A kind of high water permeability powder coating and preparation method thereof

A powder coating and wax powder technology, which is applied in powder coatings, polyester coatings, anti-corrosion coatings, etc., can solve the application limitations, water-based inorganic anti-seepage coatings have insufficient water seepage resistance to meet the needs of consumers, and no specific proposals are proposed Solutions and other problems to achieve the effect of improving compactness, improving hydrolytic stability, and improving water vapor resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

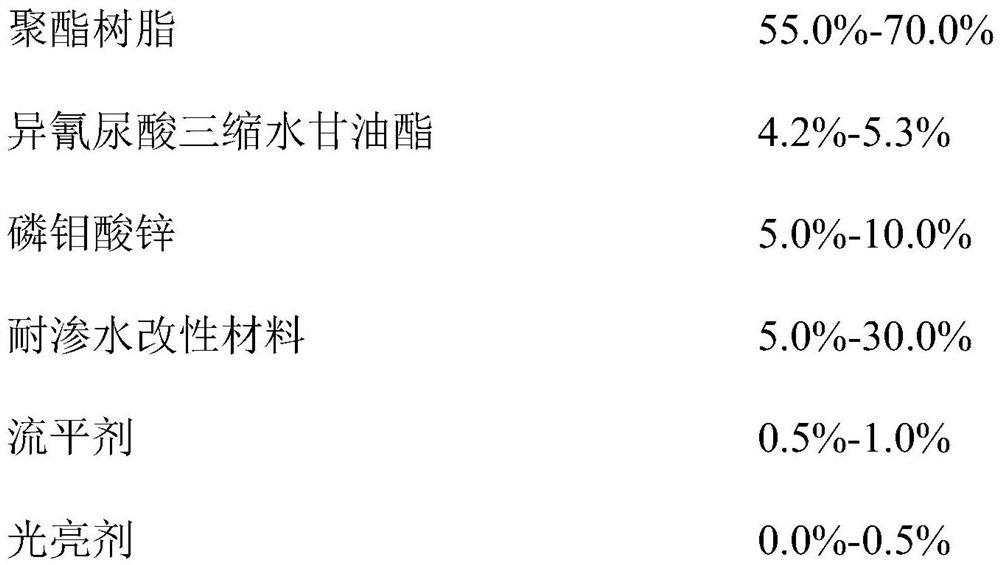

[0031] A high water-penetration-resistant powder coating, the powder coating is prepared from the raw materials in the following weight percentages:

[0032]

[0033] The sum of the weight percentages of the above raw materials is 100%.

[0034] The high water-penetration-resistant powder coating of this embodiment uses polyester resin and water-penetration-resistant modified materials as the main structure, and various additives cooperate to significantly improve the water-penetration resistance of the coating. By changing the ratio of polyester resin to water-resistant modified material and the amount of zinc phosphomolybdate and carbodiimide, the water-resistant performance of the coating can be changed, so that the coating film can achieve better performance.

[0035] Wherein, the acid value of the polyester resin is 32-38 mgKOH / g. Compared with ordinary polyester resin, the coating film has better water seepage resistance and weather resistance;

[0036] The zinc pho...

Embodiment 2

[0046] Accurately weigh the material according to the formula shown in Table 1, place it in a high-speed mixing tank and mix for 3 minutes; extrude the material with an extruder at a temperature of 100°C after mixing; then press into tablets, cool, and crush with an ACM mill The powder machine is crushed to powder particles with an average particle size of 30-35 μm; sieved through a 180-mesh sieve, and packaged into a finished product.

[0047] Table 1 High water permeability powder coating formula

[0048] polyester resin 55.0% Triglycidyl isocyanurate 4.2% Zinc phosphomolybdate 10.0% water-resistant filler 6.7% leveling agent 1.0% brightener 0.5% wax powder 1.0% Benzoin 0.3% Carbodiimide 1.0% antioxidant 0.3% pigment 20.0% total 100%

Embodiment 3

[0050] Accurately weigh the material according to the formula shown in Table 2, place it in a high-speed mixing tank and mix for 3 minutes; extrude the material with an extruder at a temperature of 100°C after mixing; then press into tablets, cool, and crush with an ACM mill The powder machine is crushed to powder particles with an average particle size of 30-35 μm; sieved through a 180-mesh sieve, and packaged into a finished product.

[0051] Table 2 High water permeability powder coating formula

[0052]

[0053]

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com