Material shortage warning method

A material shortage and material technology, applied in the field of SMT production, can solve problems such as lack of output rate, yield fluctuation, lack of process stability, unfavorable production efficiency improvement and quality management, and reduction of production line operation efficiency, so as to reduce the labor intensity of workers, It is convenient to quickly take materials and improve the effect of production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

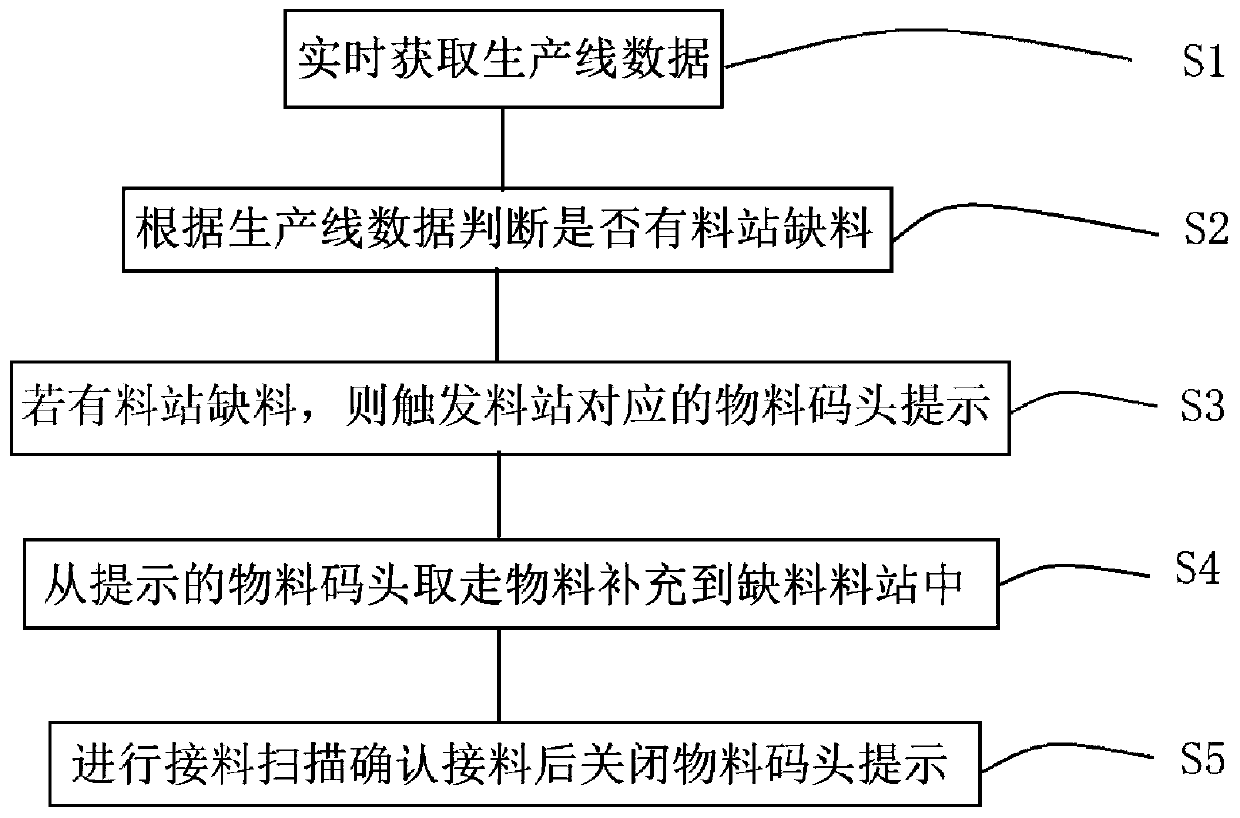

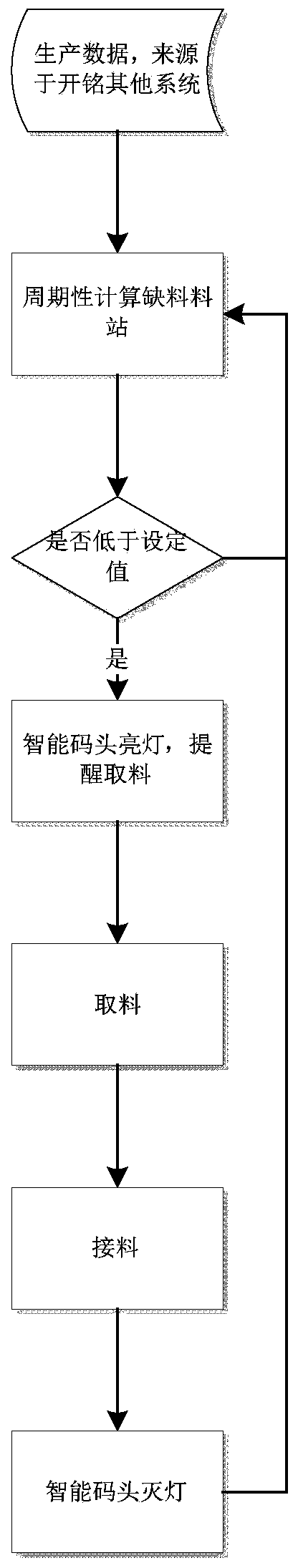

[0035] Such as figure 1 with image 3 Shown, a kind of material shortage early warning method is applied to SMT production line, and described material shortage early warning method comprises:

[0036] Step S1: Obtain production line data in real time;

[0037] Real-time access to the data of the SMT production line being produced, especially the quantity of materials at each material station.

