Anti-falling steel purlin conversion device

A technology of conversion device and steel purlin, which is used in excavation, construction, infrastructure engineering and other directions to achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in combination with specific embodiments.

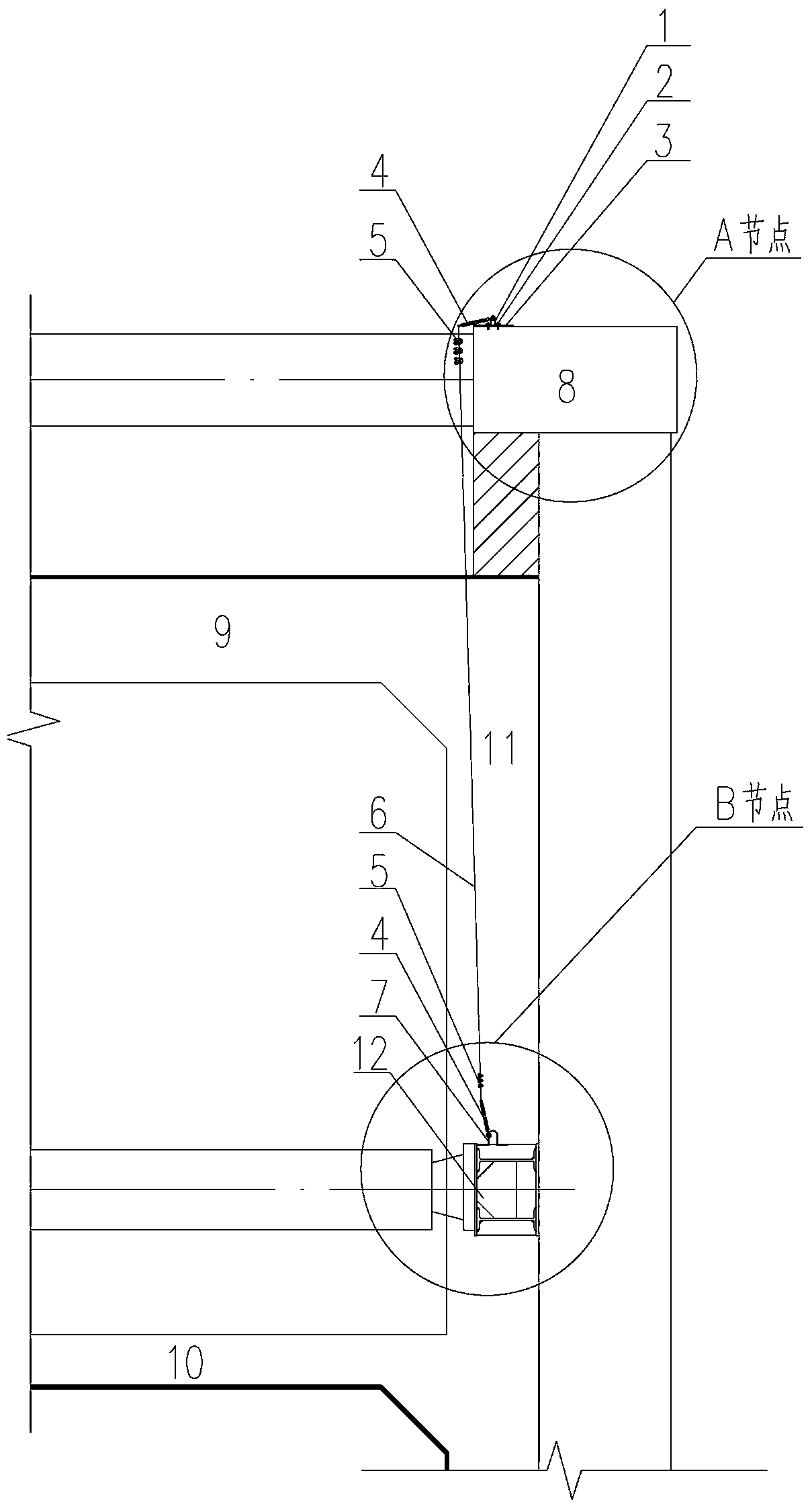

[0022] The invention relates to a steel purlin fall prevention conversion device, comprising the existing crown beam 8 and the existing steel purlin 12 in the pile support system of the underground open excavation station, and the existing crown beam 8 and the existing steel purlin A steel wire rope 6 is arranged between 12, and the upper and lower ends of the steel wire rope 6 are respectively fixed to the top of the existing crown beam 8 and the top of the existing steel purlin 12 through fixing components, forming a bridge between the existing crown beam 8 and the existing steel purlin 12. effective connection.

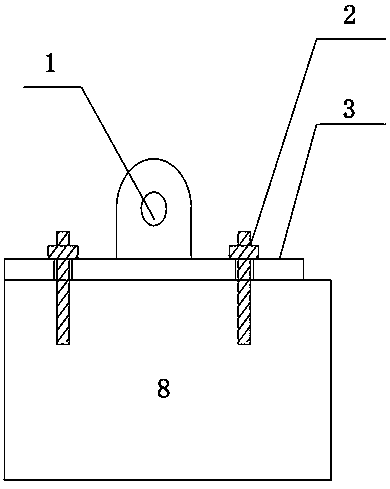

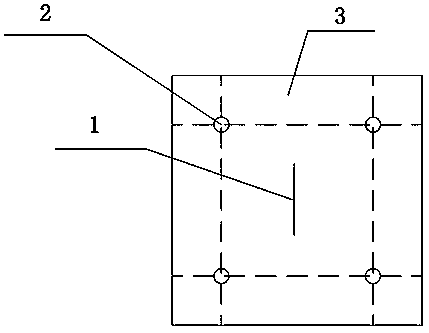

[0023] The top of the existing crown beam 8 is provided with a pre-embedded steel plate 3, which is fixed to the existing crown beam 8 by expansion bolts 2, and the surface of the pre-embedded steel plate 3 is welded with a lifting lug 1 as a fixed node at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com