A double-bolt locking mechanism

A locking mechanism and pin technology, applied in the direction of fixing devices, mechanical equipment, bolts, etc., can solve the problems of inconvenient insertion and extraction of pins, and achieve the effects of ensuring positioning accuracy, prolonging service life, and enhancing the ability to resist lateral forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

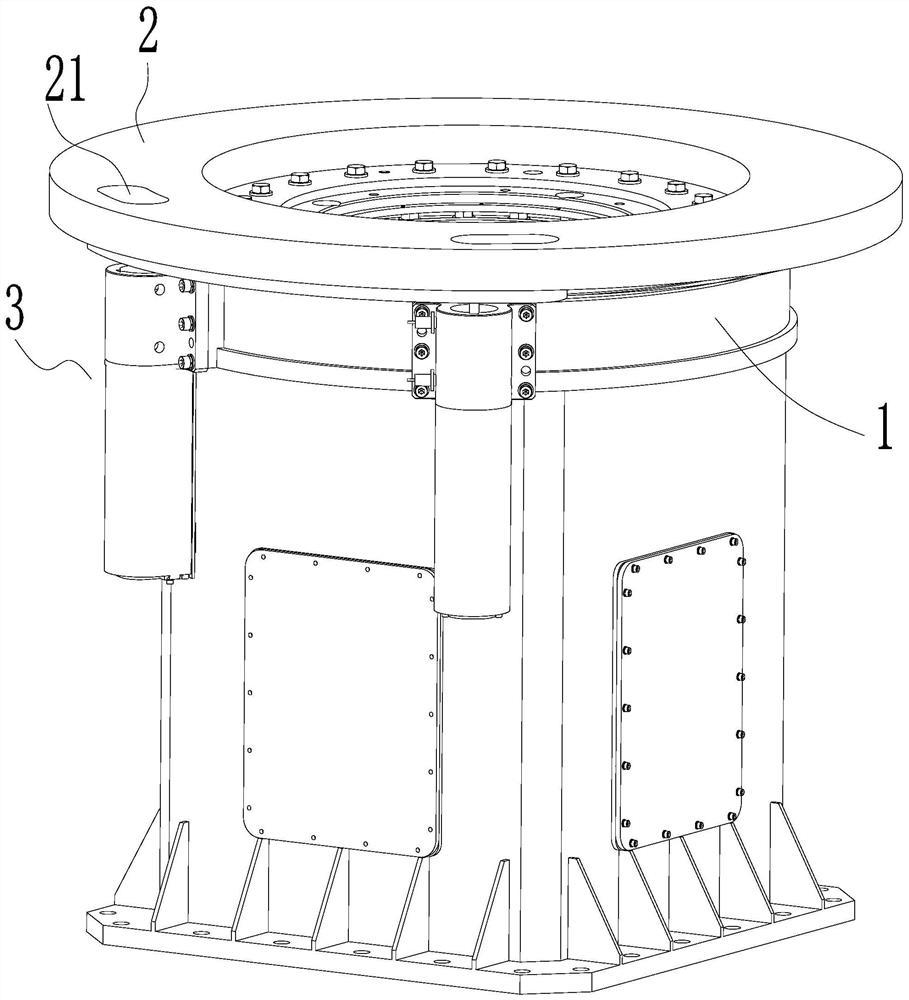

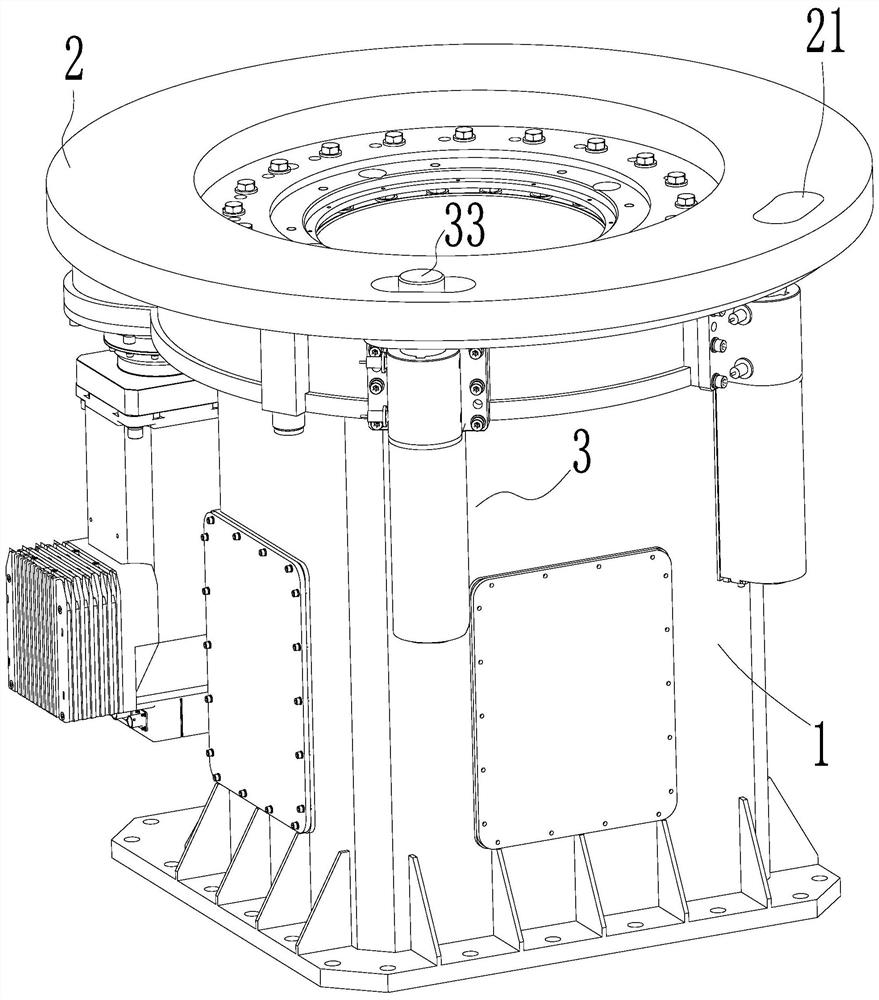

[0051] Such as figure 1 As shown, a double bolt locking mechanism includes a first component 1 capable of sliding relative to each other, a second component 2 , and two latch assemblies 3 installed on the first component 1 .

[0052] The first part 1 is fixed, the first part 1 is a rectangular parallelepiped base, the second part 2 is a rotatable disc, and the second part 2 rotates relative to the first part 1 .

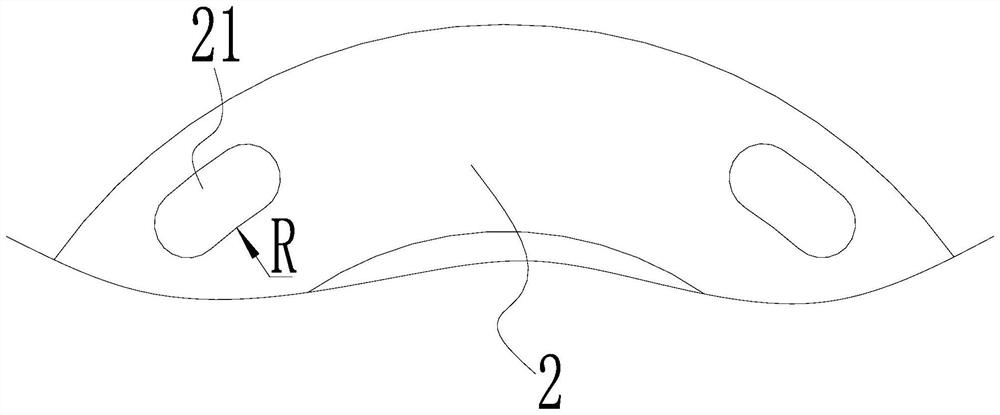

[0053] Such as figure 2 As shown, the second part 2 is provided with two positioning holes 21, and the positioning holes 21 are waist-shaped holes along the direction of the arc of rotation of the second part 2 in the length direction. figure 2 The middle symbol R indicates that the side of the positioning hole 21 is arc-shaped.

[0054] combine figure 1 , 8 -10, the bolt assembly 3 includes a bolt assembly body 31 installed on the first part 1, a bolt driving device 32 arranged on the bolt assembly body 31, and a bolt 33 hingedly arranged at the movable end of...

Embodiment 2

[0059] The difference between this embodiment and Embodiment 1 is:

[0060] Such as Figure 6 , 7 As shown, the first component 1 is fixed, the second component 2 slides linearly relative to the first component 1 , and the positioning hole 21 is a waist-shaped hole whose length direction is along the sliding direction of the second component 2 .

Embodiment 3

[0062] The difference between this embodiment and Embodiment 1 is:

[0063] It also includes a control unit (not shown in the figure), and the plug driving device 32 is connected to the control unit and controlled by the control unit. In this embodiment, the control unit adopts PLC, which can be purchased from the market, and the corresponding control can be realized by programming the PLC.

[0064] Such as Figure 8-10 As shown, the bolt assembly body 31 is provided with a limit switch 312 capable of limiting the stroke of the bolt 33, and the limit switch 312 is connected to the control unit. In this embodiment, the limit switch 312 is a proximity switch.

[0065] Specifically, such as Figure 9 As shown, there are two limit switches 312, which are distributed up and down, and avoidance holes are provided at the corresponding positions of the two limit switches 312. The upper limit switch 312 is located at the top when the latch 33 is retracted, and the latch 33 A through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com