Polishing machine for water pump manufacturing and mating dust sucking and preventing mechanism thereof

A technology of polishing machine and water pump, which is applied in the direction of manufacturing tools, grinding machine parts, grinding/polishing equipment, etc., and can solve the problems of inconvenient installation, fixed adjustment, secondary pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

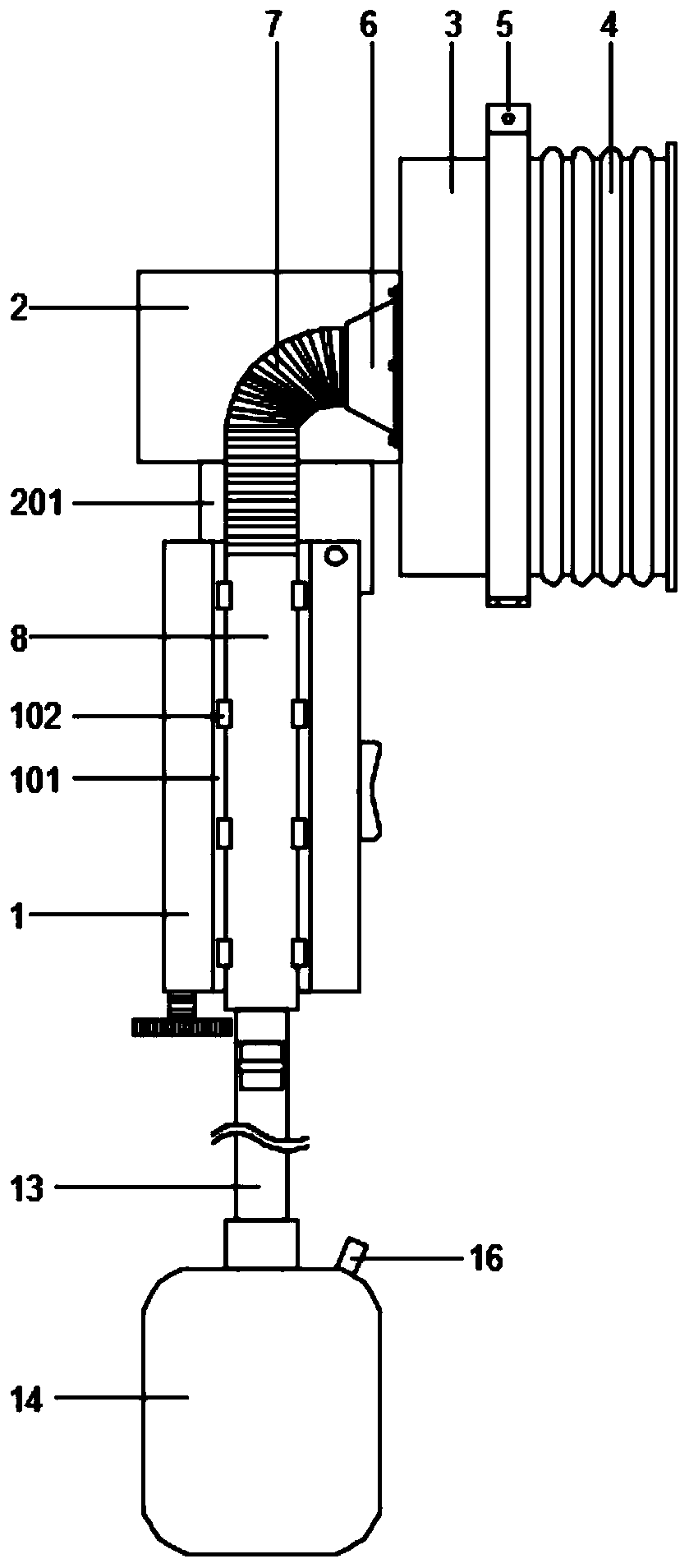

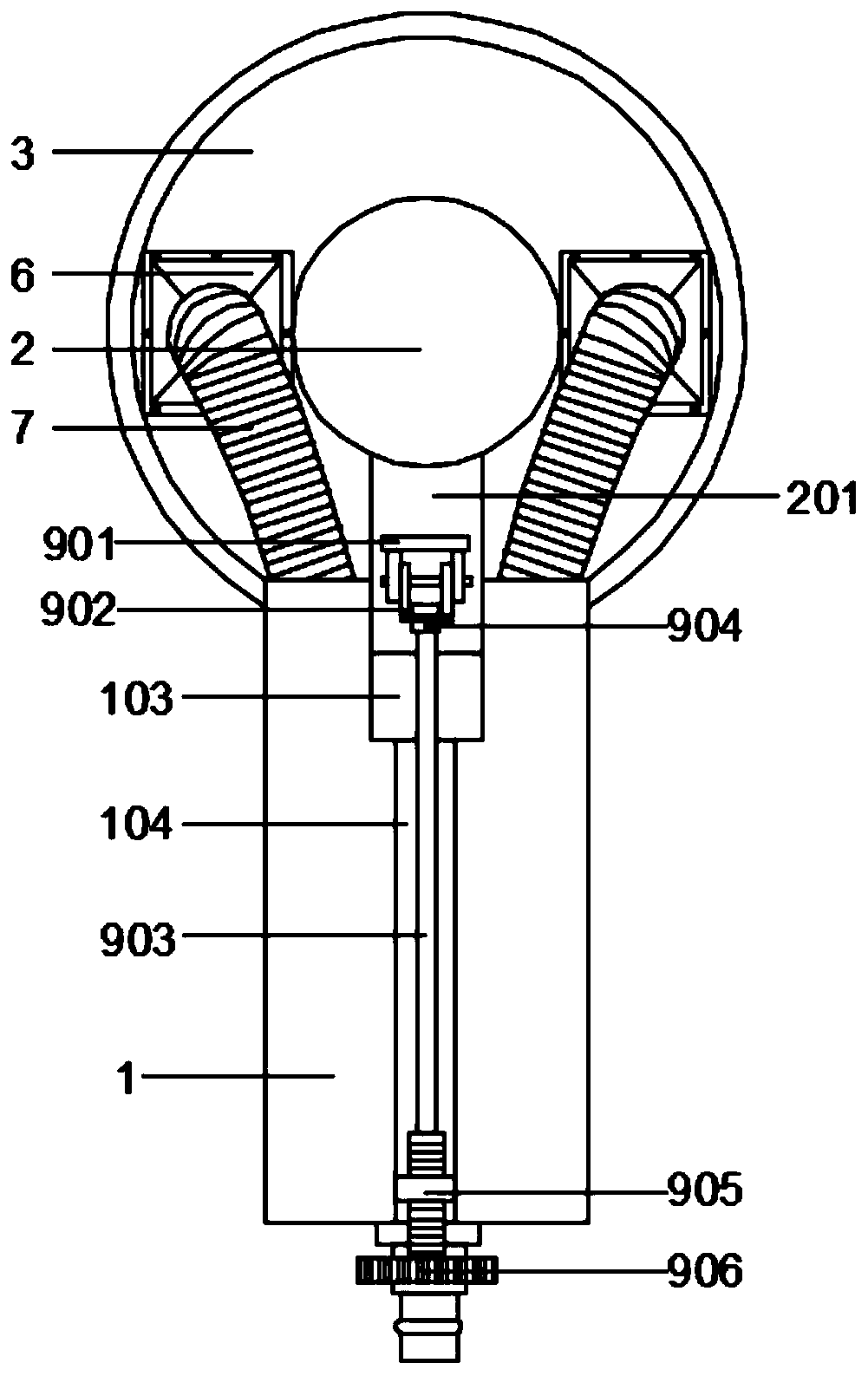

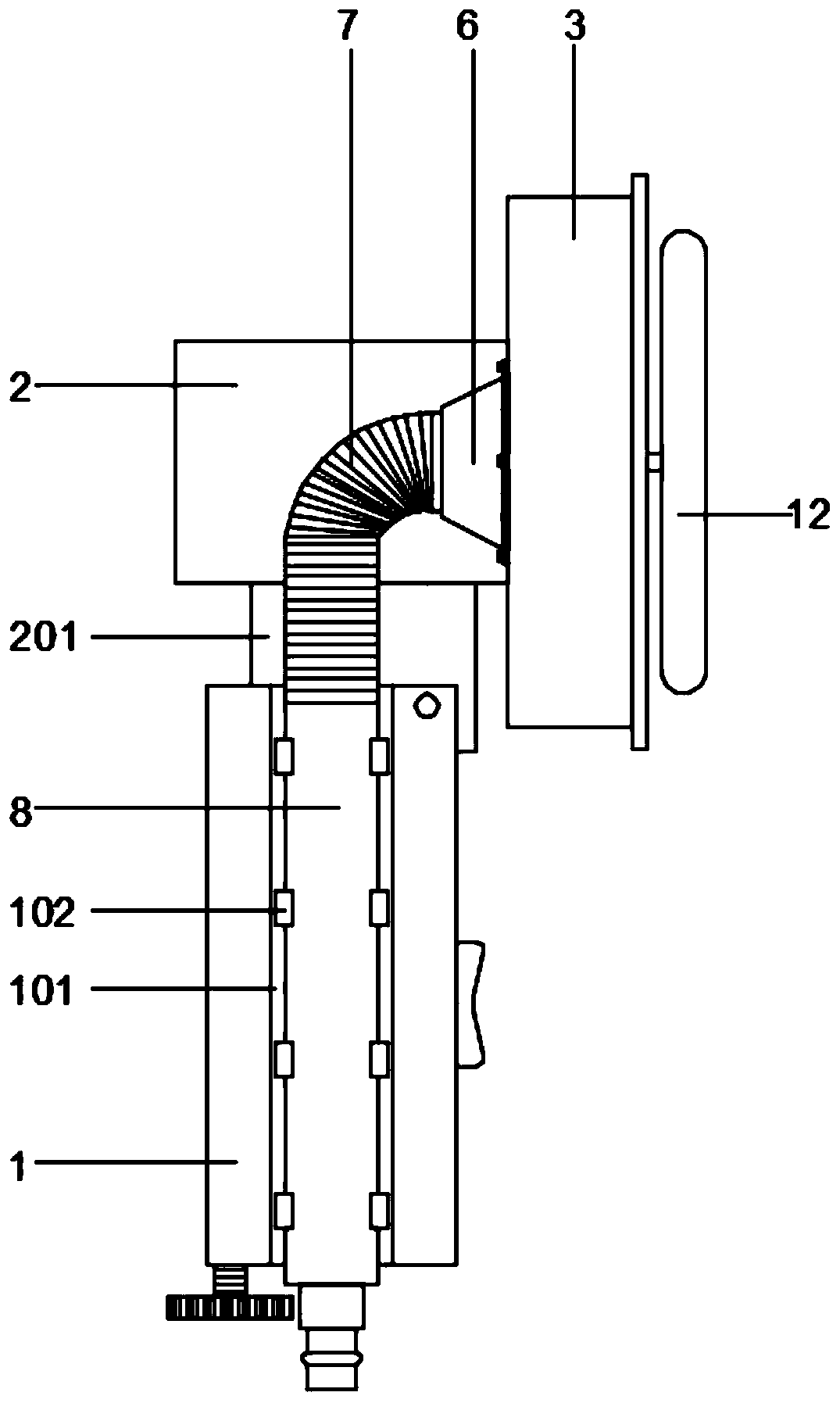

[0036] as attached figure 1 to attach Figure 8 Shown:

[0037]The present invention provides a grinder for water pump manufacture and its supporting dust-proof mechanism, including: a handle body 1, a rectangular groove A101, a clamp A102, a rectangular groove B103, a rectangular groove C104, a motor assembly 2, a rectangular plate 201, and a protective cover 3. Dustproof cover 4, filter hole 401, clamp B5, funnel-shaped connecting cover 6, metal hose 7, cylindrical tube 8, adjustment mechanism 9, rotating connecting seat A901, rotating connecting seat B902, cylindrical rod 903, iron stopper 904, rectangular iron 905, bolt 906, fan blade 10, filter plate 11, filter hole 1101, grinding wheel 12, connecting pipe 13, collection bucket 14, partition 15, circular hole 1501 and air outlet pipe 16; the front surface of the handle main body 1 A rectangular groove A101 is opened, and four clamps A102 are arranged in the rectangular groove A101; a rectangular groove C104 is opened on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com