Screening and conveying structure used between ultrafine grinding processes of bearing

A grinding process and bearing technology, which is applied in the direction of manufacturing tools, grinding feed movement, metal processing equipment, etc., can solve the problem of defective products flowing into the next process, and achieve the effects of small space occupation, simple structure, and reduced work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

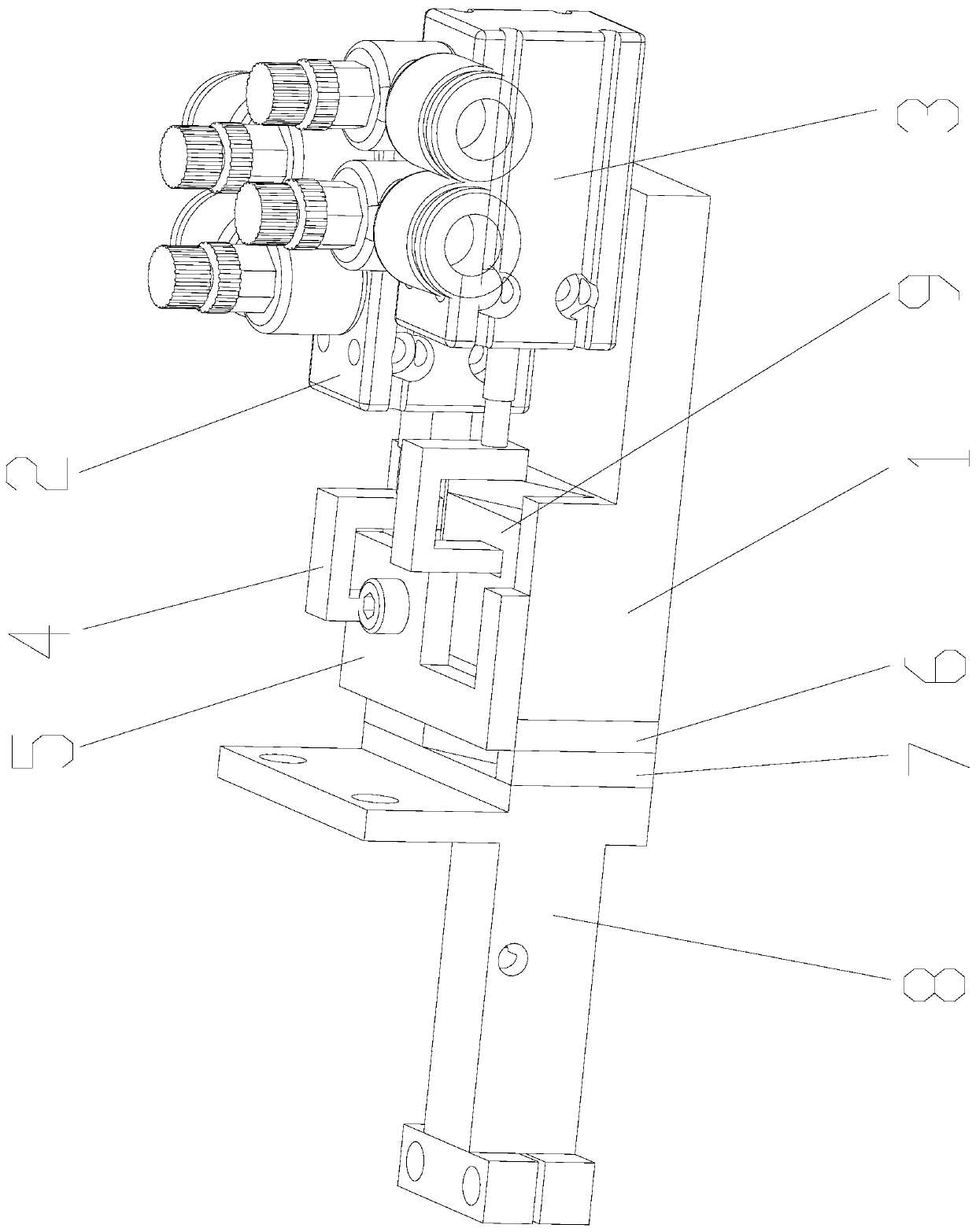

