Constant-thrust rocket engine or engine thrust chamber performance testing device

A rocket engine and test device technology, which is applied to rocket engine devices, jet propulsion devices, machines/engines, etc., can solve problems such as the inability to perform fluid flow performance tests with back pressure, and achieve stable pressure and convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

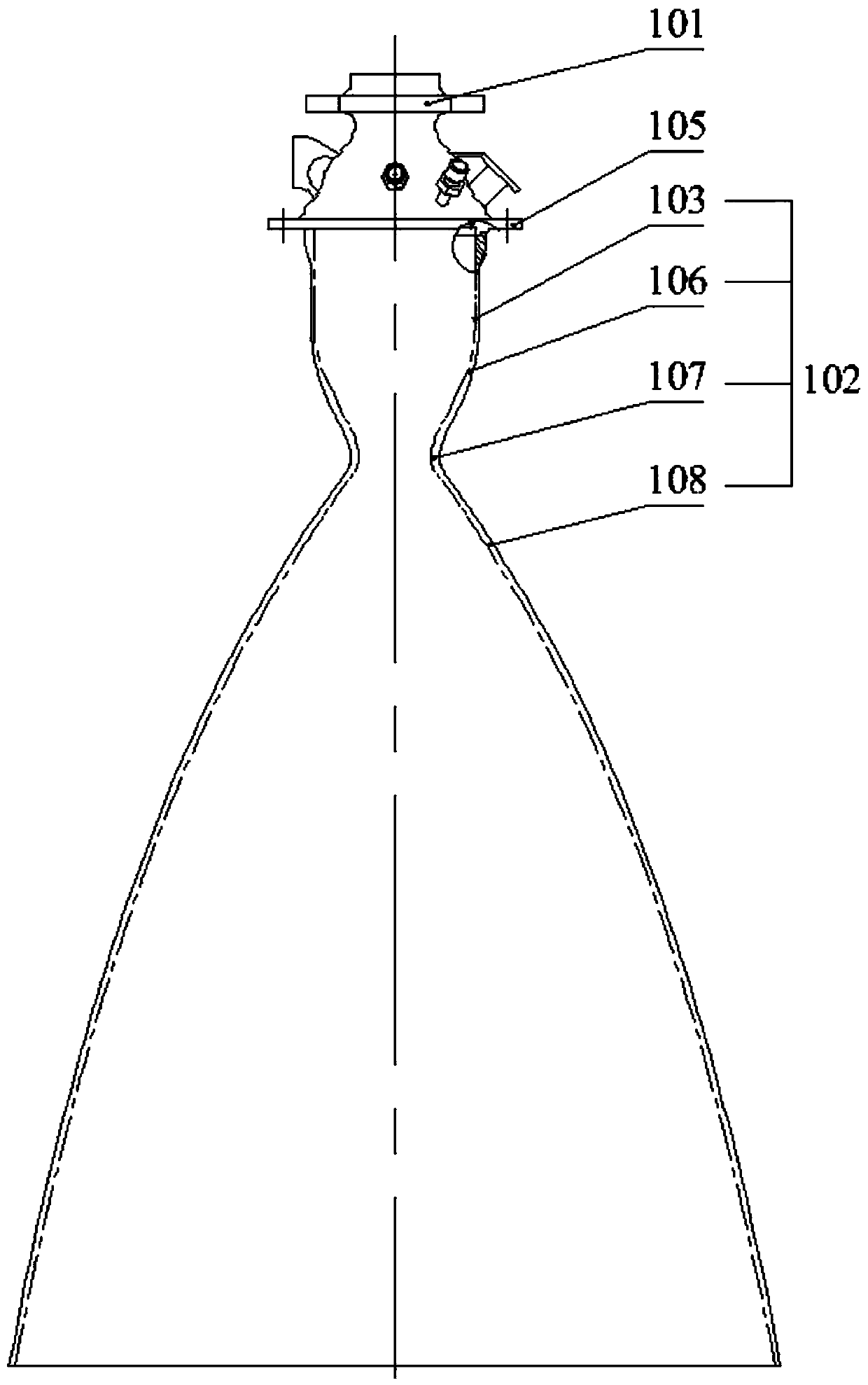

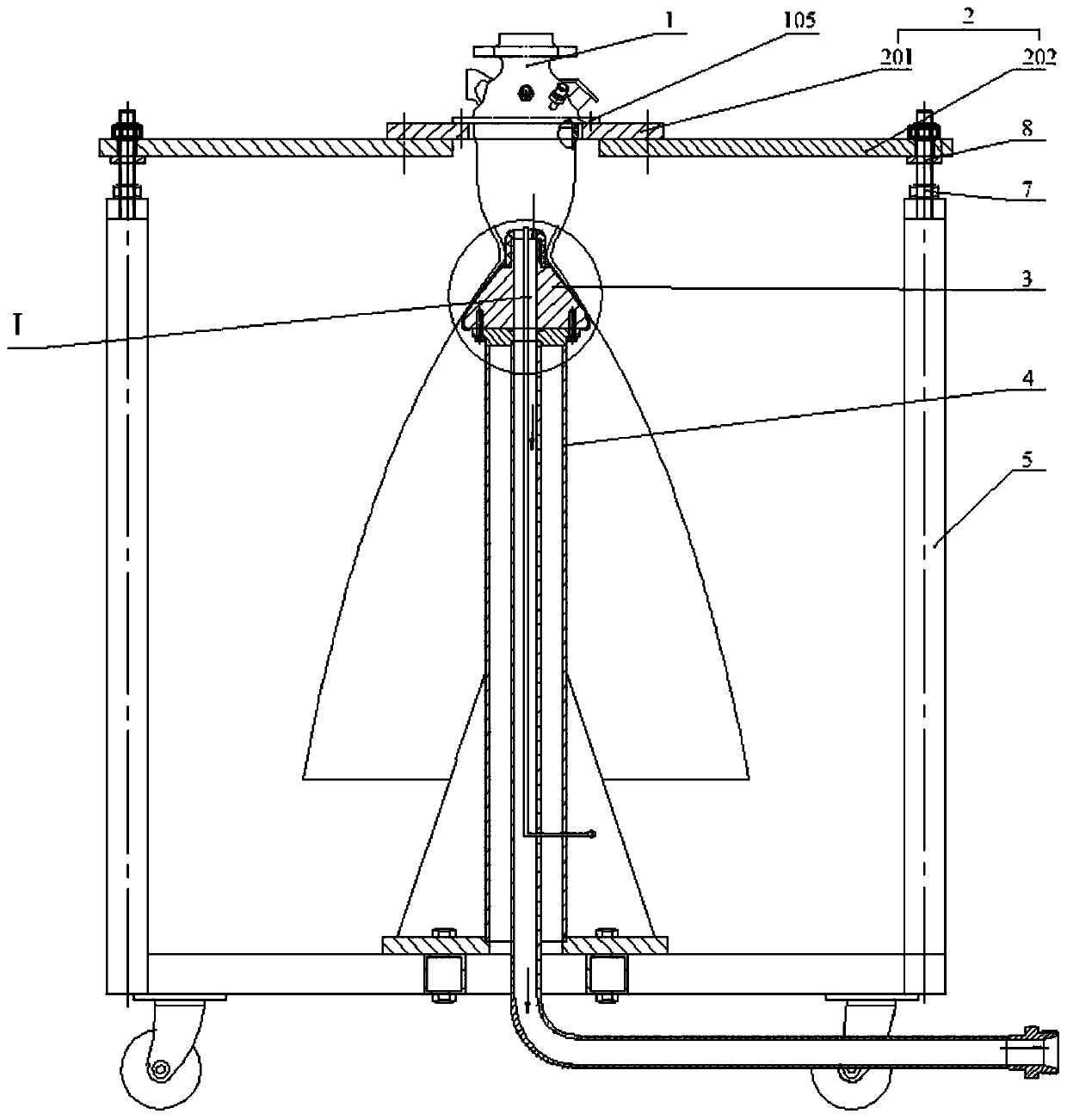

[0045] refer to figure 2 , a fixed-thrust rocket engine or engine thrust chamber performance testing device, comprising an anti-top assembly 2, a throat support assembly 3, a bottom support assembly 4 and a stand 5.

[0046] The thrust chamber 1 of the engine under test is fixedly connected in the stand 5 through the anti-top assembly 2 . Throat 107 and expansion section 108 of engine thrust chamber 1 support throat support assembly 3 , the bottom of throat support assembly 3 is provided with bottom support assembly 4 , and bottom support assembly 4 is fixedly connected to the bottom surface of stand 5 .

