Moss tile and manufacturing method thereof

A production method and moss technology, which are applied to the field of moss tiles and their production, can solve the problems of short life cycle of plants, difficult practical application and implementation, regular replacement of plants, etc., achieve light and thin texture, improve resource utilization rate and product operation efficiency, The effect of beautifying the city

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

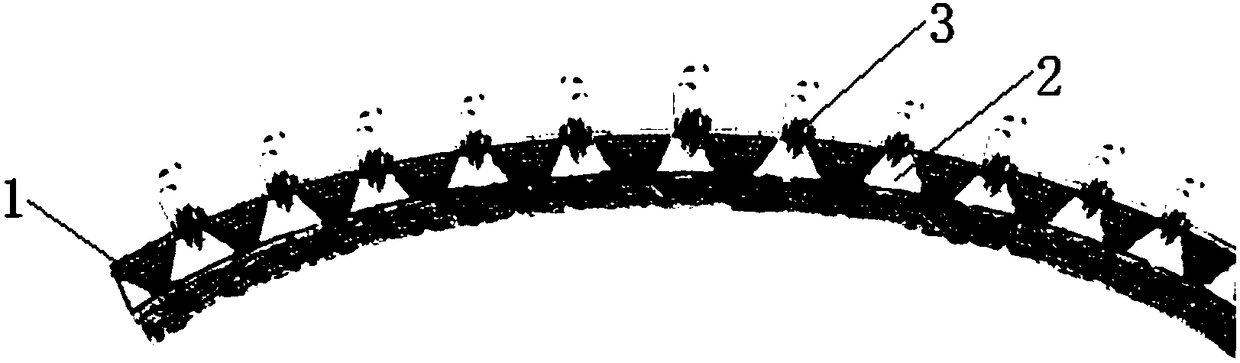

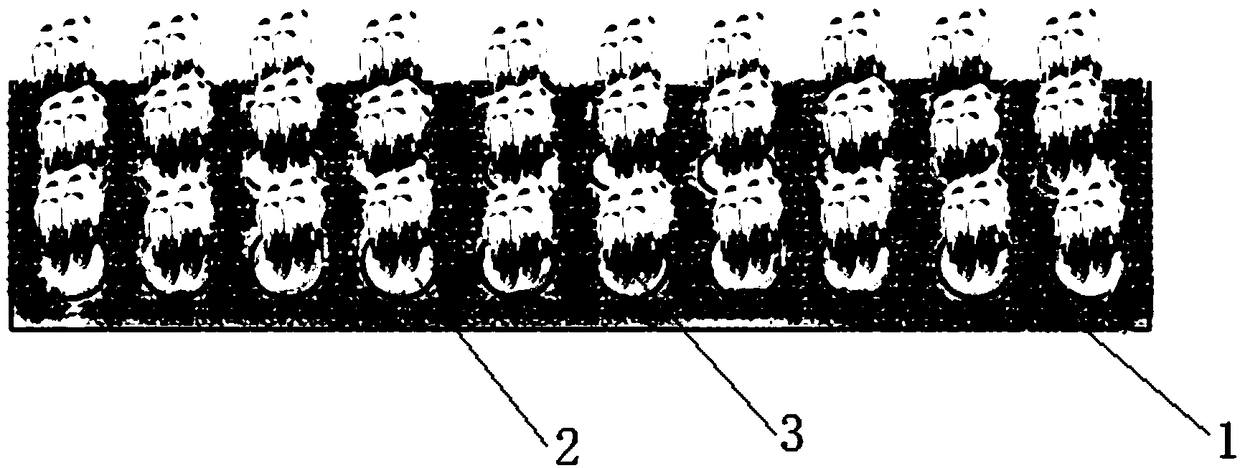

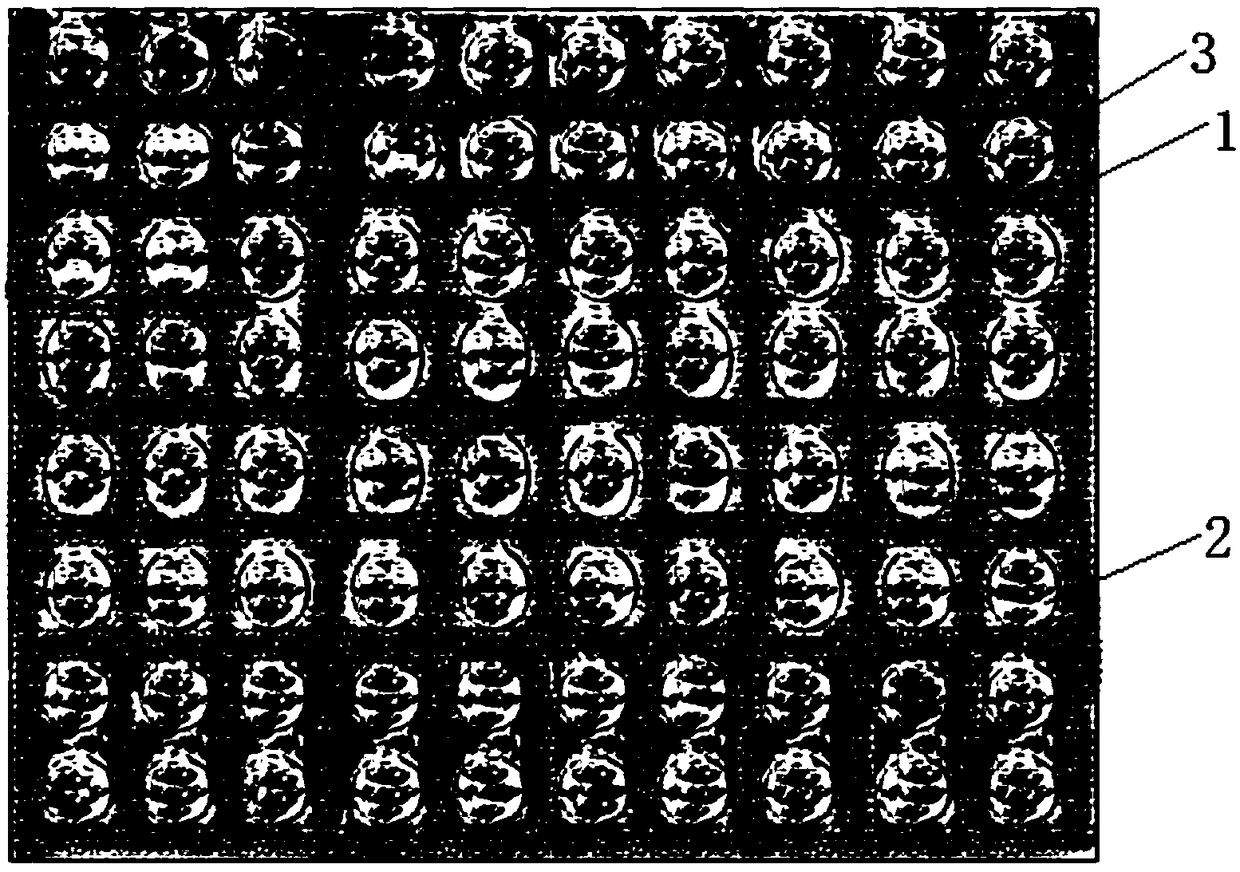

[0037] refer to figure 1 , figure 2 , image 3 , a moss tile with an arc-shaped structure, moss tile 1 is distributed with holes 2, the upper end of the hole 2 extends to the upper surface of the moss tile, and the lower end of the hole 2 has a certain distance from the lower surface of the moss tile , the cavity 2 is in the shape of a conical table with a wide bottom and a narrow top, the cavity 2 is placed with a moss growth substrate, and a green circular moss clump 3 grows there.

[0038] In this embodiment, the moss tiles are made of cement mixed with elm fiber and polyacrylonitrile fiber, and the mass ratio of elm fiber, polyacrylonitrile fiber and cement is 1:1:6. The entire tile is produced by a combination of elm fiber with strong water absorption, polyacrylonitrile fiber with high strength and elastic modulus and cement, so it has high water absorption and strength; the Mohs hardness of the moss tile is 4.5 , with high hardness and service life.

[0039]In this ...

Embodiment 2

[0055] The difference from Embodiment 1 is that this embodiment provides another method for making moss tiles, including the following steps:

[0056] 1) Make arc-shaped moss tiles. Holes are distributed on the moss tiles. The upper end of the holes extends to the upper surface of the moss tiles. There is a certain distance between the lower end of the holes and the lower surface of the moss tiles. The holes are lower width. upper narrow frustum shape;

[0057] 2) Evenly spread the moss growth substrate in the cavity;

[0058] 3) Moss planting: take the moss gametophytes in the natural growth state, dry them naturally, crush the gametophytes, use them as propagation materials, place them on the pre-configured medium, spray them with tap water to moisturize for one month, and then form green moss clusters ;

[0059] 4) Move the green moss cluster obtained in step 3) into the cavity of the moss tile, and then the green moss cluster can grow from the cavity, and it can be put i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com