A kind of preparation method of potassium hydroxide

A potassium hydroxide, hydroxide technology, applied in the directions of alkali metal hydroxides, chemical instruments and methods, chemical/physical processes, etc., can solve the problems such as long time consumption and low efficiency of potassium hydroxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

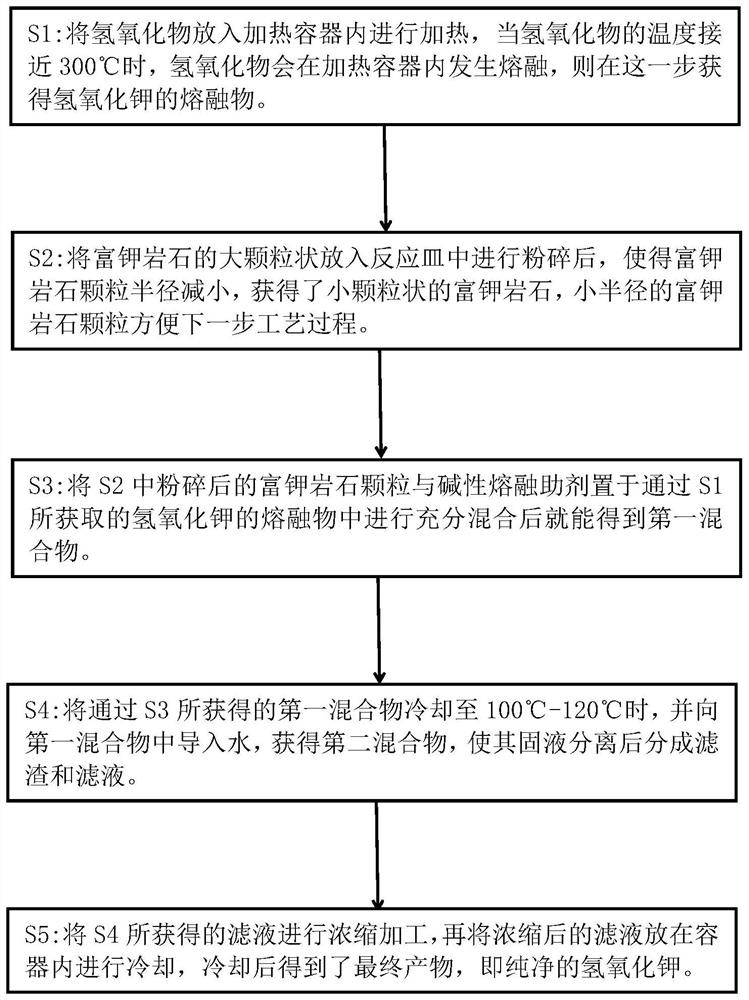

[0028] Such as Figure 1 to Figure 5 Shown, the preparation method of a kind of potassium hydroxide of the present invention, this preparation method comprises the following steps:

[0029] S1: Put the hydroxide into the heating container and heat it. When the temperature of the hydroxide is close to 300° C., the hydroxide will melt in the heating container, and then obtain the melt of potassium hydroxide in this step;

[0030] S2: After putting the large particles of potassium-rich rock into the reaction vessel for crushing, the radius of potassium-rich rock particles is reduced, and small-sized potassium-rich rocks are obtained, which are convenient for the next process ;

[0031] S3: the potassium-rich rock particles pulverized in S2 and the basic melting aid are placed in the molten potassium hydroxide obtained through S1 and fully mixed to obtain the first mixture;

[0032] S4: cooling the first mixture obtained through S3 to 100°C-120°C, and introducing water into the ...

Embodiment approach

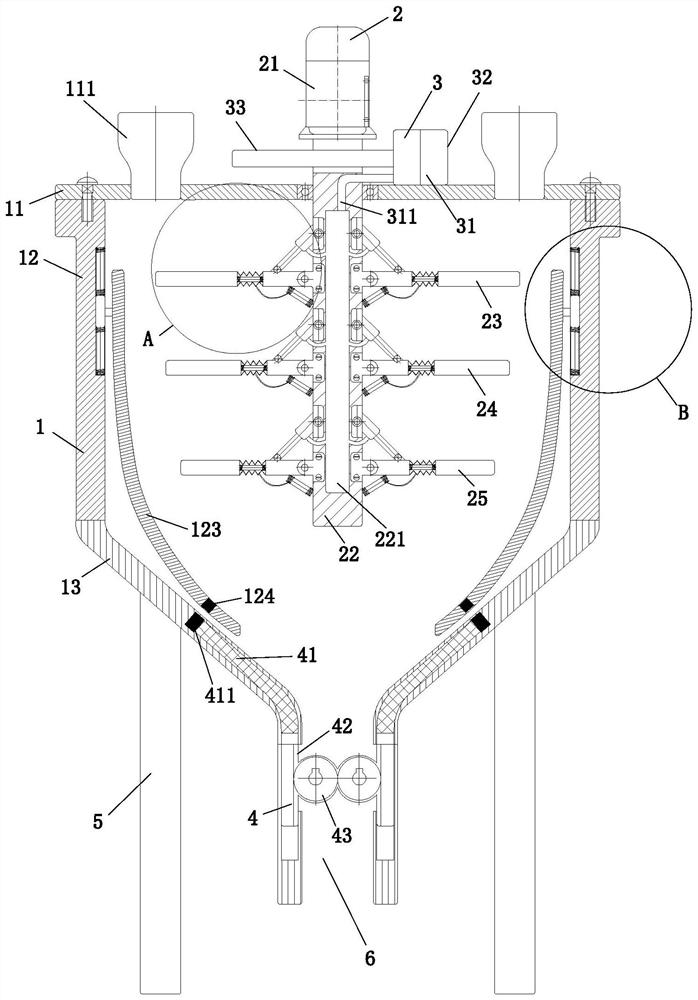

[0035] As an embodiment of the present invention, the rotating shaft 22 is provided with a hollow chamber 221, and the end cover 11 is provided with an air supply device 3, which includes an air bag 31, a cam 33, and a baffle. 32. The air bag 31 is fixedly connected to the end cover 11, and one end is fixedly connected to the baffle plate 32. The cam 33 is sleeved on the outer ring of the output shaft of the motor 21; the No. 1 crushing plate 23 and the No. 2 crushing plate The plate 24 and the No. 3 crushing plate 25 are all hinged on the outside of the rotating shaft 22. The outer wall of the rotating shaft 22 is close to the No. 1 crushing plate 23, the No. 2 crushing plate 24, and the No. 3 crushing plate 25. The other end of the cylinder 222 is respectively hinged with the No. 1 crushing plate 23, the No. 2 crushing plate 24, and the No. 3 crushing plate 25; during operation, the cam 33 rotates with the rotation of the output shaft of the motor 21, and the airbag 31 connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com