Backlight module structure

A backlight module and backplane technology, which is applied in optics, nonlinear optics, instruments, etc., can solve the problems of difficult to control the size of the plastic frame buckle, difficult to get stuck, and jumping out, so as to reduce the impact of size matching and reduce product costs , The effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

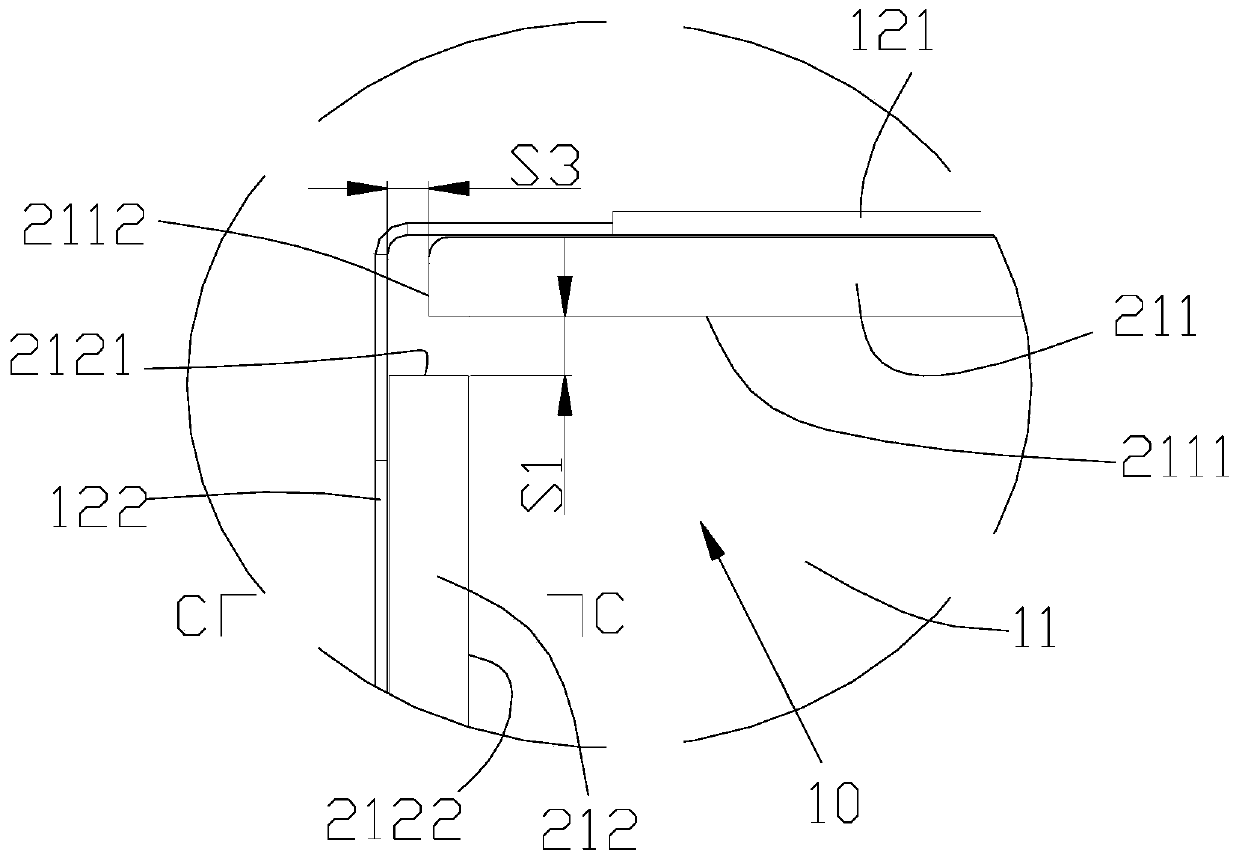

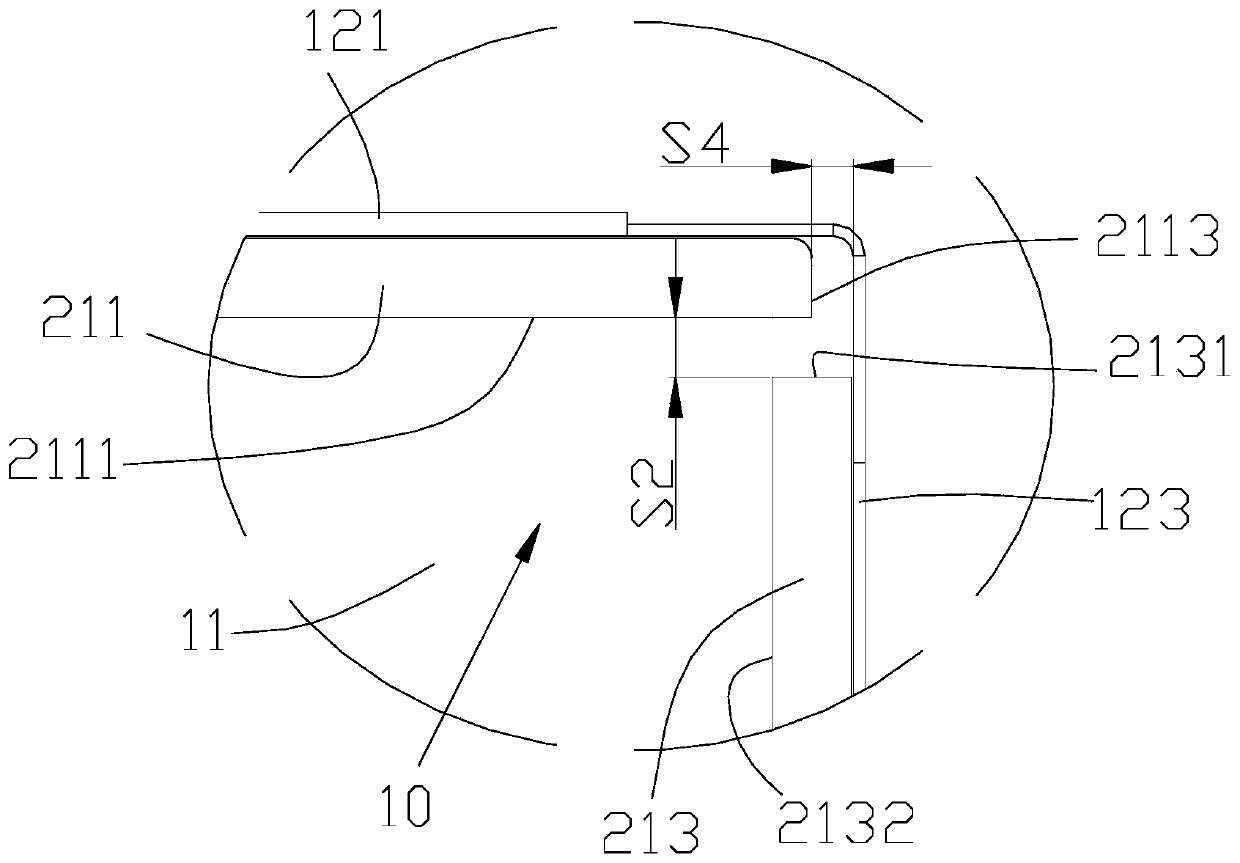

[0023] In the present application, the direction toward the inside of the back plate 10 is referred to as the inner side or the inner side, and the direction opposite to the inner side or the inner side is called the outer side or the outer side.

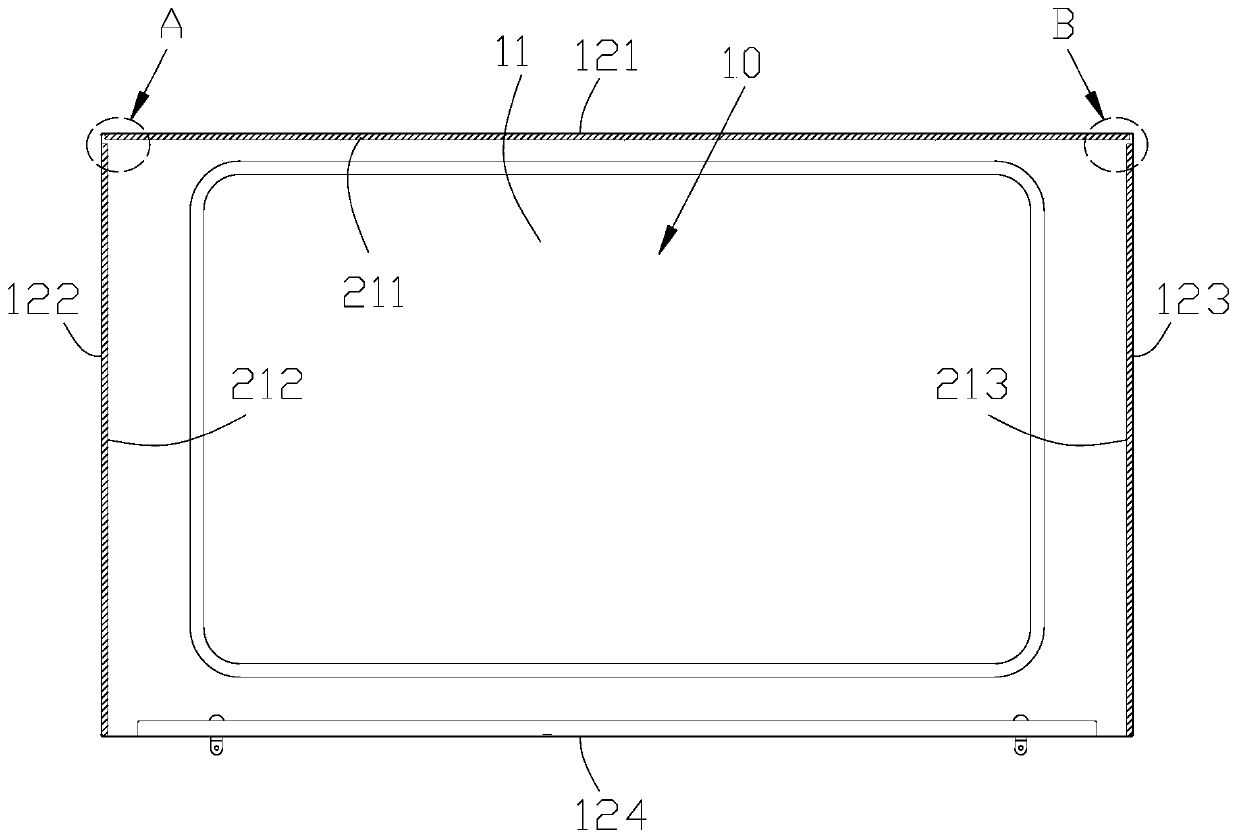

[0024] see figure 1 , a backlight module structure, which includes a backplane 10, the backplane 10 includes a rectangular body 11, four sidewalls are provided on the four edges of the body 11, and the four sidewalls are called first in turn. The light blocking side wall 121, the second light blocking side wall 122, the third light blocking side wall 123 and the light incident side wall 124, wherein the first light blocking side wall 121, the second light blocking side wall 122 and the third light blocking side wall The walls 123 are collectively referred to as light-blocking side walls.

[0025] The first light-shielding sidewall 121 is arranged opposite to the light-incident sidewall 124 , and the second light-shielding sidewall ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com