Polishing composition, method for producing same, and polishing method using polishing composition

A composition and compound technology, used in polishing compositions containing abrasives, grinding machine tools, manufacturing tools, etc., can solve the problems of reduced flatness of silicon wafers, and the metamorphic layer is not easy to be ground, and achieves the effect of eliminating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

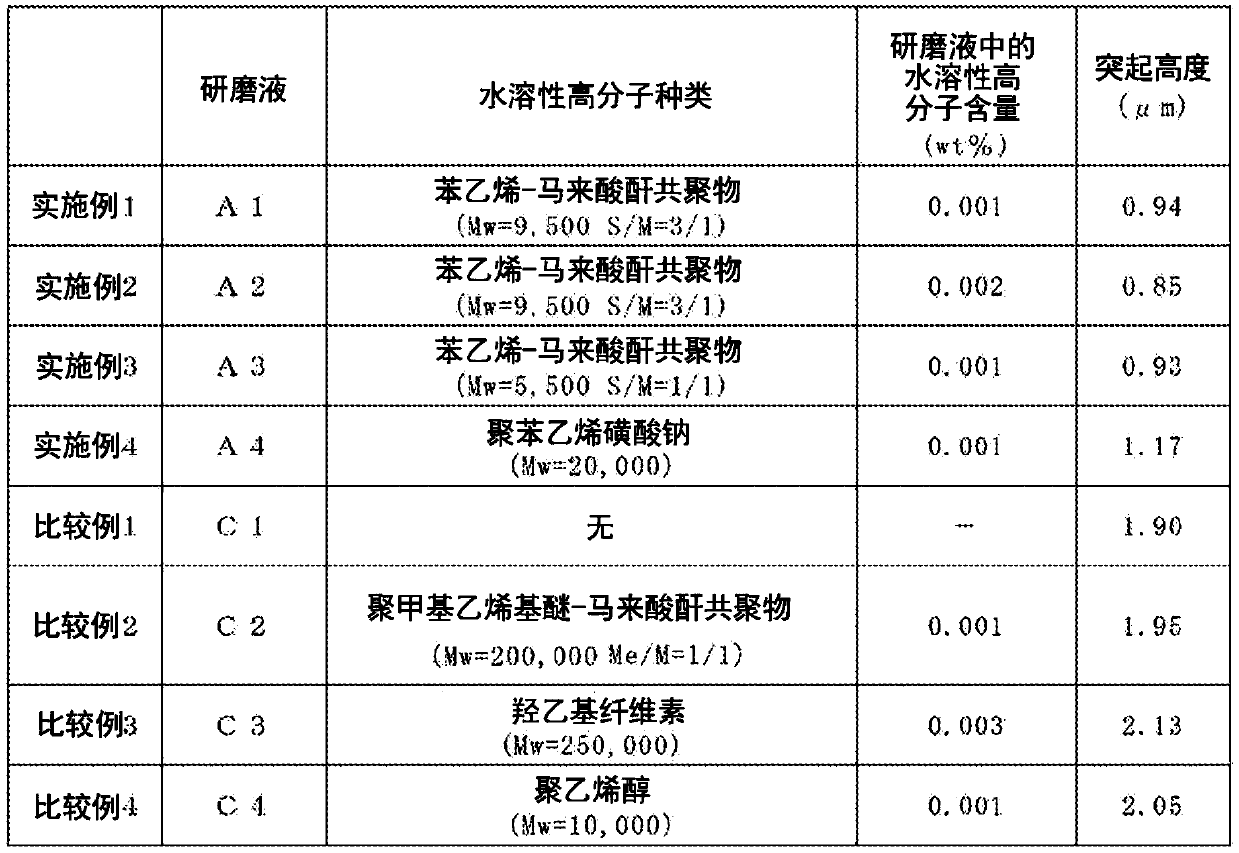

[0078] The present invention will be described in more detail using the following examples and comparative examples. However, the scope of protection of the present invention should not be limited only to the following examples. In addition, "%" and "part" represent "mass%" and "mass part", respectively, unless there is special mention. In addition, in the following examples, unless otherwise specified, the operation was carried out under the conditions of room temperature (25° C.) / relative humidity 40 to 50% RH.

[0079]

[0080] (Polishing composition A1)

[0081] With the content of colloidal silica (average primary particle diameter 55nm) being 9% by mass, potassium carbonate (K 2 CO 3 ) content of 1.7% by mass, tetramethylammonium hydroxide (TMAH) content of 2.5% by mass, ethylenediaminetetra(methylenephosphonic acid) (EDTPO) content of 0.1% by mass, styrene-malay Acid anhydride copolymer (weight-average molecular weight: 9500, styrene / maleic anhydride (S / M) = 3 / 1) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com