Blade, impeller structure and impeller fastening type spraying machine

A technology of blades and impellers, applied in the field of sandblasting, which can solve problems such as the inability to obtain smoothness on the surface of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

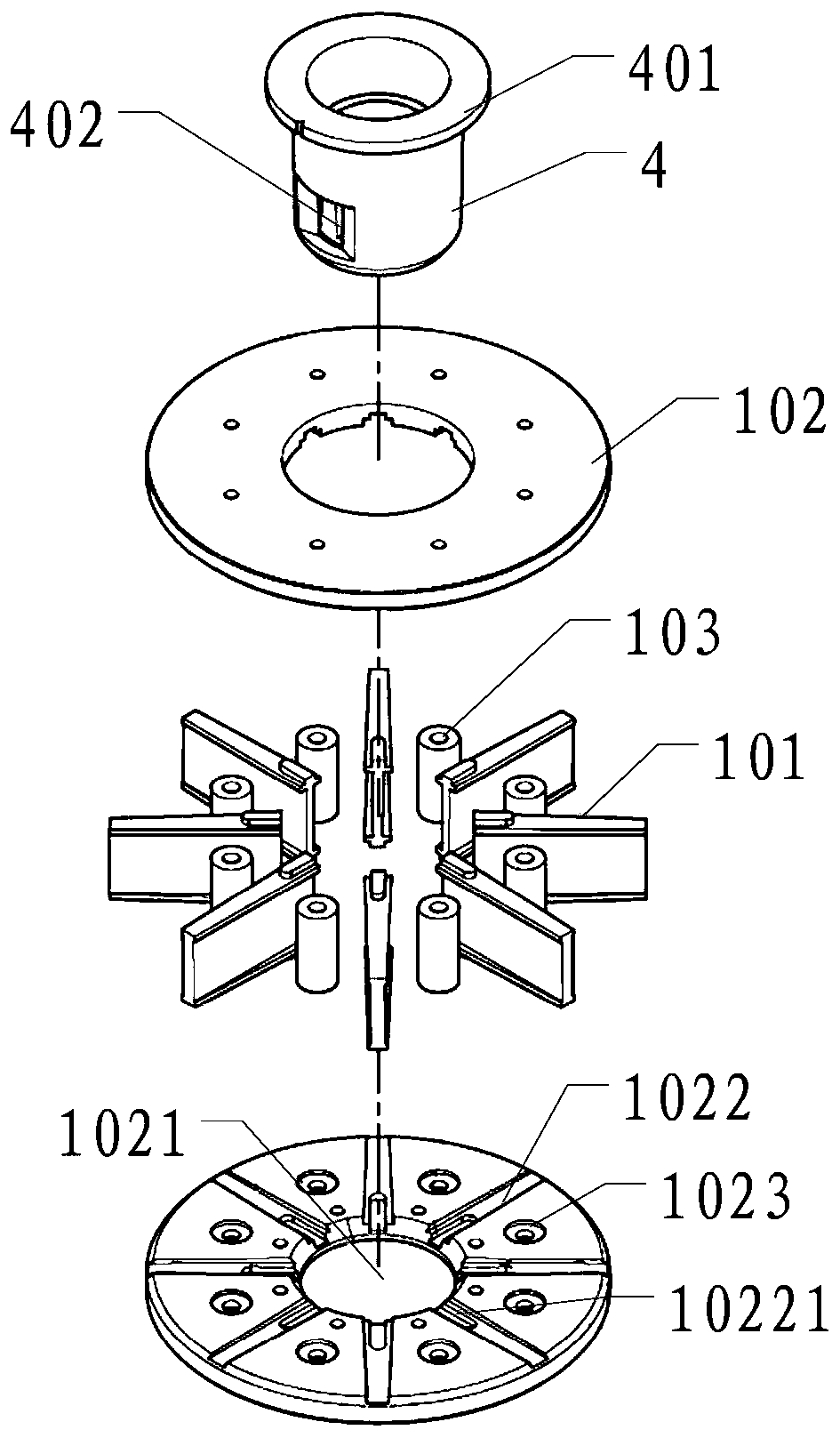

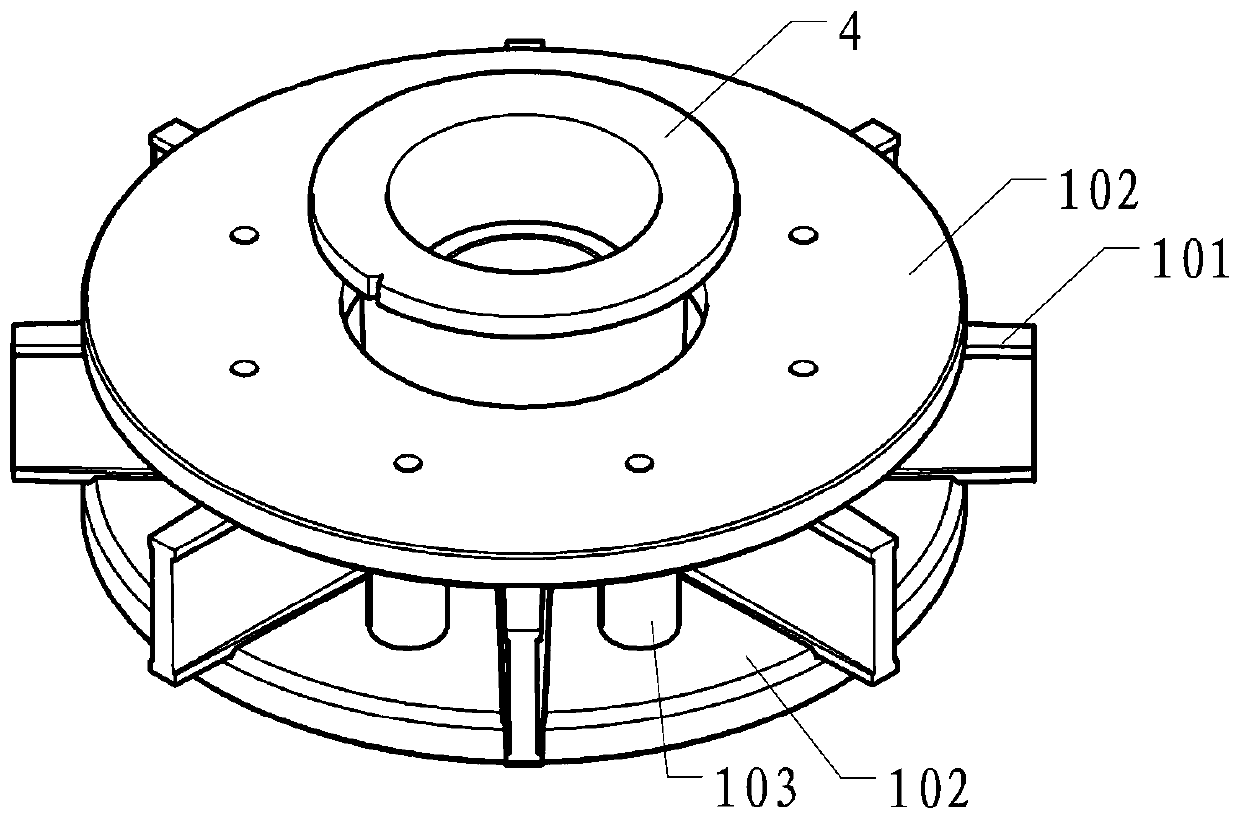

[0043] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, a detailed description will be given below in conjunction with the accompanying drawings and specific embodiments. In the following description, specific details such as specific configurations and components are provided only to help a comprehensive understanding of the embodiments of the present invention. Therefore, it should be clear to those skilled in the art that various changes and modifications can be made to the embodiments described herein without departing from the scope and spirit of the present invention. In addition, for clarity and conciseness, descriptions of known functions and configurations are omitted.

[0044] It should be understood that "one embodiment" or "an embodiment" mentioned throughout the specification means that a specific feature, structure, or characteristic related to the embodiment is included in at least one embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com