[0038] Step S2: According to the data of the production line, it is judged whether there is a material shortage at the material station;

[0039] According to the production speed of the production line and the material consumption speed of each material station, set a safer material threshold value of the material station, allowing the operator to not cause the material station to be consumed during the replenishment time, and then the production line stops; according to the actual situation According to the application situation, the set material threshold of the material station ...

Embodiment 2

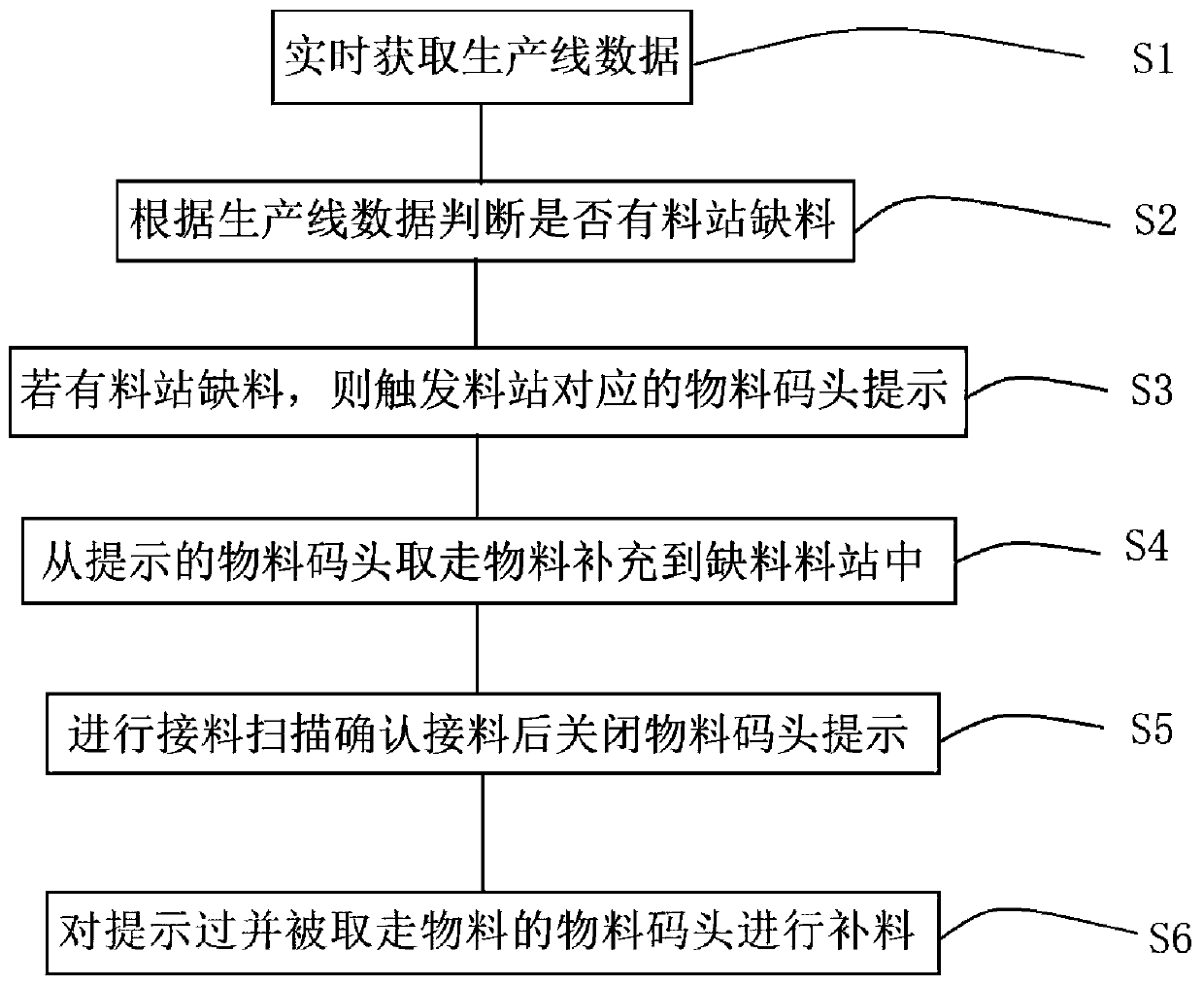

[0054] Such as figure 2 with image 3 Shown, a kind of material shortage early warning method is applied to SMT production line, and described material shortage early warning method comprises:

[0055] Step S1: Obtain production line data in real time;

[0056] Real-time access to the data of the SMT production line being produced, especially the quantity of materials at each material station.

[0057]Step S2: According to the data of the production line, it is judged whether there is a material shortage at the material station;

[0058] According to the production speed of the production line and the material consumption speed of each material station, set a safer material threshold value of the material station, allowing the operator to not cause the material station to be consumed during the replenishment time, and then the production line stops; according to the actual situation According to the application situation, the set material threshold of the material station ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com