Embedded accompanying tool bridge for automobile aluminum alloy frame

An aluminum alloy and built-in technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems that cannot be recycled repeatedly, destroy the structure of the beam body, and the fixture cannot follow, etc., to achieve light weight, small size, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

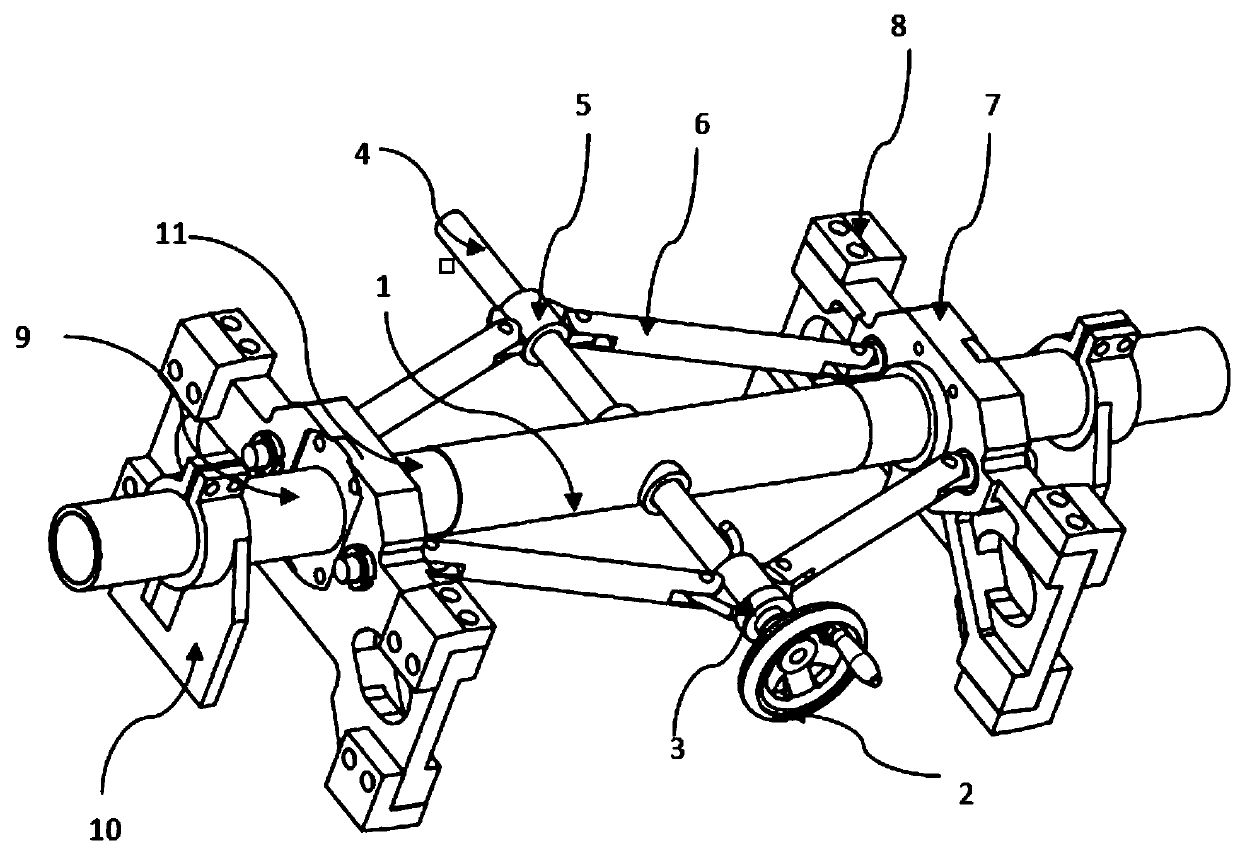

[0027] like figure 1 Shown is the basic structure of an embodiment, including a main frame 1, an outer limit plate 10, and a screw clamping and positioning mechanism. The screw clamping and positioning mechanism includes a screw 4, a connecting rod 6 and a movable base plate 7, The screw mandrel 4 passes through the through hole arranged in the middle of the main frame 1, and is vertically installed in the main frame 1. The screw rod 4 is respectively set with a screw nut hinge seat 5 on both sides of the main frame 1. The two sides of the nut hinge seat 5 are respectively hinged connecting rods 6, the movable base plate 7 is set on the main frame 1 and is slidably connected with the main frame 1, and the other end of the connecting rod 6 is hinged with the movable base plate 7, The outer limiting plate 10 is fixedly fitted on both ends of the main frame 1 and installed on the outside of the movable base plate 7 .

