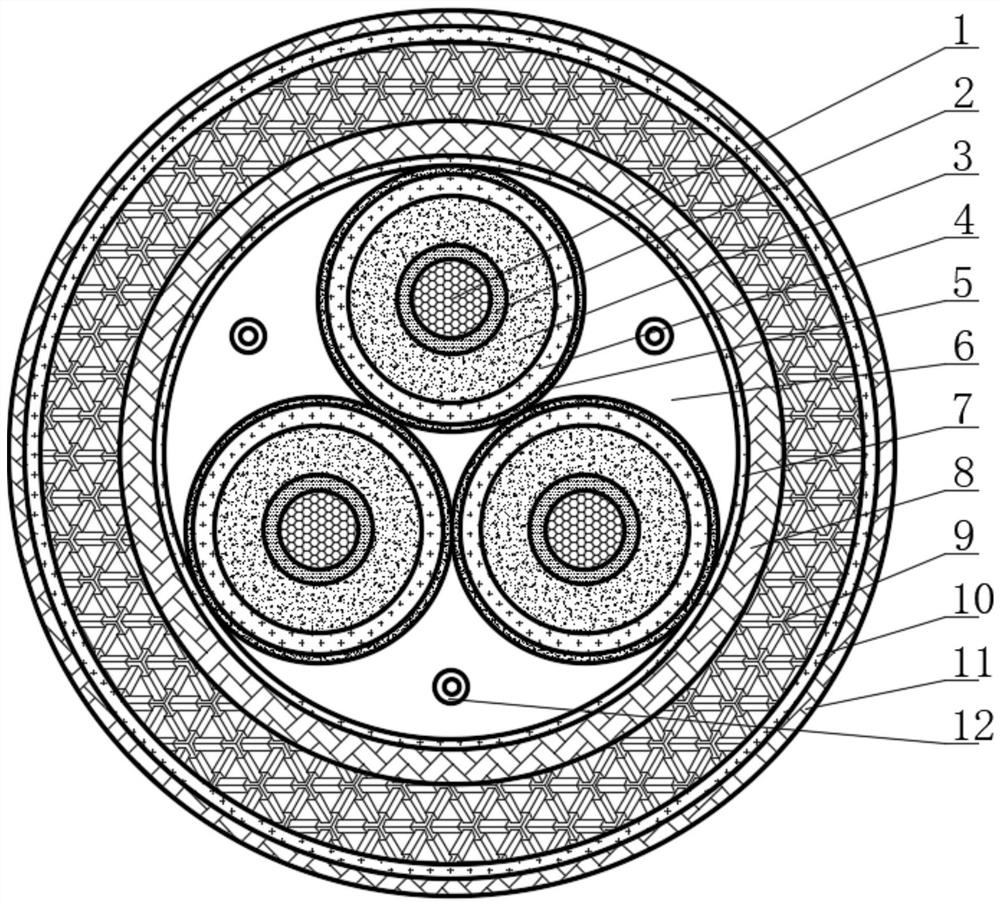

A dual-purpose submarine double-three-core cable for communication and electric power and its manufacturing method

A three-core cable and manufacturing method technology, applied in communication cables, submarine cables, cable/conductor manufacturing, etc., can solve the problems of high manufacturing cost, many riverbed roads, long production cycle, etc., to improve comprehensive mechanical properties and enhance buffering. The effect of performance and high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

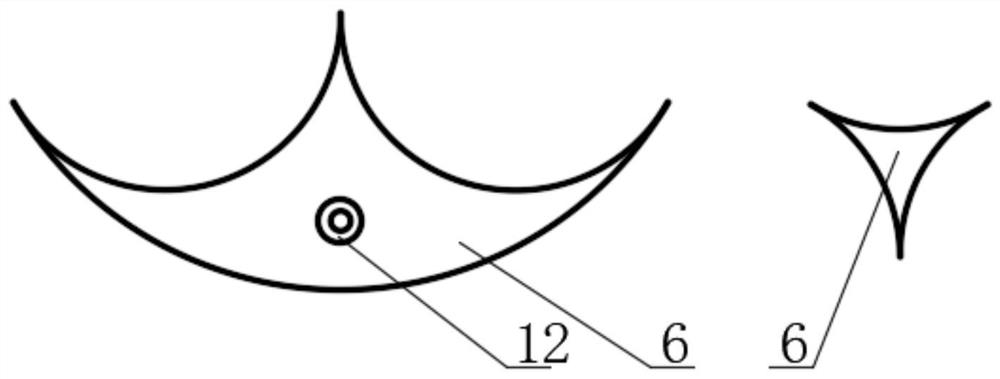

[0037] A dual-purpose submarine double-three-core cable for communication and power. The overall structure is a three-core cable. Each core 1 is made of 30 pure copper cores and compressed into a cylindrical core 1 with a diameter of φ38.2mm by using a polycrystalline mold at a density of 91%. The outer surface of each core 1 is covered with PVC material. Electrostatic coating film 2; each core tube is provided with a core body 1, an electrostatic coating film 2, an insulating layer 3, a single-core self-fixing water-blocking belt 4 and a single-core coating layer 5 from the inside and the outside; the outer protective sleeve From the inside and outside, there are inner lining self-fixing water blocking tape 7, inner lining layer 8, steel wire armor layer 9, outer lining self-fixing water blocking tape 10, and outer lining layer 11; The gaps between the solid strips 6 are filled with solid strips 6, which are sealing strips made of epoxy resin in a shape that matches the core ...

Embodiment 2

[0073] The whole is consistent with Example 1, the difference is:

[0074] The outer diameter of the submarine cable is 270mm, and each core 1 in it is made of 30 pure copper cores and compressed into a cylindrical core 1 with a diameter of φ38.8mm by a polycrystalline mold at a density of 89%. The solid-blocking water belt 4, the inner lining self-fixing water belt 7 and the outer lining self-fixing water belt 10 are all made of indium oxide: tin oxide: calcium oxide: magnesium oxide: iron oxide in a mass ratio of 45:6:1.8:1 : 0.6 ratio of the mixed mixture is raw material, after evaporation on the surface of the plane pure copper plate, the conductive self-curing film that adopts the NaOH aqueous solution of 1.5% mass concentration to be initially solidified and then demolded to take off;

[0075] The manufacturing method of above-mentioned cable, comprises the following steps:

[0076] 1) Raw material preparation

[0077] ① Raw material preparation: prepare indium oxide 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com