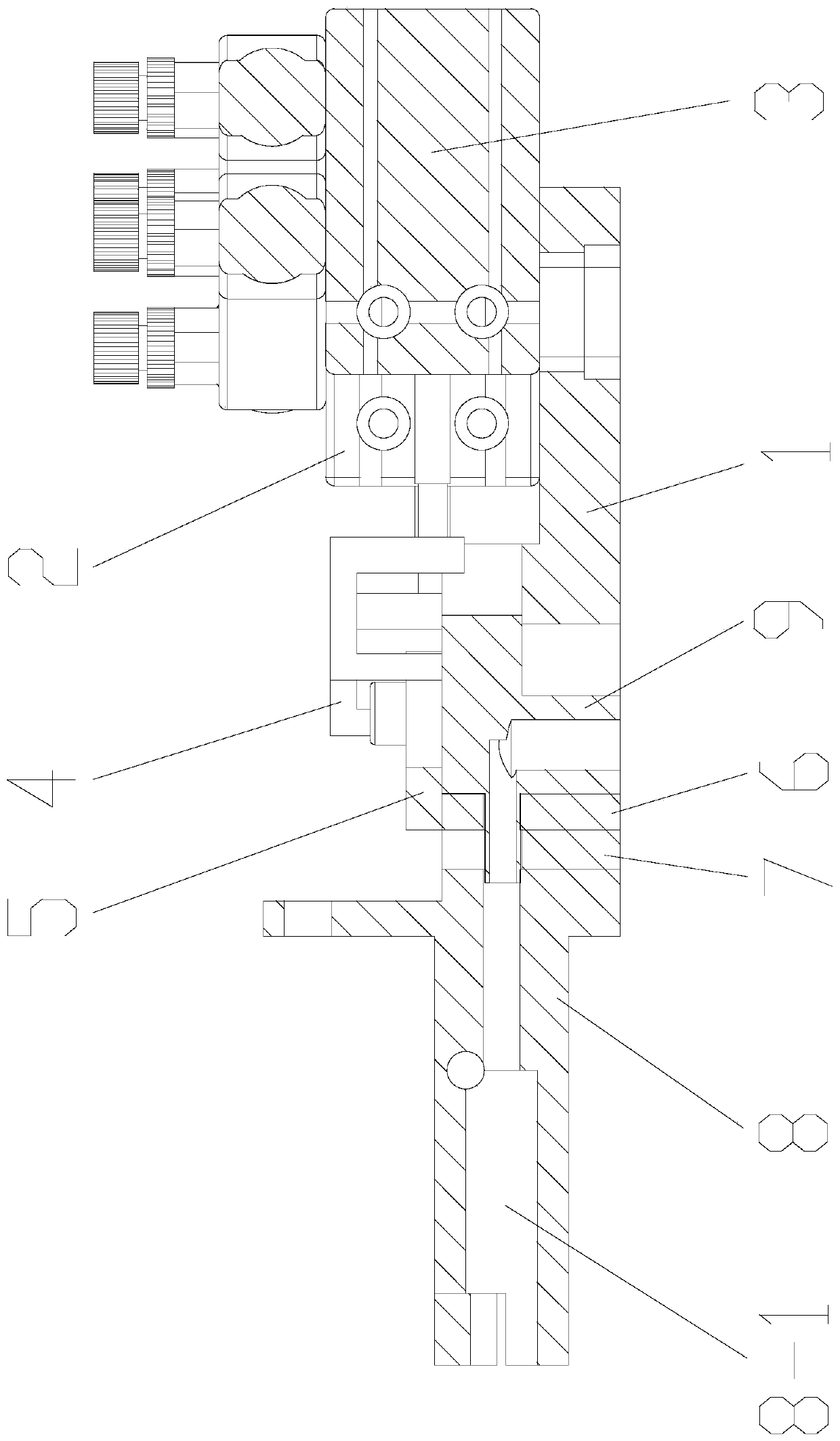

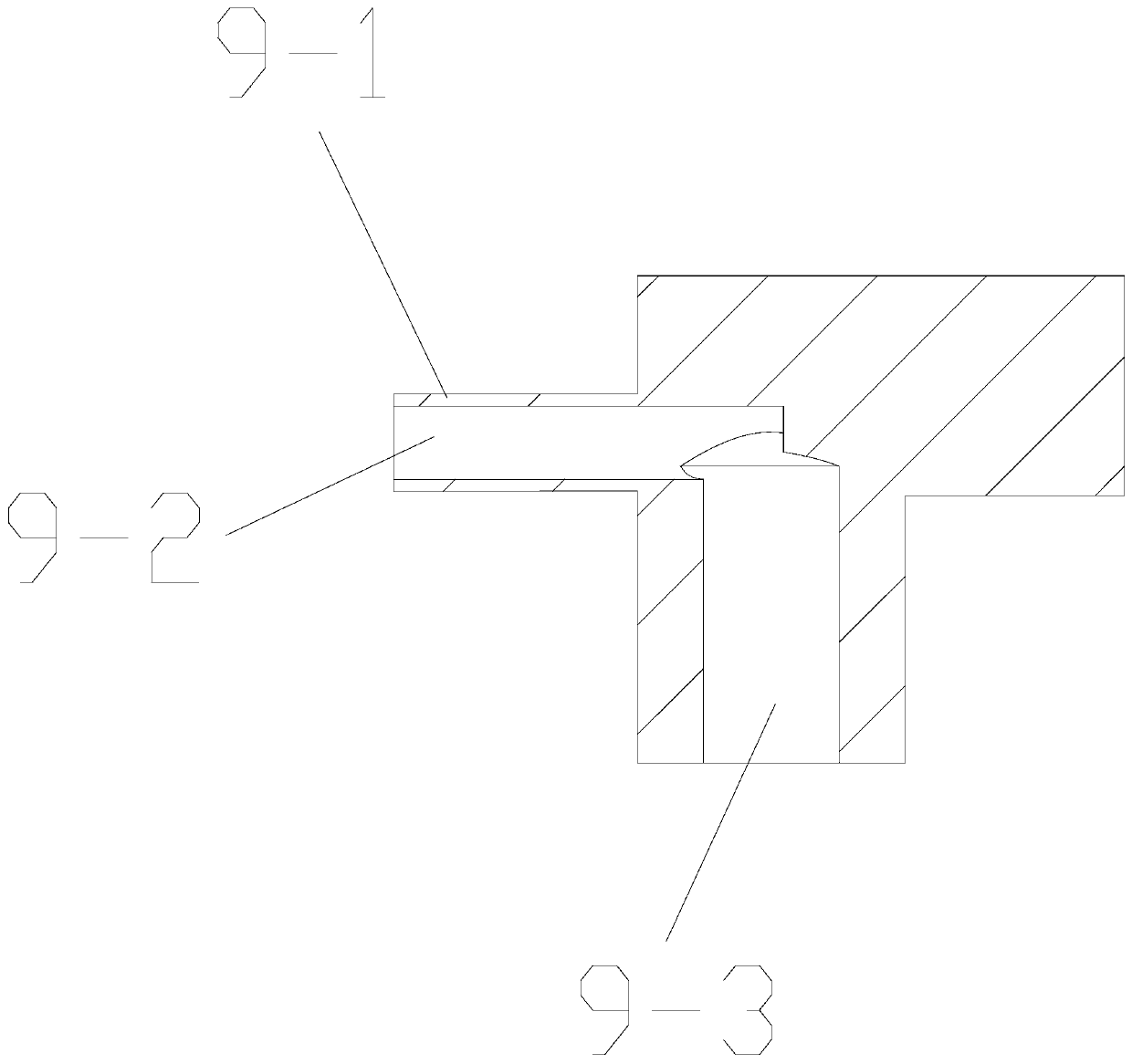

[0017] Figure 1-3 Among them, including installation plate 1, screening cylinder 2, conveying cylinder 3, connecting rod 4, screening block 5, baffle plate 6, conveying block 7, conveying pipe 8, conveying hole 8-1, conveying hole 8-1, pushing finger 9. Finger pushing part 9-1, oil hole 9-2, oil inlet hole 9-3, etc.

[0018] Such as Figure 1-2 As shown, the present invention is a screening and conveying structure between bearing superfine grinding processes, including a mounting plate 1, a screening cylinder 2 is arranged on the mounting plate 1, the piston end of the screening cylinder 2 is connected to a connecting rod 4, and the connecting rod 4 is fixedly connected to a screening block 5 The screening block 5 is slidably connected to the top of the mounting plate 1, and the conveying cylinder 3 is arranged on one side of the screenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com