Automatic rotating conveying module

A module and camera module technology, applied in the direction of conveyors, conveyor objects, cleaning devices, etc., can solve problems such as low precision, large measurement errors, and affecting detection results, achieving strong versatility and avoiding the impact of cleanliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

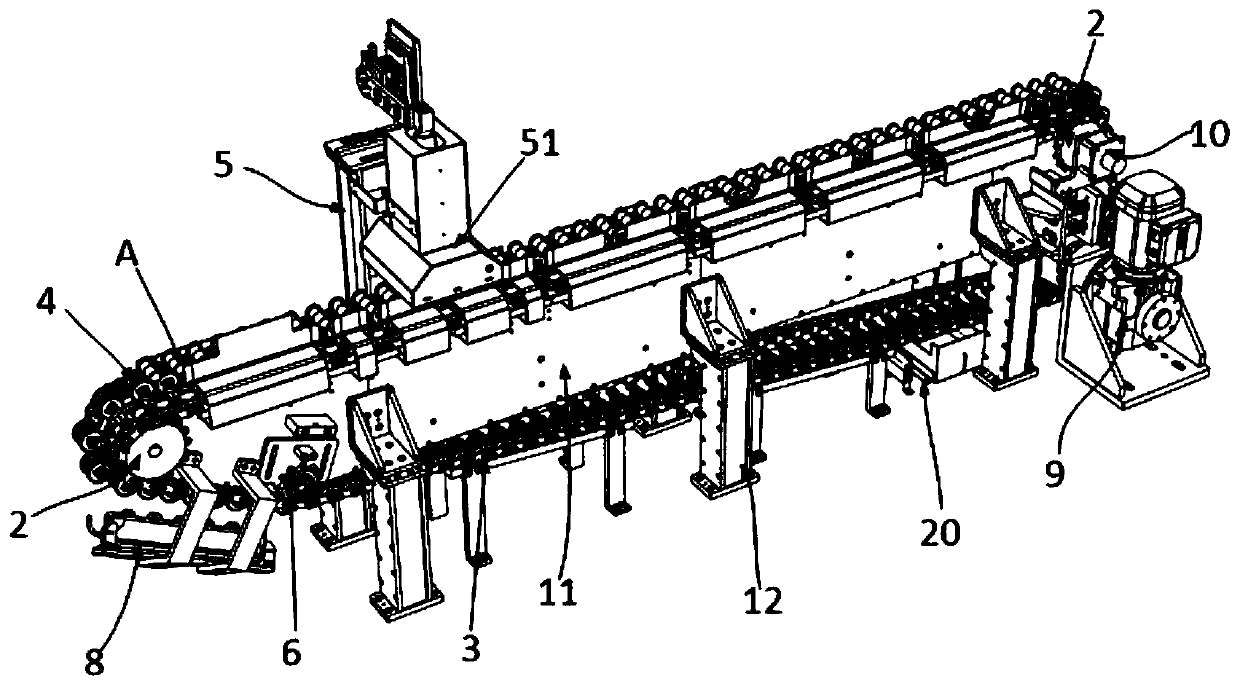

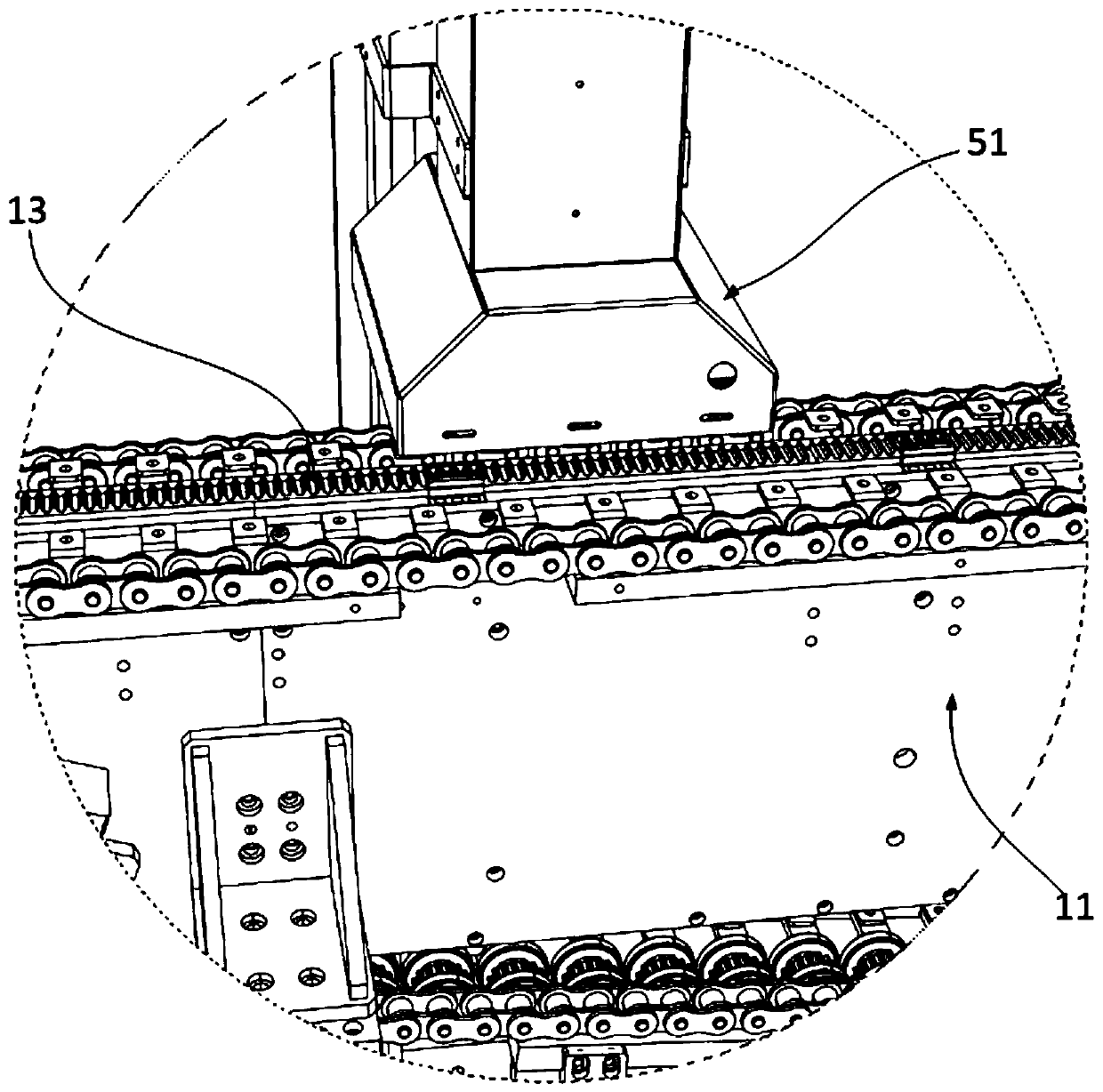

[0062] This embodiment provides an autotransformable transfer module, such as Figure 1-4 shown, including:

[0063] A frame, which includes a strip-shaped frame body 11 and support legs 12 fixed on both sides of the body 11;

