Deformable self-connecting self-repairing pipeline

A self-repairing and self-connecting technology, applied to non-detachable pipe connections, pipes/pipe joints/fittings, hoses, etc., can solve problems such as unsolvable pipes, increased work difficulty, inconvenient connection and repair, etc., to achieve convenience The effect of mounting, low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

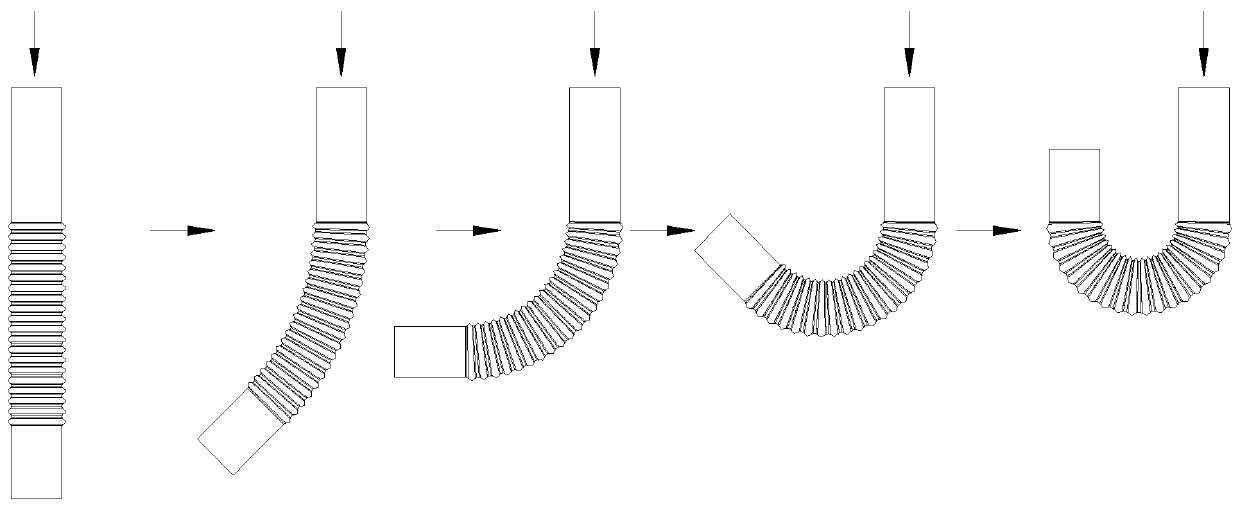

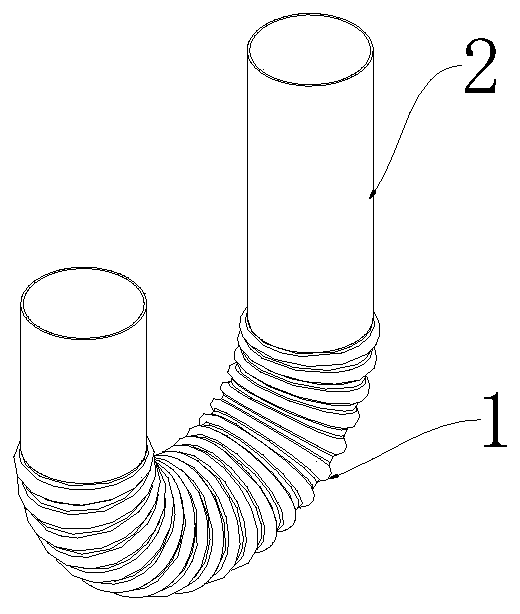

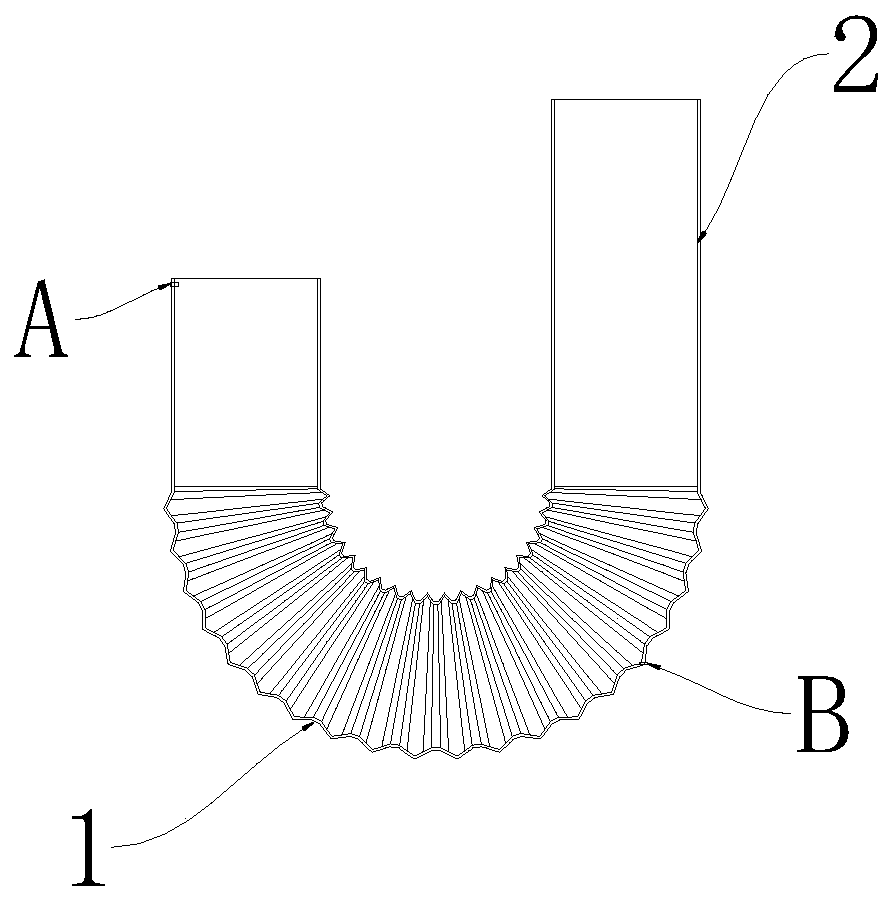

[0029] Under many complex working conditions, the pipeline cannot be completely opened. For example, the diameter of small pipelines such as water and sewage in residential buildings is fixed, and the ground cannot be damaged, but the pipeline still needs to be replaced, repaired or installed. When laying the pipeline network during construction, there are Other lines cannot be fully excavated for open construction environments, etc. The pipes used in the current pipelines are mainly divided into two types. One is the hard pipe with high rigidity, high strength and poor deformation ability. This kind of pipe has a thick wall and cannot be deformed after forming. Satisfy some non-standard size situations; the other is soft pipe with small rigidity, low strength and good deformation ability. This kind of pipe has a thin wall, although it has a certain deformation ability, it has small Damaged, soft pipes are prone to accumulate impurities and dirt, resulting in blockages, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com