Antibacterial flame-retardant decorative fiber board

A board and fiber technology, which is applied in the field of antibacterial and flame-retardant decorative fiber boards, can solve the problems of blending materials that are difficult to achieve good uniformity, increase the dispersion of equipment costs, and limit the wide range of applications, and achieve high hardness and rigidity. , small gap, high impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 prepares modified guar gum

[0034] Disperse 8kg quaternary ammonium salt-16 and 24kg guar gum in 220L distilled water, stir evenly, add 0.32kg BP photoinitiator, irradiate with ultraviolet light for 30min, use Dialysis tube MD44 dialysis bag to dialyze in distilled water, and freeze-dry to obtain Modified guar gum;

[0035] The modified guar gum used in the subsequent preparation of the microcapsules of the present invention is enriched by the preparation method.

Embodiment 2

[0036] Embodiment 2 prepares composite microcapsules

[0037] Disperse the modified guar gum of Example 1 in the aqueous solution to obtain a mixed aqueous solution with a solid content of 4%, stir evenly, heat to 85°C, keep warm for 40min, cool down to 55°C, and make the solid content 3% flame retardant Core (zinc borate, cyclic phosphonate, triphenyl phosphonate mixed in a weight ratio of 1:1:1) aqueous solution is slowly added to the modified guar gum solution, fully stirred, dispersed evenly, cooled to room temperature, filtered , freeze-dried to obtain composite microcapsules;

[0038] The composite microcapsules used in the subsequent examples of the present invention are all enriched by the preparation method of the composite microcapsules in this example.

Embodiment 3

[0039] Example 3 Antibacterial and flame-retardant decorative fiber sheet

[0040] The composition of the mixed material includes: 5% of bleached kraft softwood pulp with a water content of 95%, 60% of chopped polyethylene fibers, 15% of chopped polypropylene fibers, 15% of chopped carbon fibers, and 5% of composite microcapsules;

[0041] The total amount of composite material feeding is 220kg;

[0042] The length of chopped polyethylene fibers is 6mm;

[0043] The length of the chopped polypropylene fiber is 5mm;

[0044] The length of chopped carbon fiber is 6mm;

[0045] Concrete preparation steps are as follows:

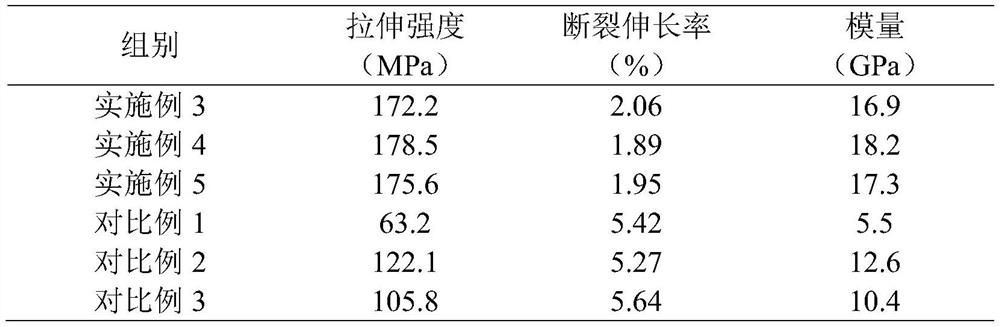

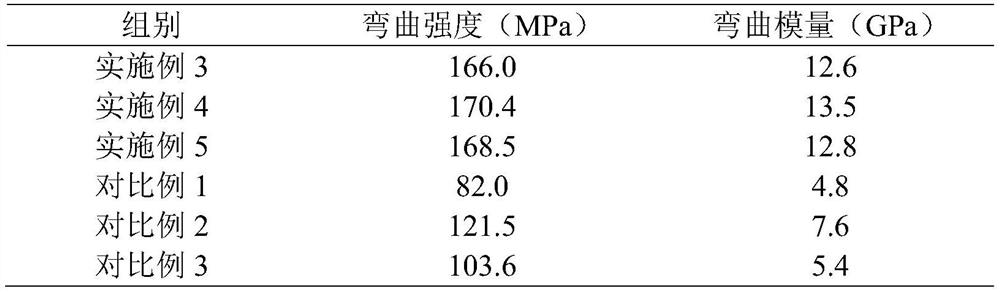

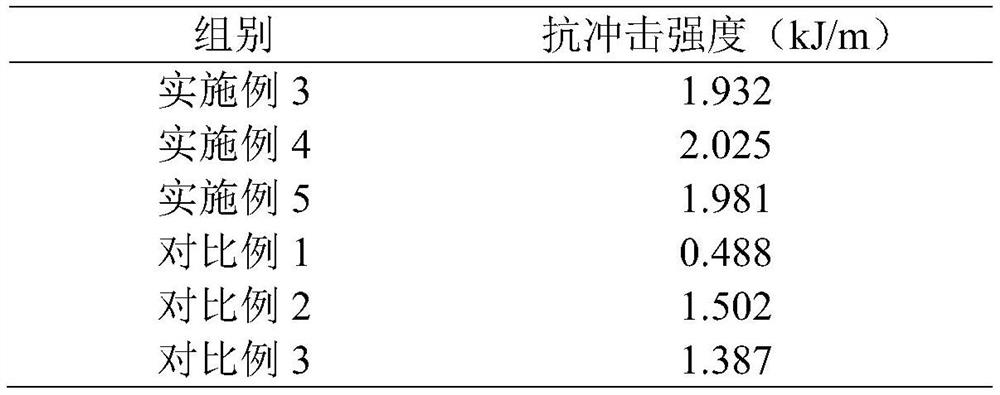

[0046] Disintegrate and refine the bleached kraft softwood pulp in an underwater pulper, then mix it with chopped polyethylene fibers, chopped polypropylene fibers, chopped carbon fibers, and composite microcapsules under the agitator, and pass through the net Forming, pressing water at 20MPa, 50°C for 20s, hot-pressing at 25MPa, 150°C for 60s to obtain a fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com