A flameless heater

A heater and flameless technology, applied in the direction of induction heating, ohmic resistance heating, induction heating devices, etc., can solve the problems of low heating efficiency of the heating gun head, high loss of magnetic force lines, and slow heating speed, so as to avoid the breakage of the condenser tube, High heating efficiency and fast heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

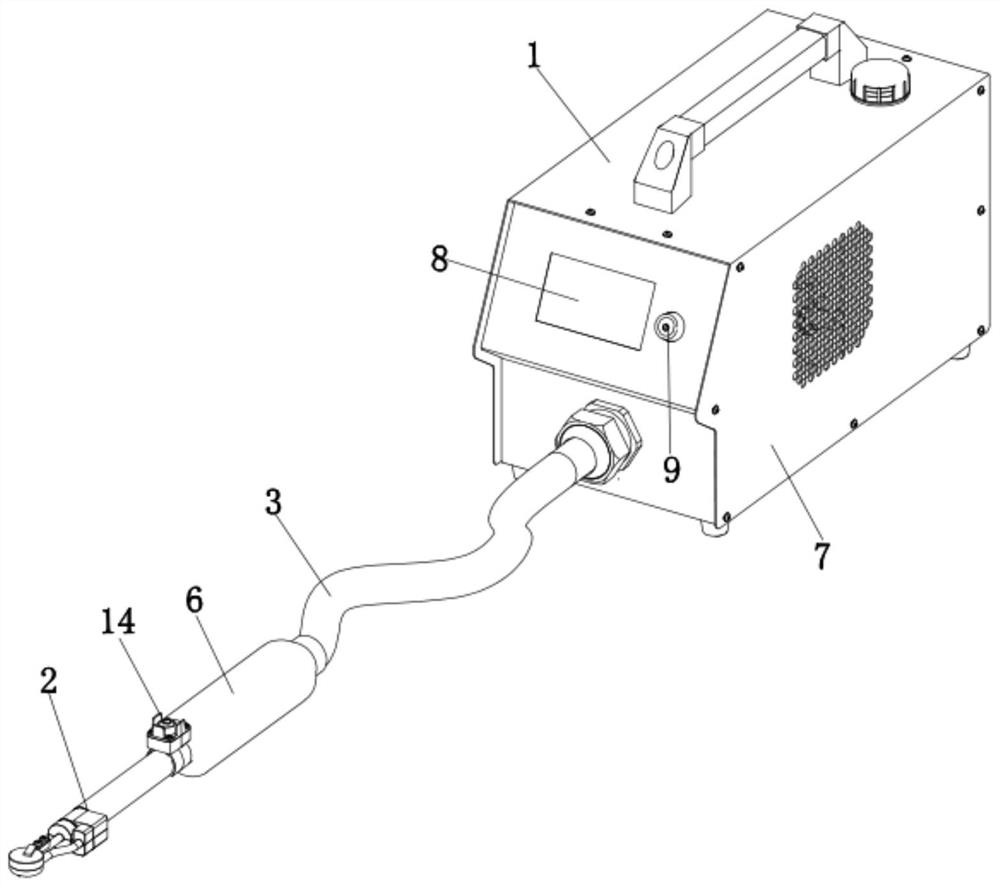

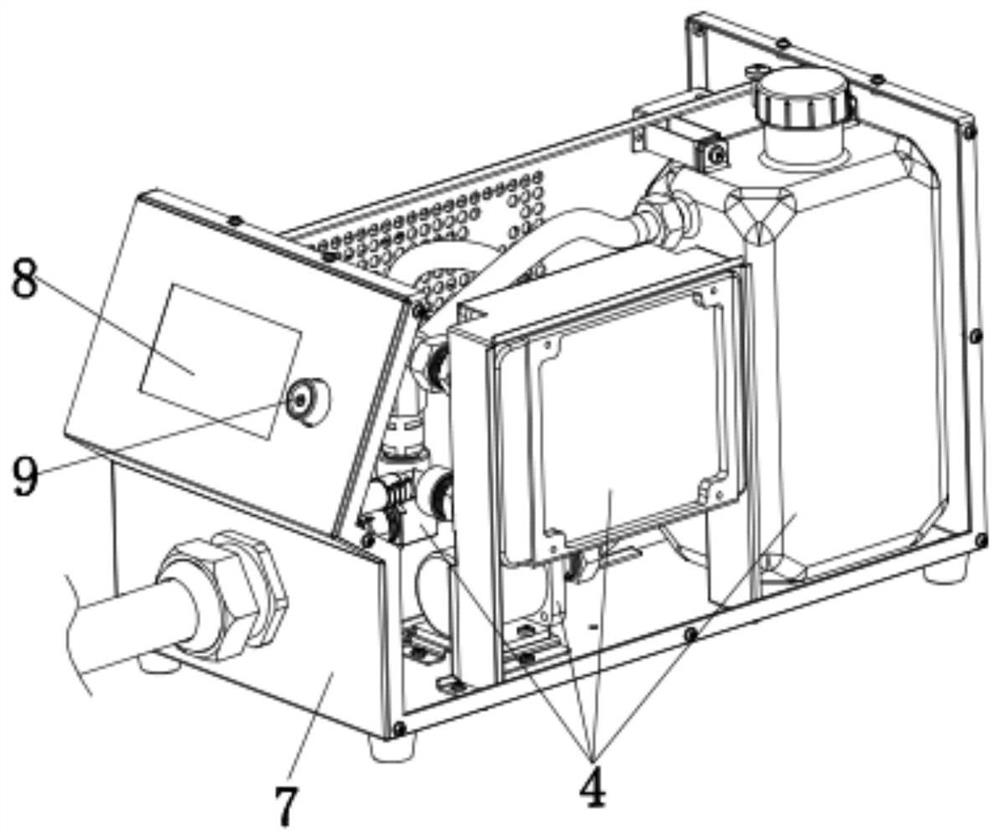

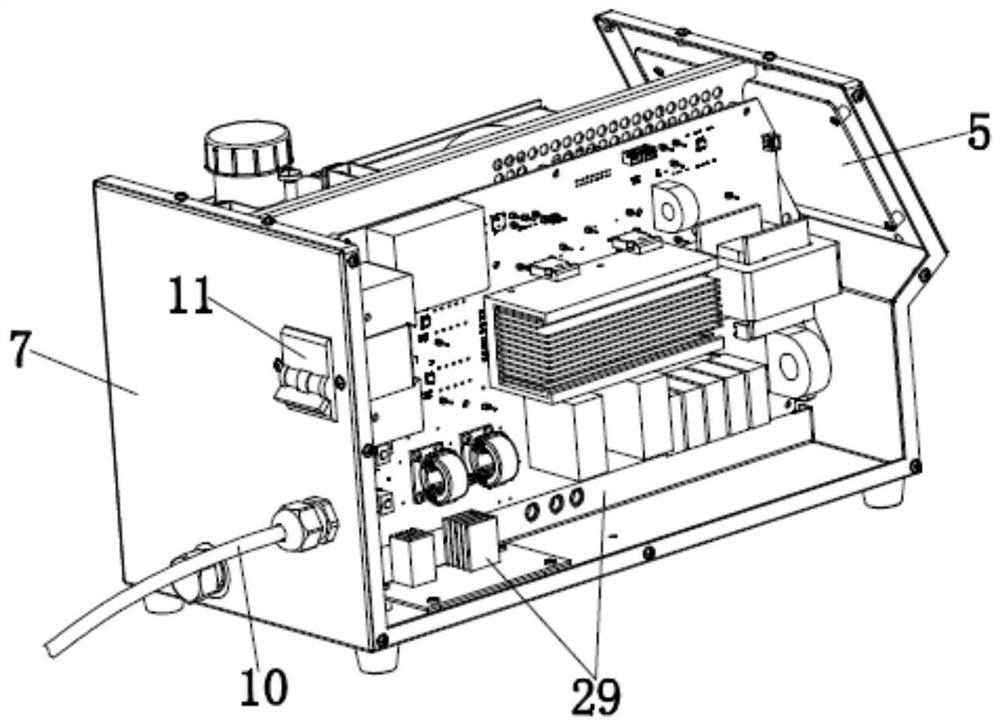

[0033] Embodiment 1: This embodiment relates to a flameless heater, such as Figure 1-3 As shown, it includes: a host 1 , a heating gun head 2 and a flexible pipe 3 .

[0034] Such as Figure 1-3 As shown, a cooling system 4 and a control system 5 are arranged in the main engine 1 . The cooling system 4 is used to realize the circulation of the coolant in the host 1 in the heating gun tip 2 , so as to cool down the heating gun tip 2 and prolong the service life of the heating gun tip 2 . The control system 5 is used to control the flameless heater, so as to ensure the safety of users and improve the use safety of the flameless heater. The heat gun head 2 is arranged on one side of the main machine 1, and the heat gun head 2 is used for heating the metal to be heated. One end of the flexible pipe 3 is sealed and assembled with the liquid outlet of the cooling system 4, and the other end is sealed and assembled with the heating gun head 2. The flexible pipe 3 is used to trans...

Embodiment 2

[0043] Embodiment 2: The difference between this embodiment and Embodiment 1 is that, as Figure 8-11 As shown, in this embodiment, the heating conductive member 20 is a heating conductive block 28 , one end of the heating conductive block 28 is assembled with the second mounting head 18 , and the other end is assembled with the third mounting head 19 . A guide groove is provided in the heating conductor 20 , and the guide groove is used to communicate with the through grooves of the third installation head 19 and the second installation head 18 , so as to realize the circulation and backflow of the cooling liquid. The heating conduction block 28 is arranged on the upper end of the first installation head 17 (referring to as Figure 8 , 9 ) or side-end (refer to eg Figure 10 , 11 ). When the heating conduction element 20 is a heating conduction block 28 , the magnetism collecting device 15 includes: a magnetic element 25 embedded on the heating conduction element 20 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com