A metal surface laser bluing treatment device and method

A metal surface, bluing treatment technology, applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of difficult real-time monitoring of the degree of bluing of the workpiece, inconvenient production and processing, waste of the environment, etc. High energy utilization rate, less environmental pollution, and the effect of protecting workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Taking the metal iron surface as an example to carry out bluing treatment below, introduce the processing principle of the present invention.

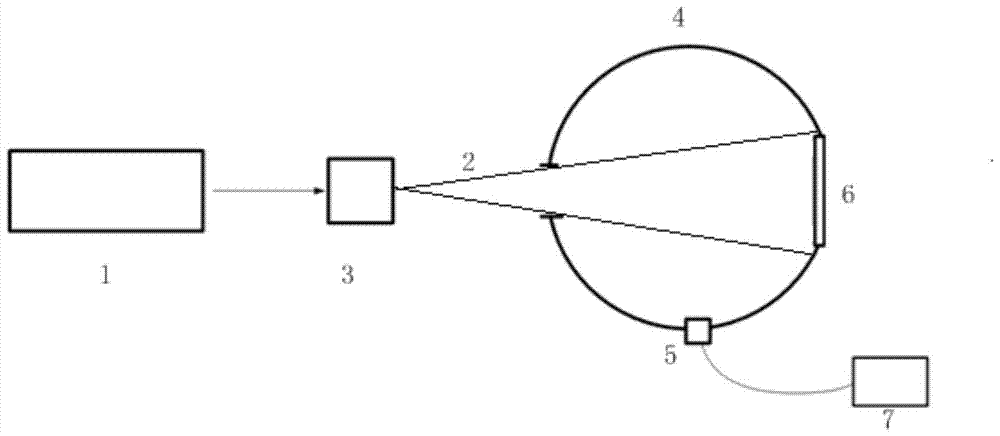

[0026] Such as figure 1 As shown, the beam 2 output by the laser 1 is homogenized and shaped by the beam shaping system 3, and then enters the surface of the workpiece 6 to be blued through the input port of the integrating sphere 4, and the workpiece 6 to be blued is arranged at the output of the integrating sphere 4 After the scattered light on the surface is collected by the integrating sphere, the intensity amplitude signal of the scattered light is recorded by the photodetector 5 arranged on the integrating sphere 4 and the signal recorder 7 at the rear end. The type of photodetector 5 can be selected according to the actual power and wavelength of the laser beam.

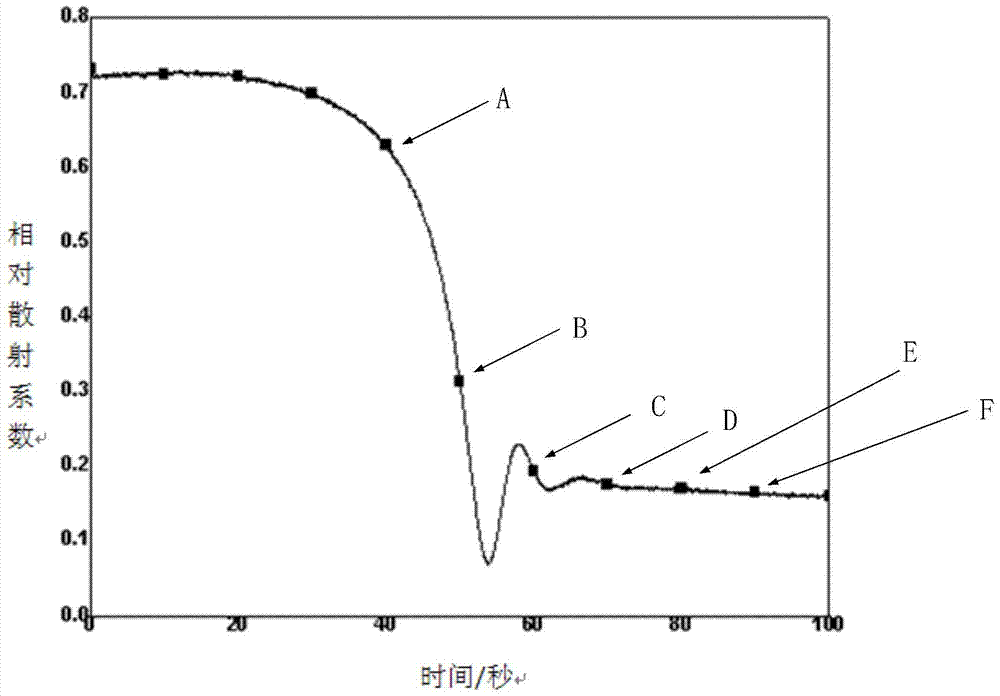

[0027] When the laser beam with a certain power density can quickly heat the metal iron surface, in the air environment, the heated iron surface can quickly un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com