body 1 is composed of first flame-retardant material layers 101 arranged in sequence from front to back. 1, a metal mesh layer 103 and a second flame-retardant material layer 102; on the main viewing surface of the backplane body 1, there are several module installation areas 2 arranged vertically and horizontally for hanging display modules.

[0045] Such as Figure 1~3 As shown, in the specific structure of the display screen backboard, the backboard body 1 is used to replace the rectangular steel frame to mount a plurality of display screen modules (which can be but not limited to LED display screen modules or liquid crystal display module, etc.); because it is composed of two flame-retardant material layers 101 at the front and rear and a metal mesh layer 103 in the middle, the backplane body 1 can have...

Embodiment 2

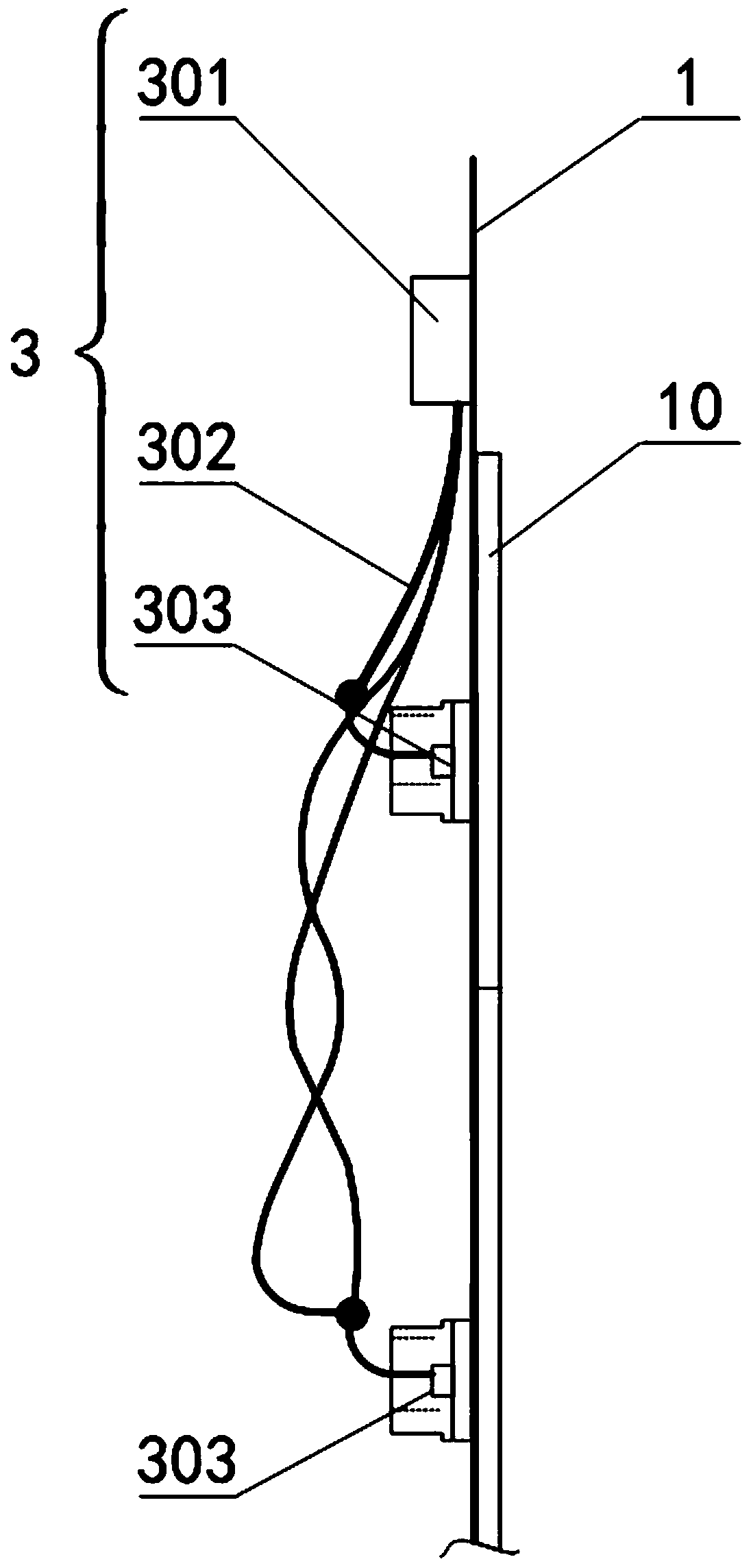

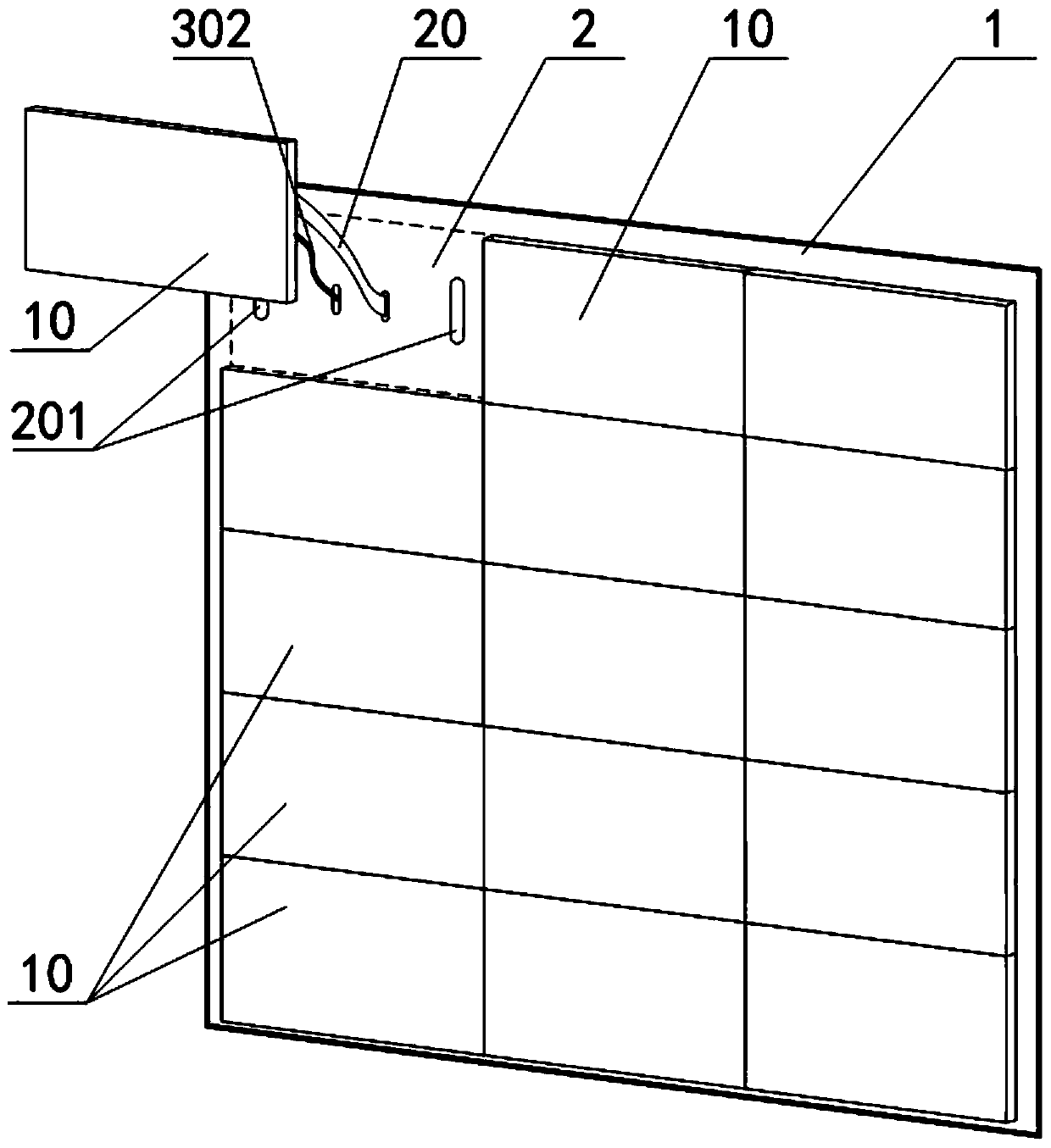

[0056] Such as Figure 3-6 As shown, this embodiment provides an LED display based on the display backplane based on the flame-retardant material described in Embodiment 1. In addition to including the display backplane based on flame-retardant material as described in Embodiment 1, it also It includes an LED display module 10, a signal plug, a mains plug, an AC / DC conversion power supply and a DC / DC step-down power supply; the number of the LED display module 10 is several and they are mounted in one-to-one correspondence. On the module installation area 2 of the display screen backplane, and spliced to form a whole display area; the signal plugs include video signal plugs, wherein the video signal plugs communicate with each other through the module signal line 20 The signal input end of the LED display module 10; the mains plug is electrically connected to the input end of the AC / DC conversion power supply, and the output end of the AC / DC conversion power supply is electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com