Pavement comprehensive maintenance vehicle

A technology for maintaining vehicles and car chassis, applied in the direction of roads, roads, road repair, etc., can solve the problems of cumbersome processing process, increased transportation costs, low fuel utilization rate, etc., to reduce labor intensity, reduce transportation costs, and save fuel use. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

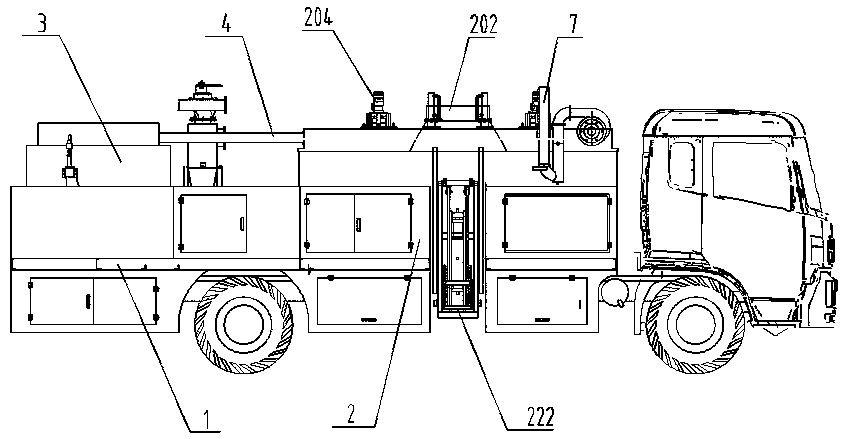

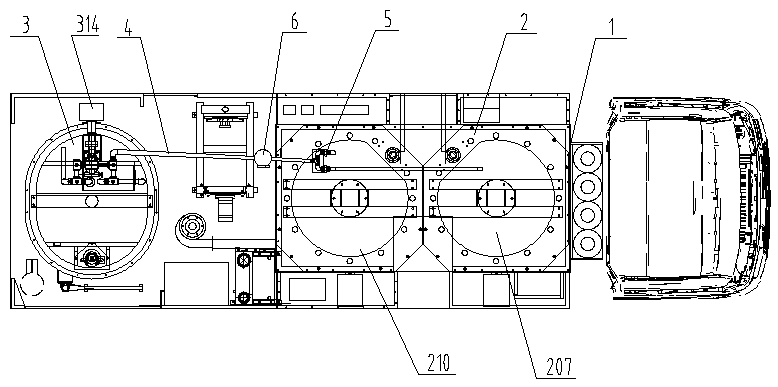

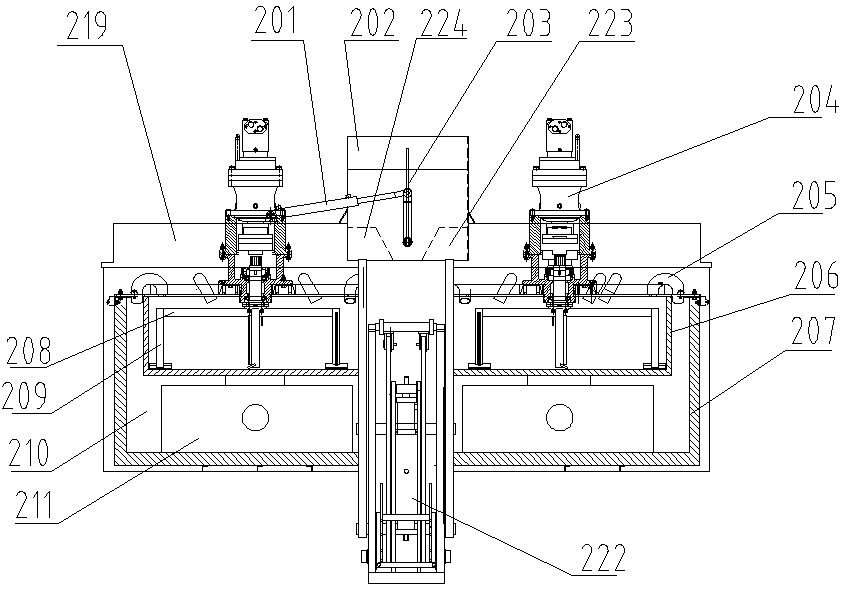

[0024] refer to Figure 1-8 , a comprehensive road surface maintenance vehicle, comprising a car chassis, a mixing bin and an asphalt box arranged on the car chassis, an asphalt conveying pipeline is arranged between the asphalt box and the mixing bin, and the mixing bin 2 includes a Front storehouse body 207 and rear storehouse body 210 on the chassis, the upper end of front storehouse body 207 and rear storehouse body 210 buckles a storehouse cover 219, and storehouse cover 219 top side is provided with a material receiving chute 202, and the lower end of material receiving chute 202 A front blanking port 223 and a rear blanking port 224 are provided, and the front blanking port 223 and the rear blanking port 224 are connected to the front bin body 207 and the rear bin body 210 respectively. The material ram 203, the lower end of the material distribution ram 203 is fixedly connected with the rotating shaft that is arranged between the front blanking port 223 and the rear bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com