Preparation method for anchorage reaming bit

A reaming drill bit and anchoring technology, which is applied in the direction of drill bit, drilling equipment, earthwork drilling, etc., can solve the problem that the drill bit cannot be reamed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

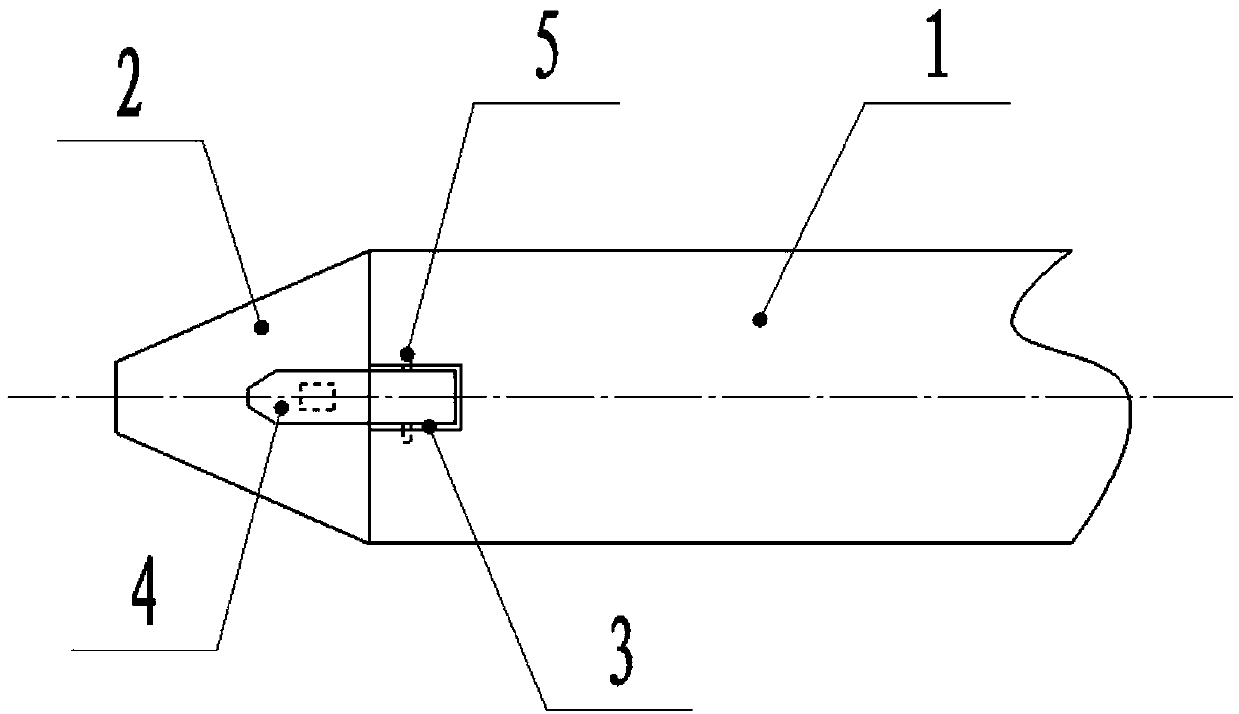

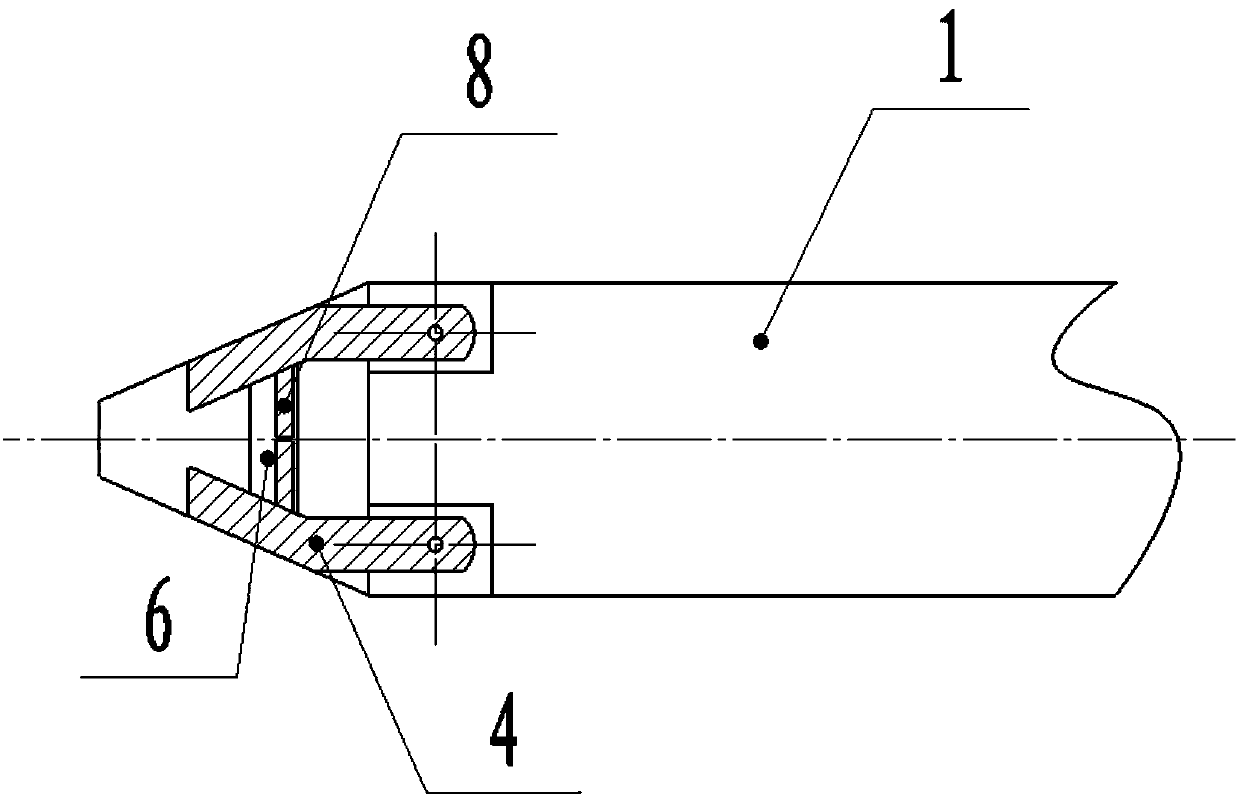

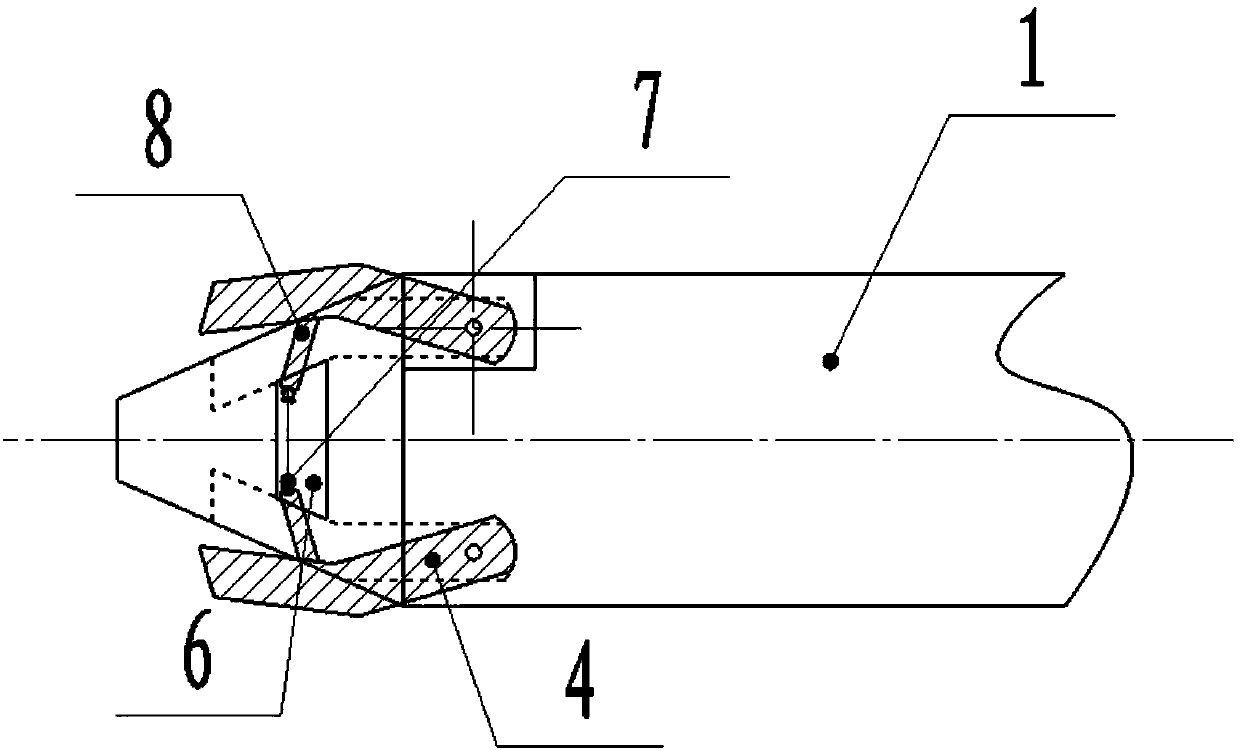

[0029] Such as Figure 1-3 As shown, a kind of anchorage reaming drill bit preparation method of the present invention comprises drill rod 1, and during use, drill rod 1 tail end is installed on the drilling machine, first uses drilling drill bit to drill, after drilling, use expander of the present invention The drill bit is used for reaming, the front end of the drill rod 1 is provided with a tip 2, and the two sides of the tip 2 are symmetrically provided with a reaming wing knife groove 3, and the reaming wing knife groove 3 is provided with a reaming wing knife 4 , the reaming wing knife 4 is a V-shaped structure, the tail end of the reaming wing knife 4 is installed in the reaming wing knife groove 3 through the rotating shaft 5, and the corresponding sharp point between the two reaming wing knife 4 front ends An adjustment through hole 6 is provided on the part 2, and a tension spring 7 for tightening the two reaming wing knives 4 is arranged in the adjustment through h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com