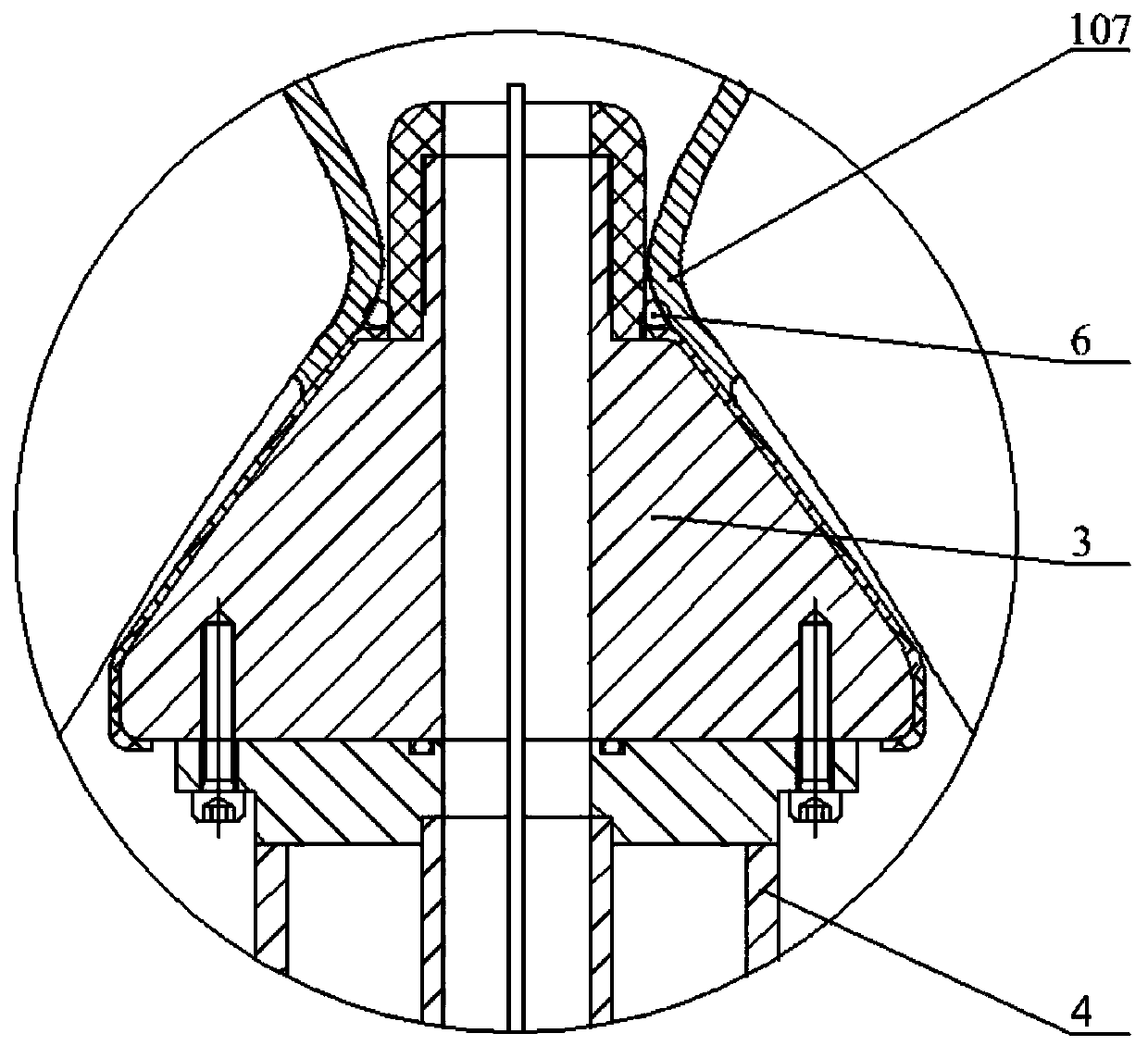

[0047] refer to image 3 and Figure 4 , The throat support assembly 3 includes a rubber head cover 301 , a rubber protective cover 302 and a core 303 . Considering the weight of the engine thrust chamber 1 and the pressure during the test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com