Winding device

A winding device and winding machine technology, applied in coil manufacturing, electrical components, inductance/transformer/magnet manufacturing, etc., can solve the problems of low enameled wire tightness adjustment accuracy and affect coil quality, etc., and achieve good adjustable effect , Simple structure, avoid the effect of loose thread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

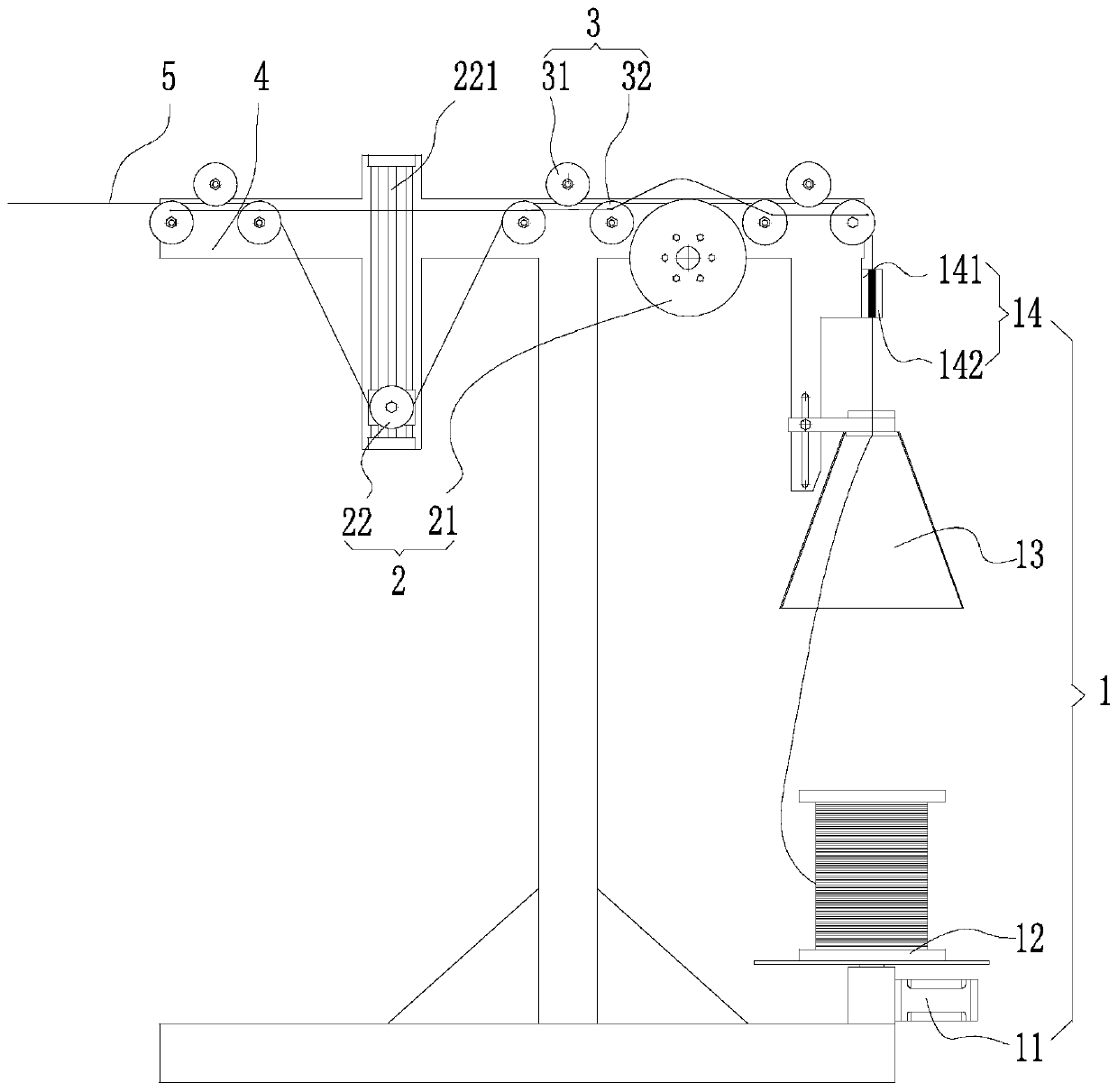

[0028] Furthermore, please also refer to figure 1 and figure 2 , as a specific embodiment of the wire winding device provided by the present invention, the pay-off assembly 1 further includes an anti-swing wire cover 13 , and the enameled wire 5 passes through the anti-swing wire cover 13 . Specifically, the wire speed of the winding machine of the automatic high-voltage coil is relatively high, and the phenomenon of wire throwing may occur when the first rotating drive member 11 drives the wire reel 12 to unwind, and the thicker the diameter of the enameled wire 5, the greater the throwing force. It directly affects the work of the winding machine and the quality of the enameled wire 5, and the anti-swing wire cover 13 can effectively prevent the external swing to ensure production safety and the work of the winding machine. Wherein, the anti-swing wire cover 13 can be a protective cover sheathed on the outside of the enameled wire 5, so as to avoid external swinging.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com