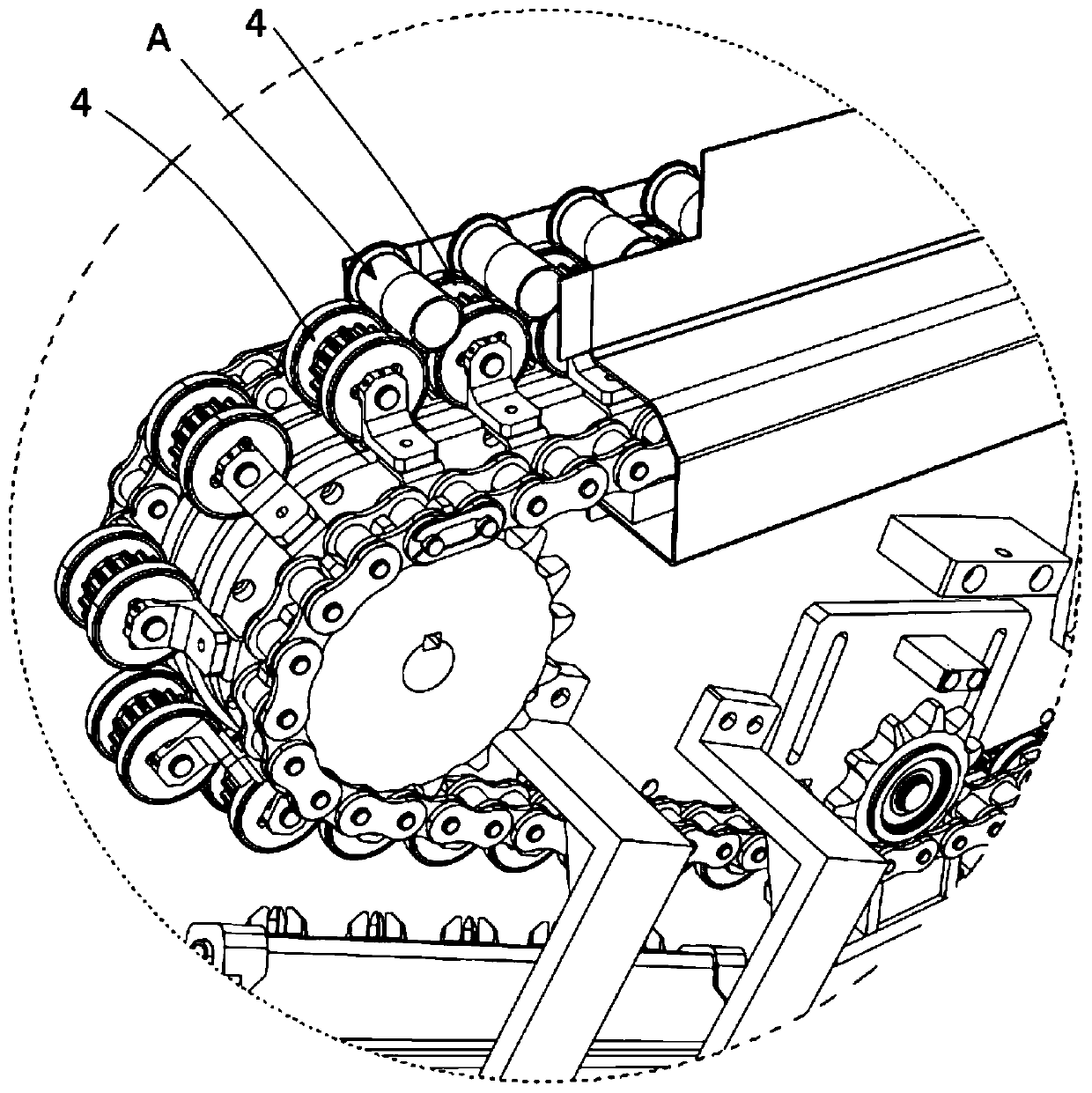

[0064] The sprockets 2 are arranged in pairs at each corner of the frame body 11 and can rotate, and each pair of sprockets 2 is divided into two that are separated from each other on both sides of the frame body 11;

[0065] The chain 3 is divided into two separated on both sides of the frame main body 11, which are sequentially connected with the sprockets 2 on both sides of the frame main body 11;

[0066] The drive device 9 is used to drive the assembly of the sprocket 2 and the chain 3 to move, and the drive device 9 is connected to one of the sprocket 2;

[0067] Several rollers 4 arranged side by side, the rollers 4 include two wheel bodies 41, gears 42, "L" shaped fixing seats 43 on both sides, and shaft cores 44, the gears 42 are fixed between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com