Wind indicator zero calibration method of wind generating set

A technology for wind turbines and wind turbines, which is used in the testing/calibration of speed/acceleration/impact measurement equipment, measurement devices, instruments, etc., and can solve the problem of increased labor costs, random errors, and offset of the zero position of the wind vane and the axis of the nacelle, etc. problems, to achieve the effect of improving power generation efficiency, reducing work tasks, and reducing operation and maintenance risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

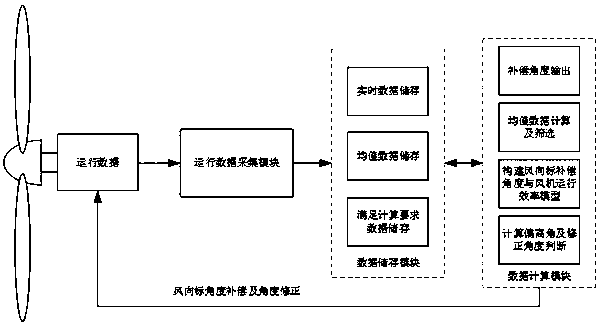

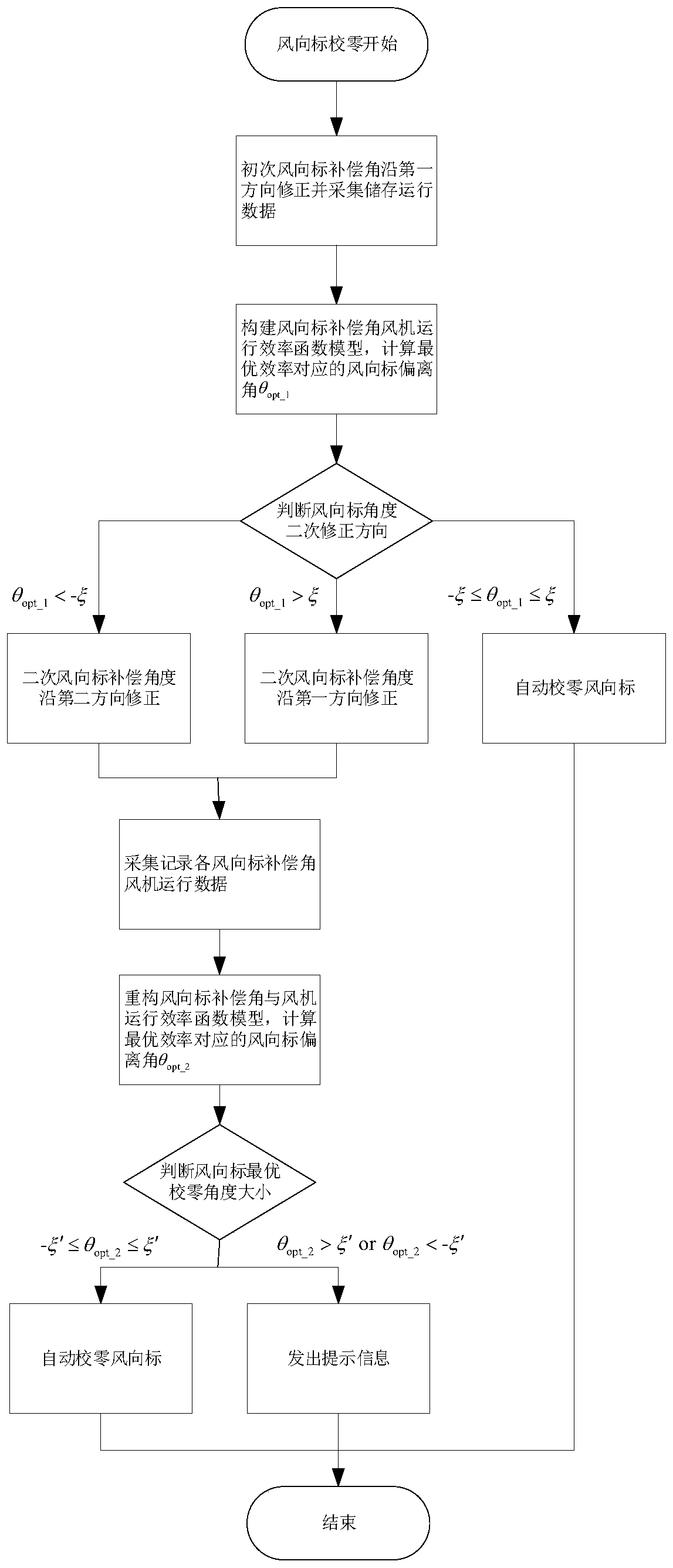

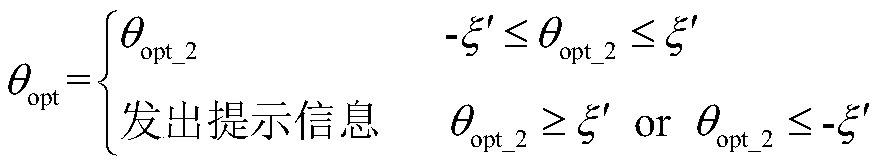

[0039] Such as figure 1 Shown, the present invention comprises the steps:

[0040] 1) According to the specified time period T 1 Execute the zero calibration task of wind direction regularly or at a specified time; when the wind turbine unit executes the zero calibration task of wind direction calibration, the wind turbine unit enters the zero calibration mode of wind direction calibration and starts zero calibration of wind direction calibration.

[0041] 2) Adjust the wind vane angle compensation, collect and record the fan operation data, the specific operation is as follows:

[0042] 2.1) Set the wind turbine vane compensation angle to 0°;

[0043] 2.2) The operation data collection module collects the real-time operation data of the fan according to the given data collection period and records them in the data storage module. The collection period is T 2 for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com