Combined type bus fire extinguishing bag

A bus and foam technology, applied in fire rescue and other directions, can solve the problems of less configuration of fire extinguishers, inability to effectively extinguish fire, on-site chaos, etc., to achieve the effect of low cost, automatic detection and judgment, convenient replacement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Provide the specific embodiment of the present invention below and illustrate with accompanying drawing.

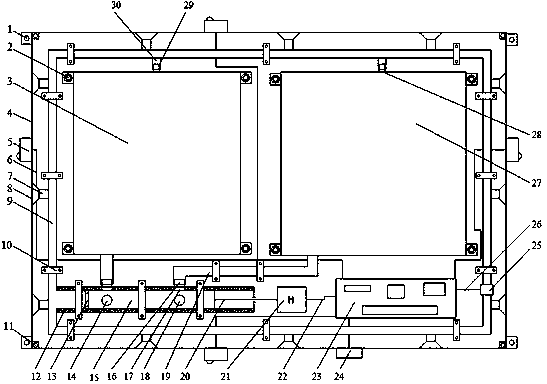

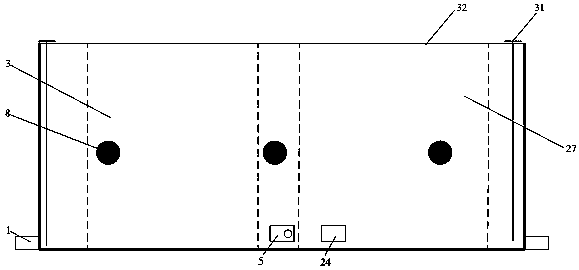

[0010] figure 1 The middle annular pipeline 9 and the liquid mixing cylinder 15 are installed on the box body 4 through the fixing clip 10 to form an internally connected pipeline system. A kind of foam generation solution is housed in the reactant container 3, another kind of reaction solution is housed in the reactant container 27, and each reactant container pipeline is connected with the joint 16 on the mixed liquid cylinder 15 with a pipe joint, and the reactant container 27 is connected to the mixed liquid cylinder 15. When the connecting pipe 19 is longer, the fixed clip 10 can be used to fix the pipeline on the casing 4, and the afterbody of each reactant container communicates with the annular pipeline with a joint 29 and a connecting pipe 30, and a sealing plastic film paper 28 is housed on the joint 29. Each reactant container is fixed on the box body 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com