Secure chip mounter applied to circuit board processing

A circuit board and patch technology, which is applied in the field of patch equipment for circuit board processing, can solve the problems of unable to hold the suction nozzle and drop off of the suction nozzle, and achieve the effects of improving sliding efficiency, preventing falling off, and reducing replacement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

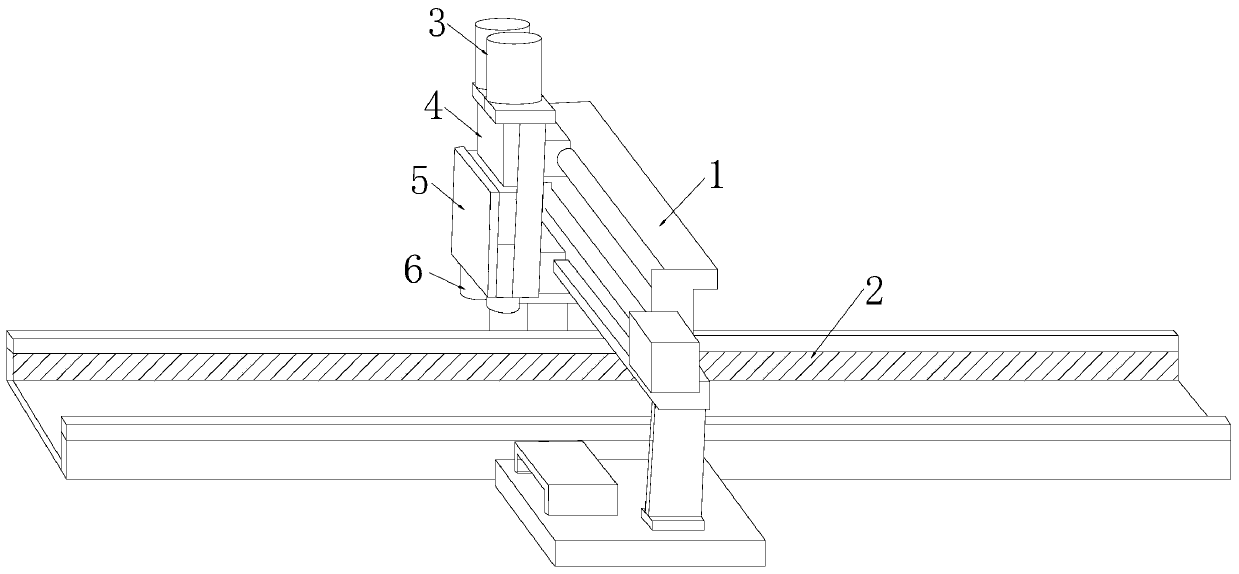

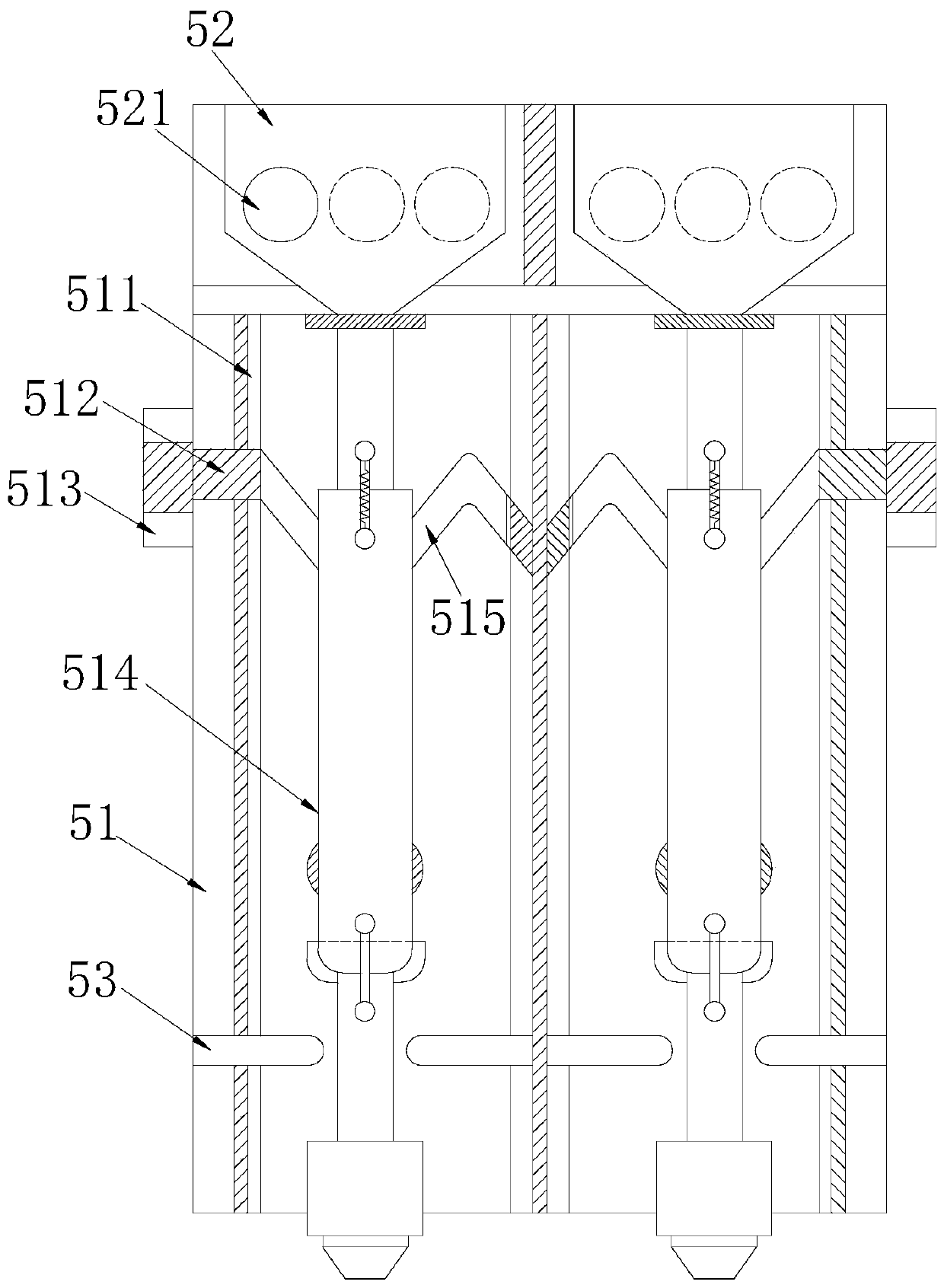

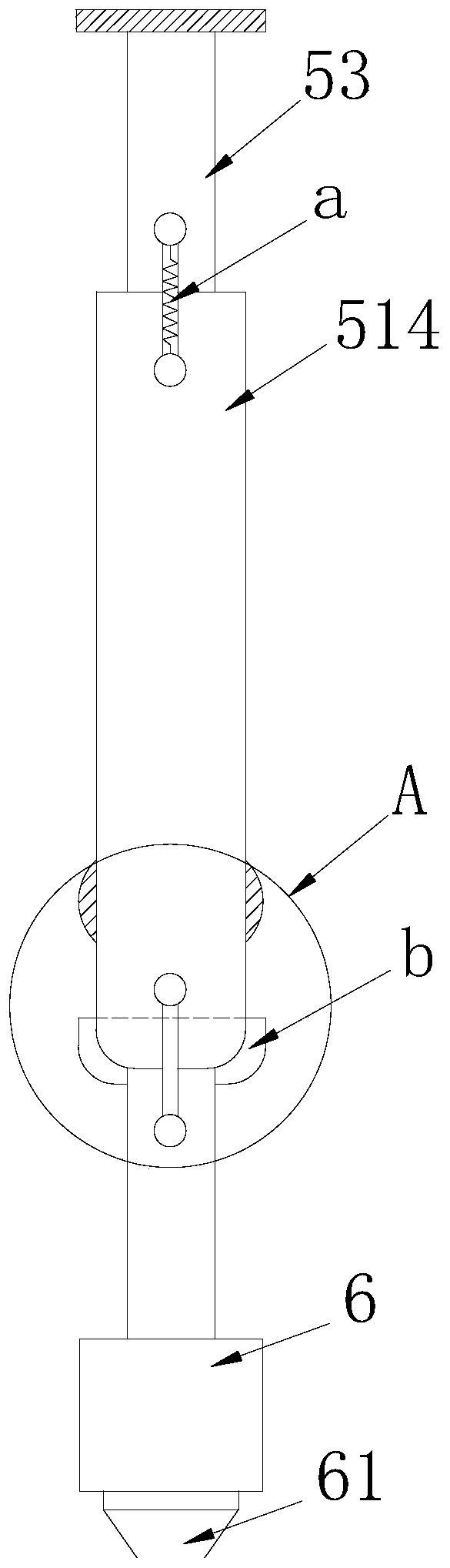

[0027] Such as Figure 1-Figure 7 As shown, the present invention provides a safe circuit board processing SMT equipment, its structure includes a horizontal guide rail 1, a transfer slot 2, a lifting motor 3, a longitudinal guide rail 4, a support table 5, a placement head 6, the transfer slot 2. A feeder is installed inside, and the circuit board is clamped horizontally in the conveying groove 2. The horizontal guide rail 1 and the longitudinal guide rail 4 are mechanically connected and movably matched. The bottom end of the longitudinal guide rail 4 is equipped with a support platform 5. The bottom of the table 5 is provided with a patch head 6, the signal output end of the longitudinal guide rail 4 is electrically connected to the lifting motor 3, and a support platform for fixing the horizontal guide rail 1 is provided on the left and right outer sides of the transmission slot 2, and the horizontal guide rail 1 is Door-shaped structure, the inside of the patch head 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com