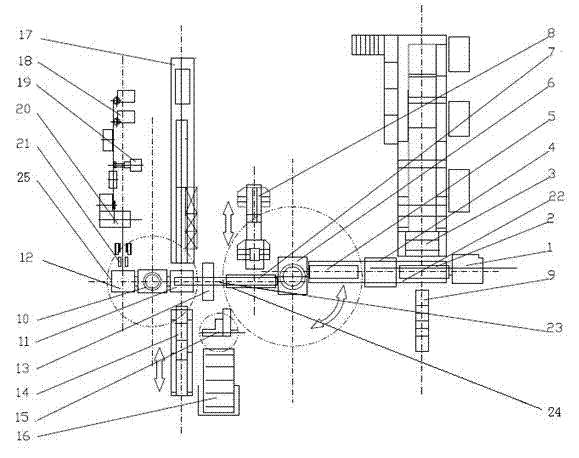

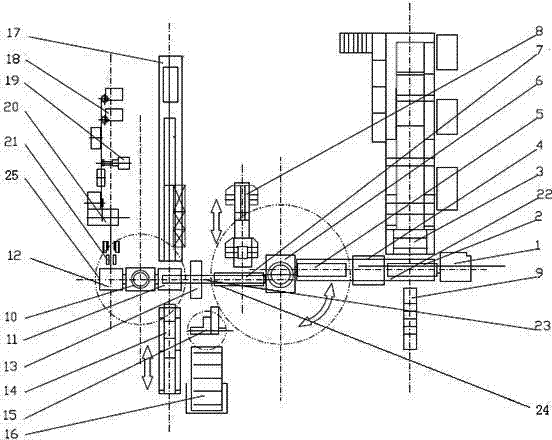

Once-forming technology and once-forming device of belt wound type five-drum all-steel radial ply tire

A technology of radial tires and forming devices, which can be applied to tires, other household appliances, household appliances, etc., can solve problems affecting tire dynamic balance and uniformity, and achieve the effect of improving dynamic balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiment of the present invention: belt winding five-drum all-steel radial tire one-shot molding process, the sidewall, inner liner, slit reinforcing layer, slit wrap, carcass cord, shoulder The pad rubber and the steel traveler are bonded together to form the carcass tube A; the carcass tube A is transferred to the forming drum at the forming drum I station through the carcass transfer ring, and the forming drum chassis rotates the forming drum and the carcass tube A to the Waiting at the forming drum II station; respectively laminating 1# belt, 2# belt and 3# belt on the belt laminating drum of the belt laminating drum I station to form a belt composite Part B, the belt fitting drum chassis rotates the belt fitting drum and the belt layer composite part B to the belt fitting drum II station; the belt layer composite part B is in the belt fitting drum II station The steel wire is used for belt winding at the position, and the steel wire wrapped by the belt is guided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com