Expanded end head for anchoring FRP rib, processing method and anchoring method

It is a technology of expanding the end and anchoring, which is applied in the direction of building reinforcements, structural elements, building components, etc. It can solve the problems of difficulty in guaranteeing anchoring performance and limited length of FRP inserted into the node, and achieve the solution of insufficient anchoring length, reliable bonding, The effect of dense bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

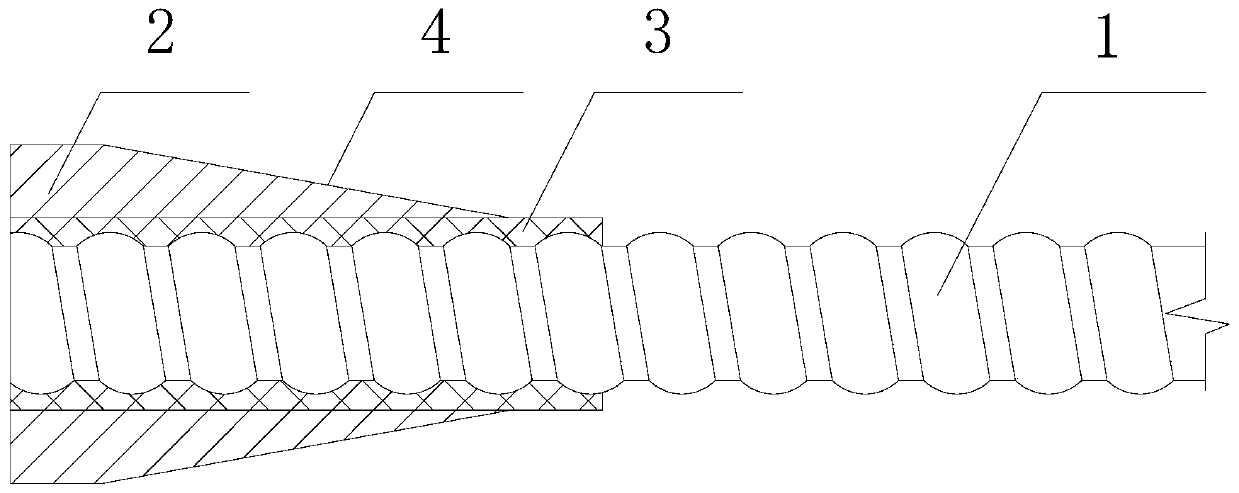

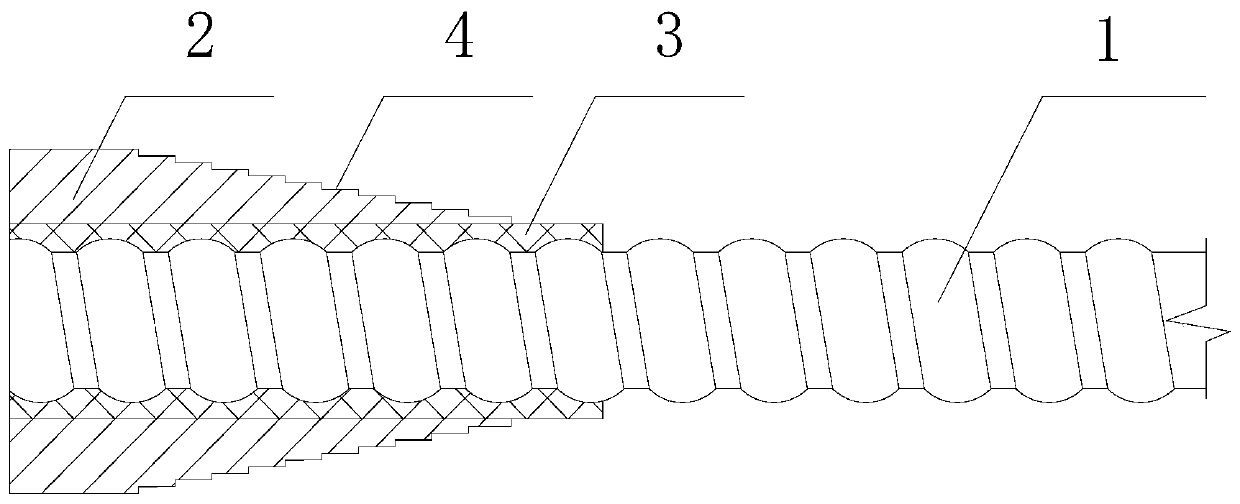

[0057] An enlarged end for FRP tendon anchoring, including an inner layer and an outer layer, the outer layer includes: fiber: 60 parts by mass; thermosetting resin: 40 parts by mass; the inner layer includes: two-way fiber cloth: 40 parts by mass; Thermoplastic resin: 60 parts by mass; fiber is continuous fiber; thermosetting resin is epoxy resin; thermoplastic resin is thermoplastic epoxy resin.

