A phase change heat storage one-way heat transfer device and its manufacturing method

A technology of phase change heat storage and manufacturing method, which is applied in the direction of heat storage equipment, indirect heat exchangers, heat exchanger types, etc., to achieve remarkable energy-saving effects, high thermal conductivity, and energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

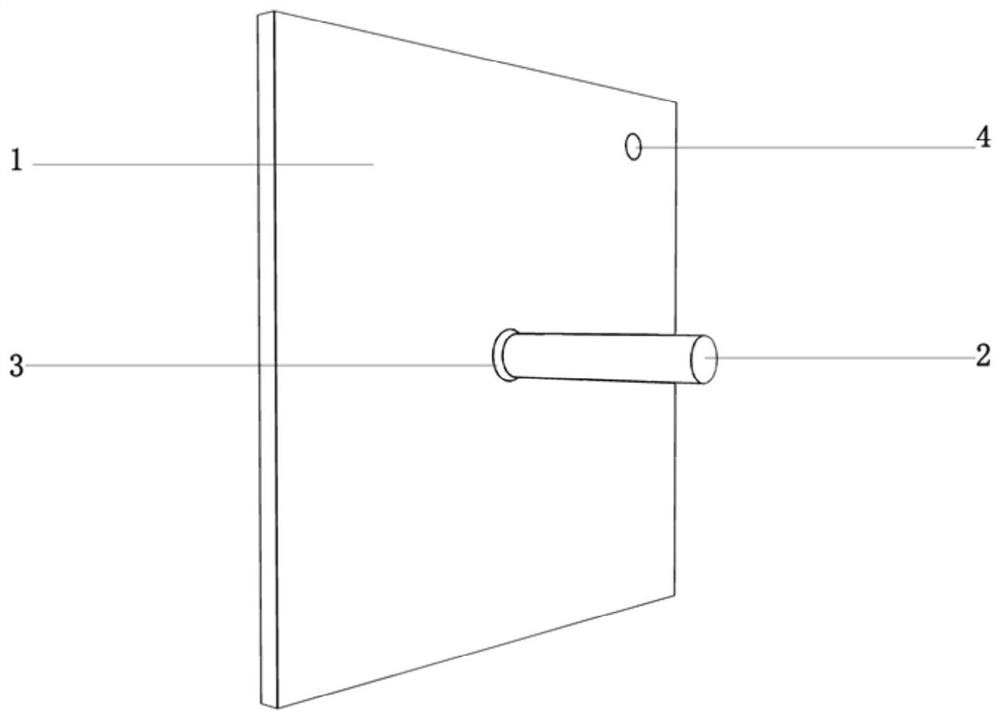

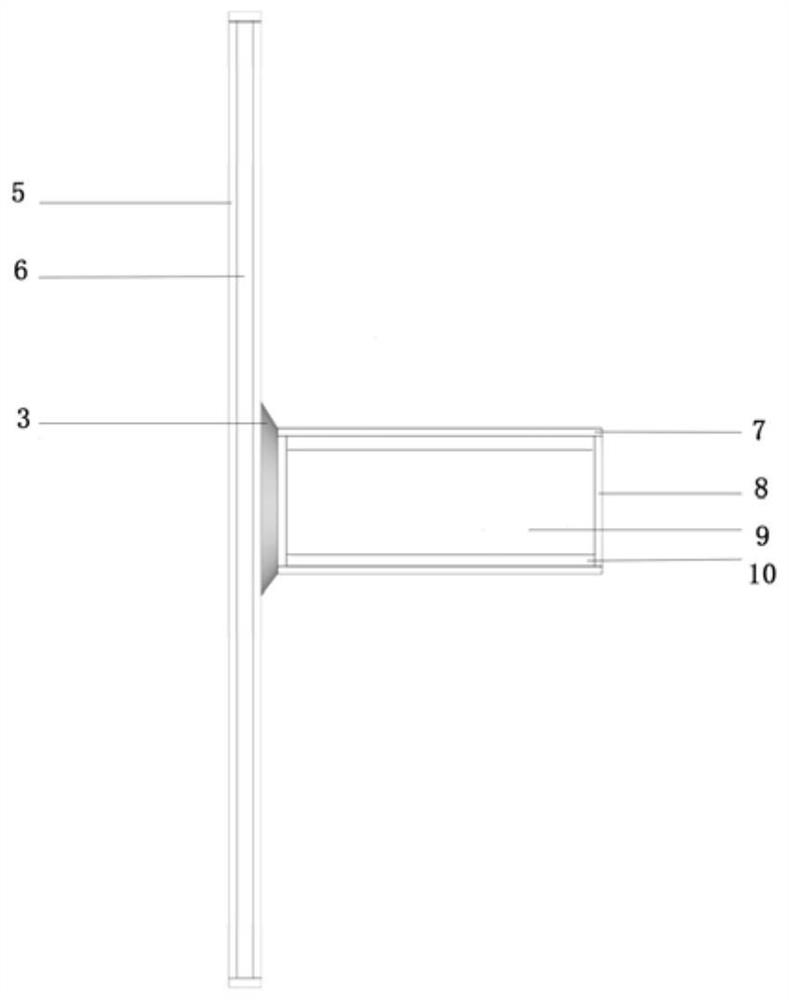

[0043] A phase change heat storage unidirectional heat transfer device, comprising interconnected phase change heat storage aluminum plates 1 and heat pipes 2, the phase change heat storage aluminum plate 1 includes a hollow aluminum plate 5, a phase change material 6 filled in the hollow aluminum plate 5, and The sealant 4 that seals the phase change material 6 in the hollow aluminum plate 5 , the heat pipe 2 includes the tube shell 7 , the tube core 10 on the inner wall of the tube shell 7 , and the working liquid 9 filled in the cavity of the tube core 10 .

[0044] The phase-change heat storage aluminum plate 1 and the heat pipe 2 are connected by heat-conducting adhesive sealing silicone rubber 3 . One end of the heat pipe 2 is connected to the geometric center point of the phase change heat storage aluminum plate 1 . The sealant 4 is any one or a mixture of polyurethane glue, organic silica gel, and acrylic glue. The hollow aluminum plate 5 is a square with a side lengt...

Embodiment 2

[0055] A phase change heat storage unidirectional heat transfer device, comprising interconnected phase change heat storage aluminum plates 1 and heat pipes 2, the phase change heat storage aluminum plate 1 includes a hollow aluminum plate 5, a phase change material 6 filled in