Compatibilization method of silicon-based thermoplastic elastomer and obtained silicon-based thermoplastic elastomer

A thermoplastic elastomer and thermoplastic resin technology, which is applied in the field of dynamic vulcanization thermoplastic elastomer preparation, can solve the problems of poor compatibility of thermoplastic resins, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] The raw material ratio of silicon-based thermoplastic elastomer is shown in Table 1. Its preparation method is,

[0085] (1) Adding compatibilizer, white carbon black, and hydroxyl silicone oil to methyl vinyl silicone rubber, and pre-mixing in an internal mixer to obtain a mixed rubber;

[0086] (2) physically blending the rubber compound and thermoplastic polyurethane into a melt in an internal mixer at 200°C;

[0087] (3) The molten material is injected into a twin-screw extruder at 180°C, and at the same time, hydrogen-containing silicone oil and a platinum catalyst are added in partitions for dynamic vulcanization, and pelletized to obtain a high-resilience silicon-based thermoplastic elastomer.

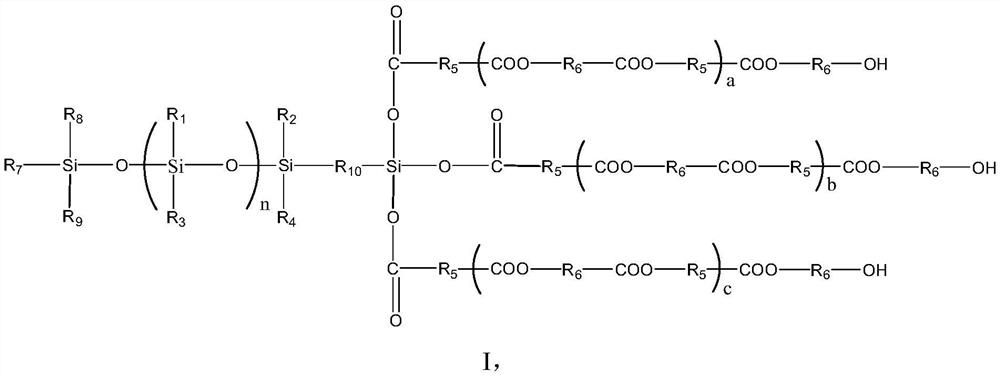

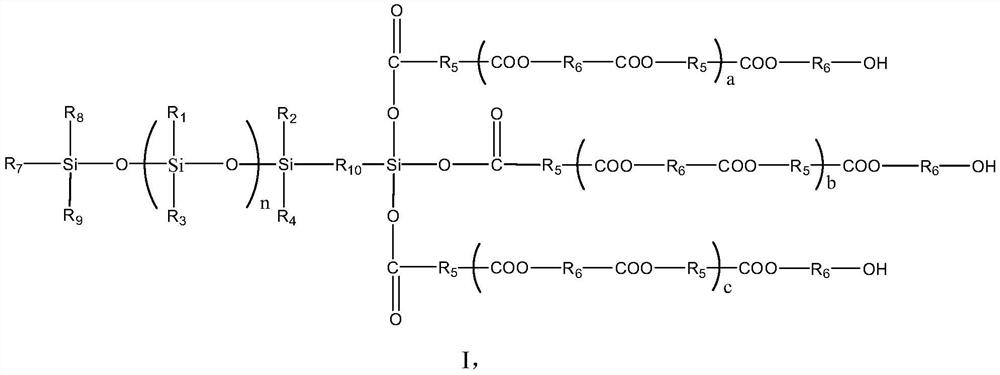

[0088] The compatibilizer is selected as compatibilizer 1, and the structural formula of compatibilizer 1 is shown in Table 3.

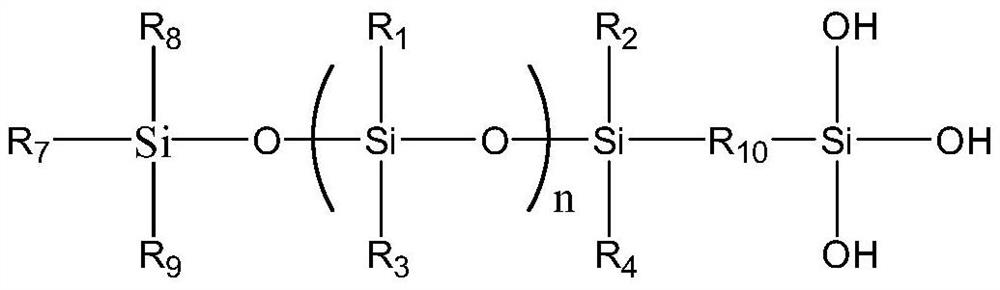

[0089] Compatibilizer 1 is prepared by adding 49.5 g of glutaric acid to 10 g of alkylsiltriol-terminated polysiloxane with a molecular weigh...

Embodiment 2

[0091] The difference between this example and Example 1 lies in that the raw material ratio of the silicon-based thermoplastic elastomer is different, see Table 1 for details. Compatibilizer is with embodiment 1.

Embodiment 3

[0093] The difference between this example and Example 1 lies in that the raw material ratio of the silicon-based thermoplastic elastomer is different, see Table 1 for details. Compatibilizer is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com