An automatic assembly system for motor rotor

A motor rotor and automatic assembly technology, applied in the direction of adjusting/balancing the rotor, etc., can solve the problems of long production time, low degree of automation, and large floor space, so as to reduce the dependence on labor, improve the degree of automation, and occupy space small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

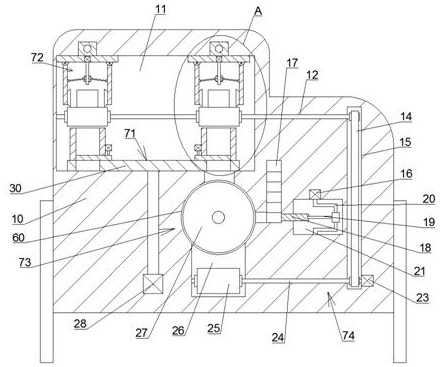

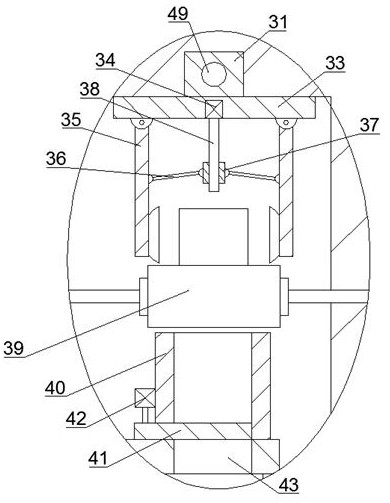

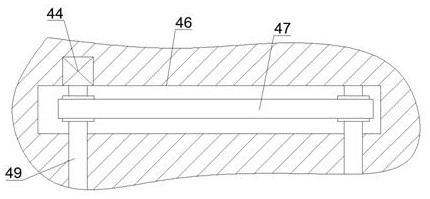

[0016] Combine below Figure 1-4 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0017] refer to Figure 1-4 , according to an embodiment of the present invention, an automatic assembly system for motor rotors includes a main body 10, and a feeding chamber 11 is opened in the main body 10, the rear side of the feeding chamber 11 is designed as an opening, and the upper A feeding mechanism 71 is provided in the material chamber 11, and the material feeding mechanism 71 includes a rotating disk 30 on which the motor rotor and the motor stator can be stored temporarily. Holding mechanism 72, said holding mechanism 72 comprises two groups of left and right symmetrical slide plates 33, and the bottom of said slide plates 33 is hinged with two sets of clamping rods 35, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com