[0028] Optimizing on the basis of the above-mentioned embodi...

Embodiment 2

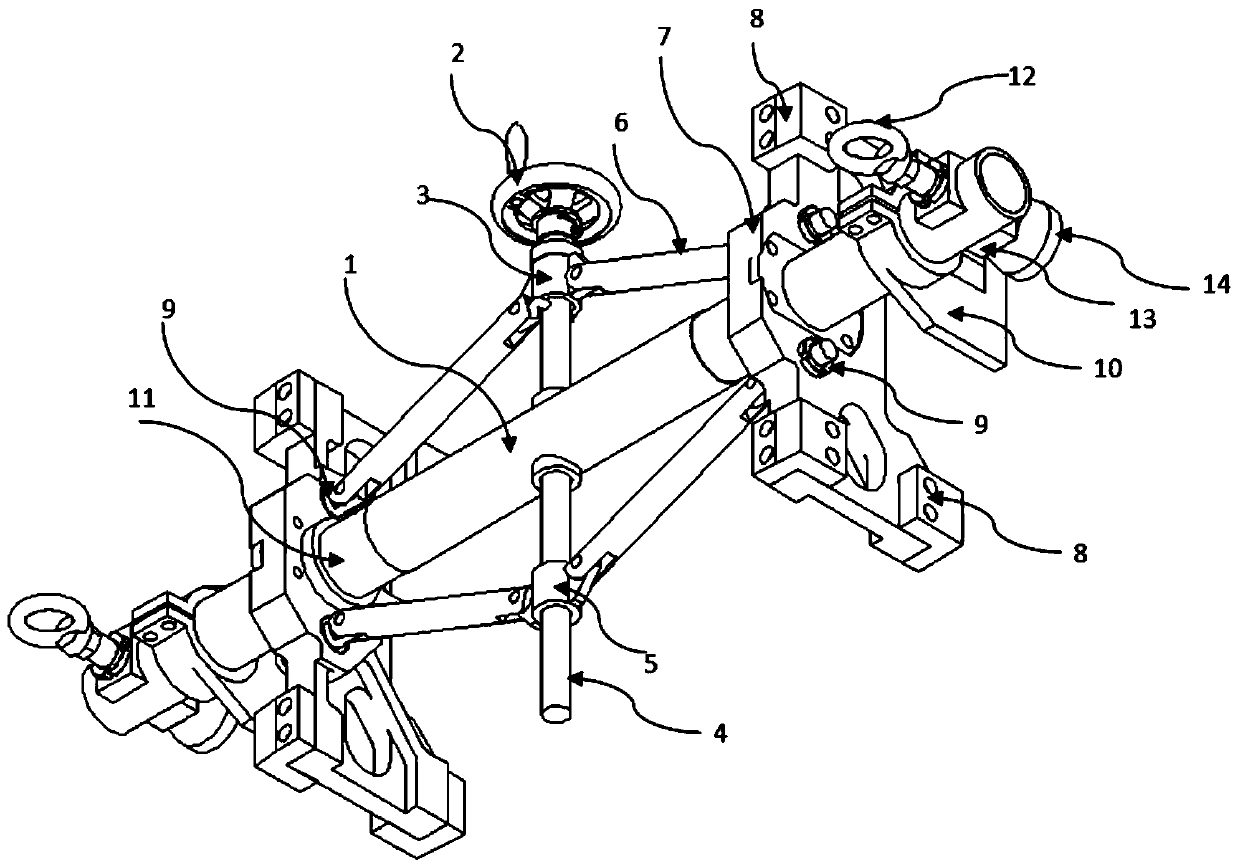

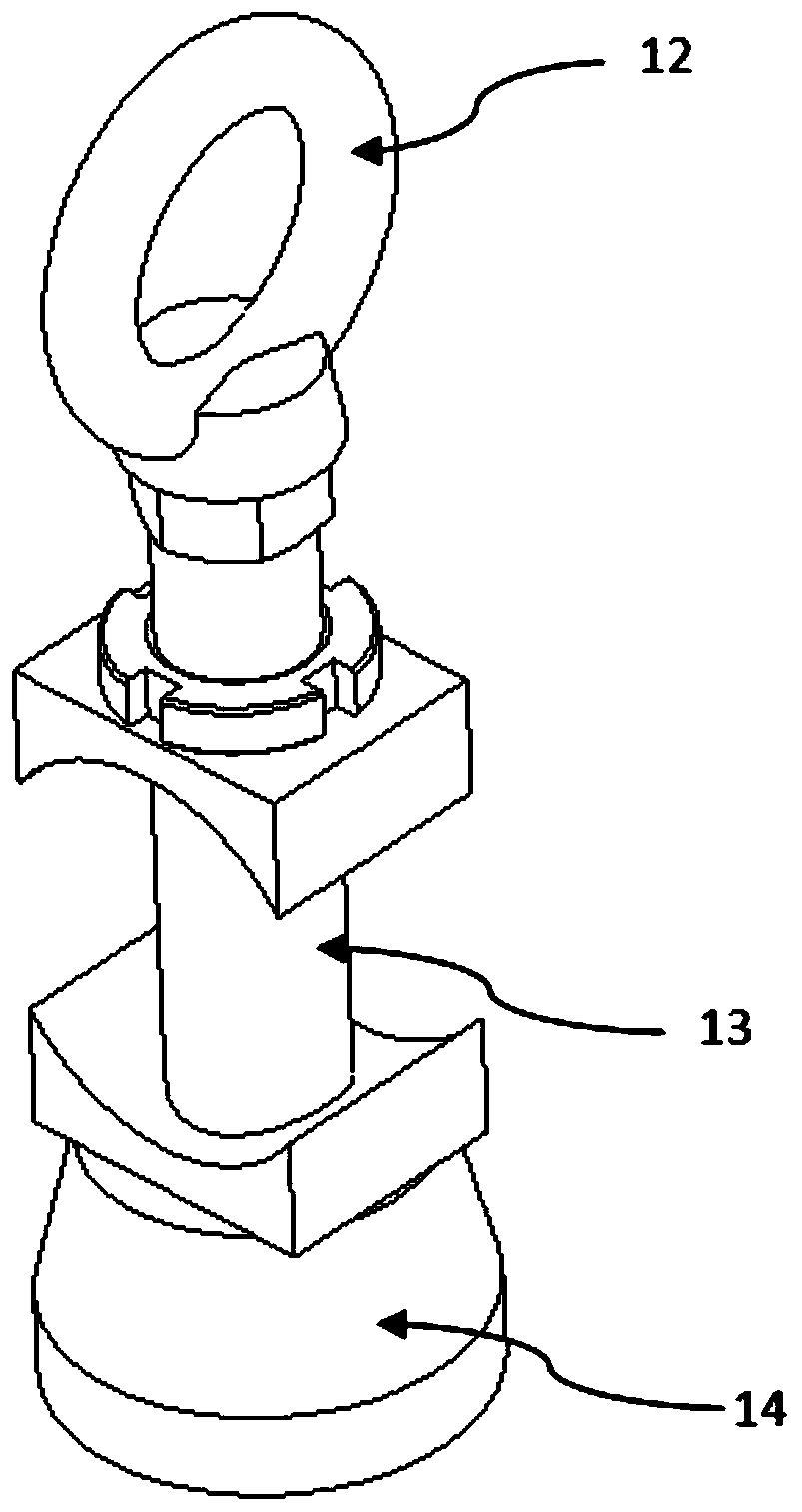

[0035] Example 2 is a further optimized solution based on Example 1. The difference between the technical solution provided by Example 2 and Example 1 is that on the basis of Example 1, the end of the main frame 1 is fixed to two Secondary positioning devices, such as figure 2 and image 3 As shown, the secondary positioning device includes an eye screw 12 at the top, a connecting rod 13 in the middle and a conical head cap 14 at the bottom. The connecting rod 13 penetrates through the main frame 1 and is fixedly connected with the main frame 1. 12 is threadedly connected with the connecting rod 13 and installed above the main frame 1, the conical plug cap 14 is fixed on the lower end of the connecting rod 13, the inside of the conical plug cap 14 is a tapered hole, the The conical plug cap 14 can be assembled and fixed with the conical plug.

[0036] The specific working process is: the figure shows the clamping and positioning mechanism of the screw rod, adjust the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com