the hollow aluminum plate 5, and The sealant 4 that seals the phase change material 6 in the hollow aluminum plate 5 , the heat pipe 2 includes the tube shell 7 , the tube core 10 on the inner wall of the tube shell 7 , and the working liquid 9 filled in the cavity of the tube core 10 .

[0056] Outdoor cabinets for various electrical equipment, such as outdoor communication cabinets, etc., often have an internal temperature of 40-60°C, which seriously affects the performance of electronic devices and poses a greater safety hazard. One-way heat transfer to the outside is required, and the heat pipe 2 is arranged outside the cabinet. If the organic fatty acid phase change material 6 with a phase change t...

Embodiment 3

[0058] A phase change heat storage unidirectional heat transfer device, comprising interconnected phase change heat storage aluminum plates 1 and heat pipes 2, the phase change heat storage aluminum plate 1 includes a hollow aluminum plate 5, a phase change material 6 filled in the hollow aluminum plate 5, and The sealant 4 that seals the phase change material 6 in the hollow aluminum plate 5 , the heat pipe 2 includes the tube shell 7 , the tube core 10 on the inner wall of the tube shell 7 , and the working liquid 9 filled in the cavity of the tube core 10 .

[0059] The high-altitude areas in western my country are rich in solar energy resources. When the solar collector uses water as the medium, it is easy to cause problems such as high-temperature tube explosion in summer and freezing at night in winter. This device can be combined with the collector to effectively use solar radiation to heat the air for heating. . One-way heat transfer inward is required, and the heat pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com