Construction process of inner tank top plate in low temperature storage tank and construction process of low temperature storage tank

A construction technique and low-temperature storage tank technology, applied in the direction of manufacturing tools, metal processing equipment, auxiliary devices, etc., can solve the problems of difficult control of the construction quality of the inner tank roof, low safety factor, high economic cost, etc., and achieve safe and controllable construction quality , simple method, reasonable process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

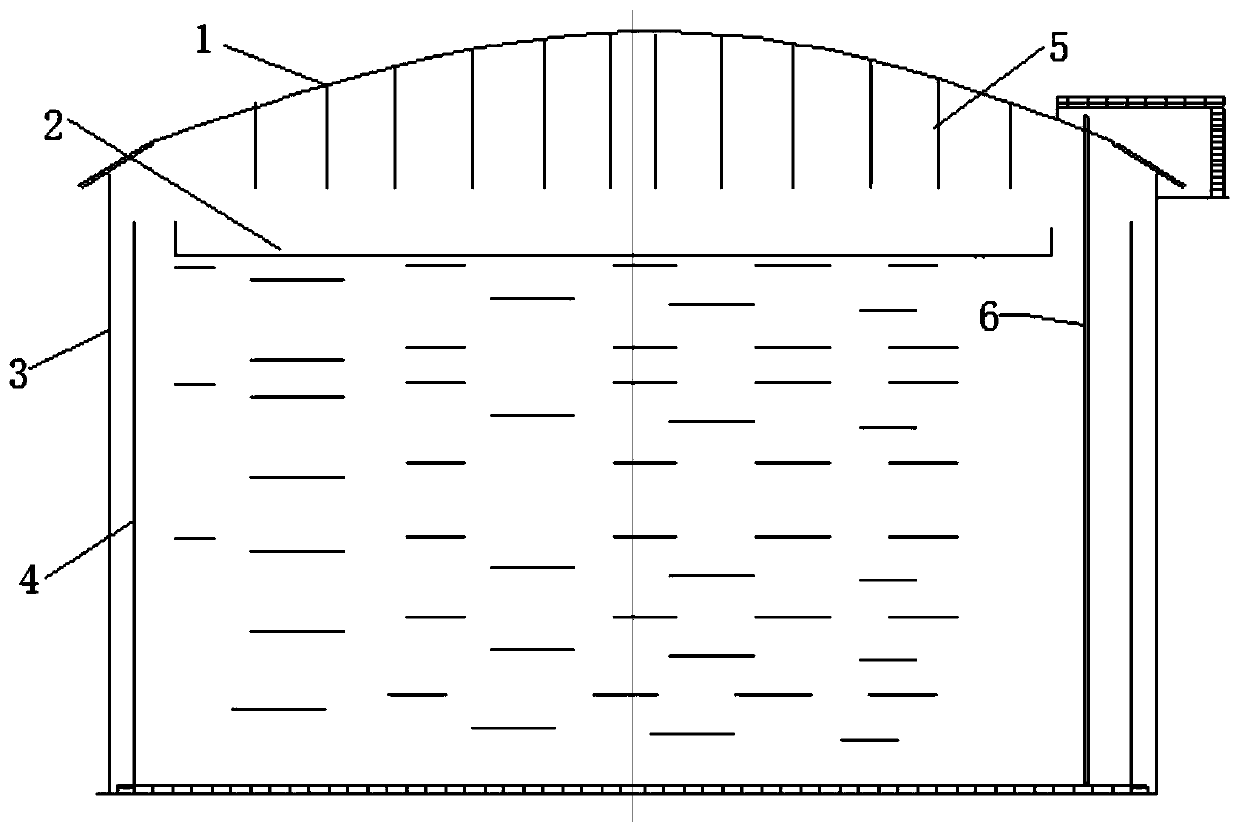

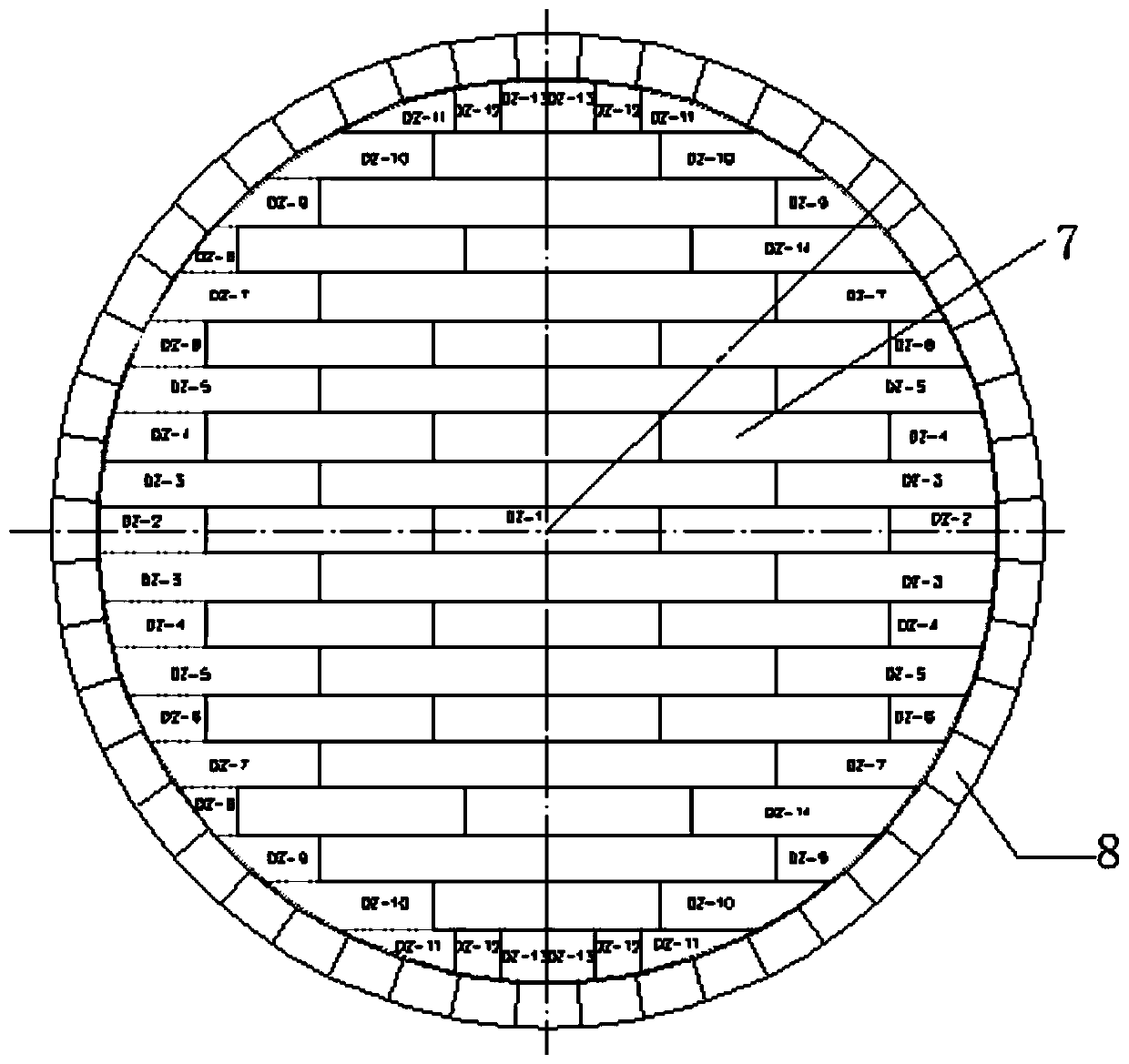

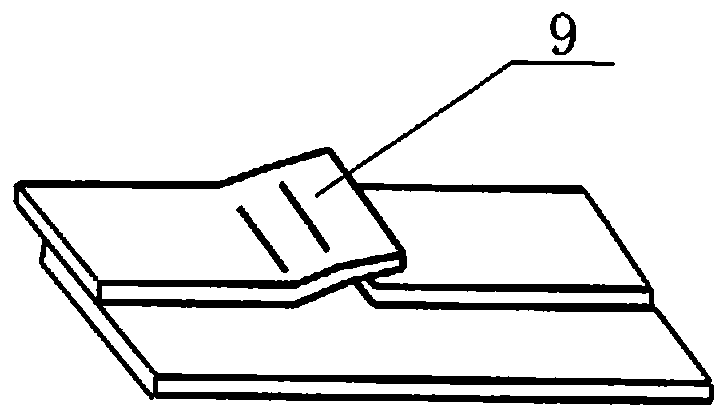

[0050] In a typical embodiment of the present invention, such as figure 1 As shown, a construction process of the inner tank roof of a low-temperature storage tank, the inner tank roof 2 is floated to the installation position by using the tank body hydraulic pressure test, and then installed to the elevation position.

[0051] Specifically include the following:

[0052] The 3 wall panels of the outer tank and the 4 wall panels of the inner tank have been installed, and the position of the first wall panel of the inner and outer tanks is reserved for the entrance and exit gate (temporary gate);

[0053] Before the dome of the outer tank 3 is installed, the tie rod 5 of the roof plate 2 of the inner tank is installed on the dome beam of the outer tank, and is installed together with the dome of the outer tank;

[0054] The bottom of the outer tank, the bottom of the tank and the bottom of the inner tank have been constructed, and the bottom of the outer tank and the bottom of...

Embodiment 2

[0096] The invention also provides a low-temperature storage tank construction process, such as Figure 5 shown, including the following:

[0097] The inner and outer tank bottom plates are prefabricated, and the outer edge plates are laid and welded;

[0098] The laying and welding of the outer middle plate, and the welding of the first and second rings of the outer tank wall plate at the same time;

[0099] Three seam assembly welding at the bottom of the outer tank;

[0100] Construction of inner tank bottom ring beam;

[0101] Welding of inner tank bottom edge;

[0102] Welding of the first and second ring wall panels of the inner tank;

[0103] The pipe walls of the inner and outer tanks are prefabricated, and the inner and outer tanks are assembled and welded alternately except for the first and second circles of wall panels;

[0104] Prefabrication of tank roof pressure ring, installation of tank top pressure ring and tank inner pipe;

[0105] The melon slices on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Perimeter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com