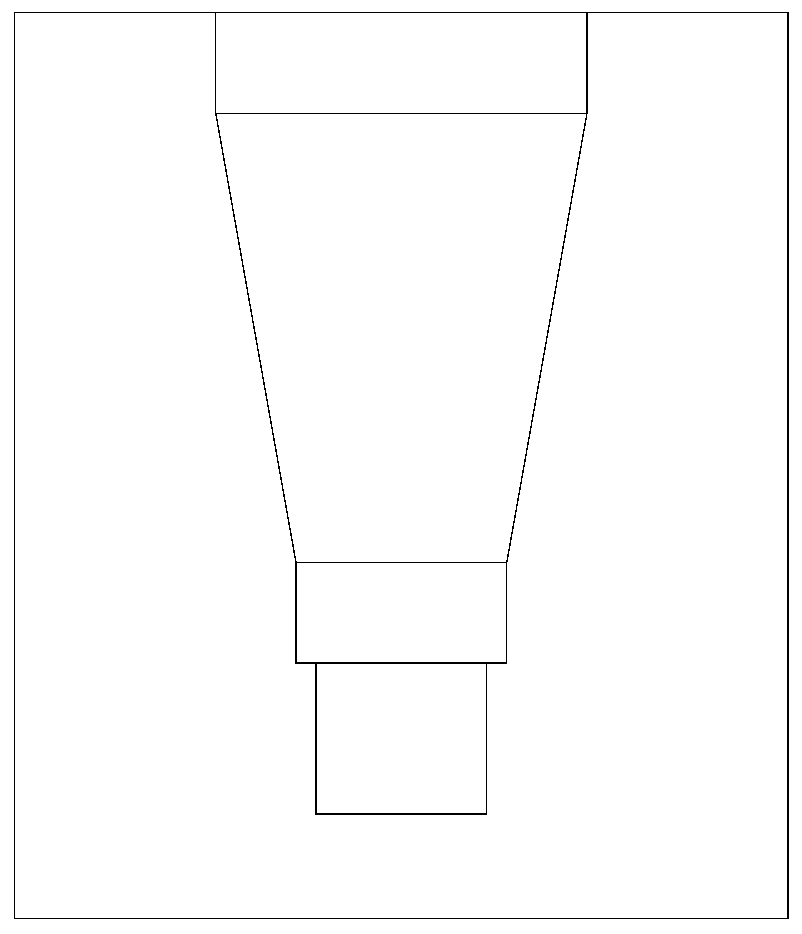

[0058] The expanded end of the FRP tendon anchoring of the present invention is processed by a mold, wherein the mold includes a concave mold with a cavity and a convex film with a mandrel, and the processing method specifically includes:

[0059] Wrap the bidirectional fiber cloth impregnated with thermoplastic resin on the mandrel as the inner layer, and the winding thickness of the inner layer should be 2-5mm higher than the rib height, so as to ensure that the winding layer completely wraps the rib;

[0060] Continue to wind the continuous fiber impregnated with thermosetting r...

Embodiment 2

[0064] An enlarged end for FRP tendon anchoring, including an inner layer and an outer layer, the outer layer includes: fiber: 70 parts by mass; thermosetting resin: 30 parts by mass; the inner layer includes: two-way fiber cloth: 45 parts by mass; Thermoplastic resin: 55 parts by mass; fiber is continuous fiber; thermosetting resin is epoxy resin; thermoplastic resin is thermoplastic epoxy resin.

[0065] The expanded end of the FRP tendon anchoring of the present invention is processed by a mold, wherein the mold includes a concave mold with a cavity and a convex film with a mandrel, and the processing method specifically includes:

[0066] Wind the bidirectional fiber cloth impregnated with thermoplastic resin on the mandrel as the inner layer, and the winding thickness of the inner layer should be 2 to 5 mm higher than the rib height;

[0067] Continue to wind the continuous fiber impregnated with thermosetting resin on the wound two-way fiber cloth as the outer layer. be...

Embodiment 3

[0071] An enlarged end for FRP tendon anchoring, including an inner layer and an outer layer, the outer layer includes: fiber: 65 parts by mass; thermosetting resin: 35 parts by mass; the inner layer includes: two-way fiber cloth: 50 parts by mass; Thermoplastic resin: 50 parts by mass; fiber is continuous fiber; thermosetting resin is epoxy resin; thermoplastic resin is thermoplastic epoxy resin.

[0072] The expanded end of the FRP tendon anchoring of the present invention is processed by a mold, wherein the mold includes a concave mold with a cavity and a convex film with a mandrel, and the processing method specifically includes:

[0073] Wind the bidirectional fiber cloth impregnated with thermoplastic resin on the mandrel as the inner layer, and the winding thickness of the inner layer should be 2 to 5 mm higher than the rib height;

[0074] Continue to wind the continuous fiber impregnated with thermosetting resin on the wound two-way fiber cloth as the outer layer. be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com