A packing and turning table for large diameter synthetic paper film roll products in the film industry

A technology of large-diameter, synthetic paper, applied in the field of packing and turning table, can solve the problems of low packing efficiency, easy occurrence of safety accidents, easy to tilt and fall, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

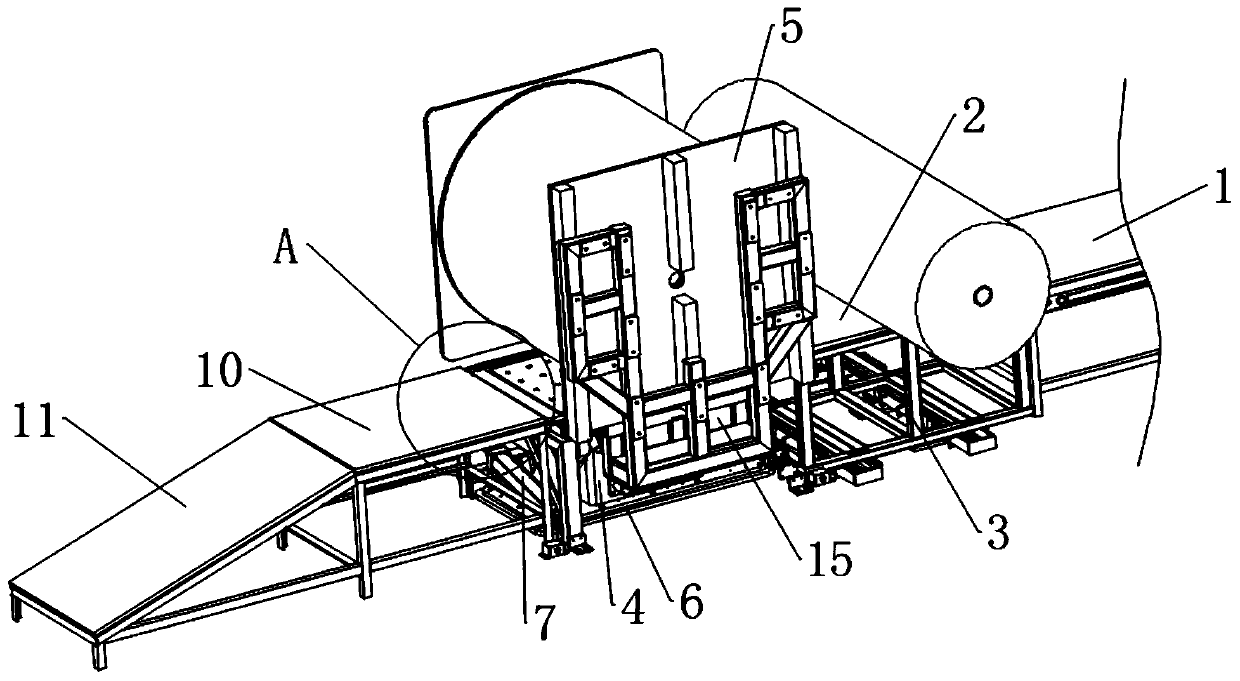

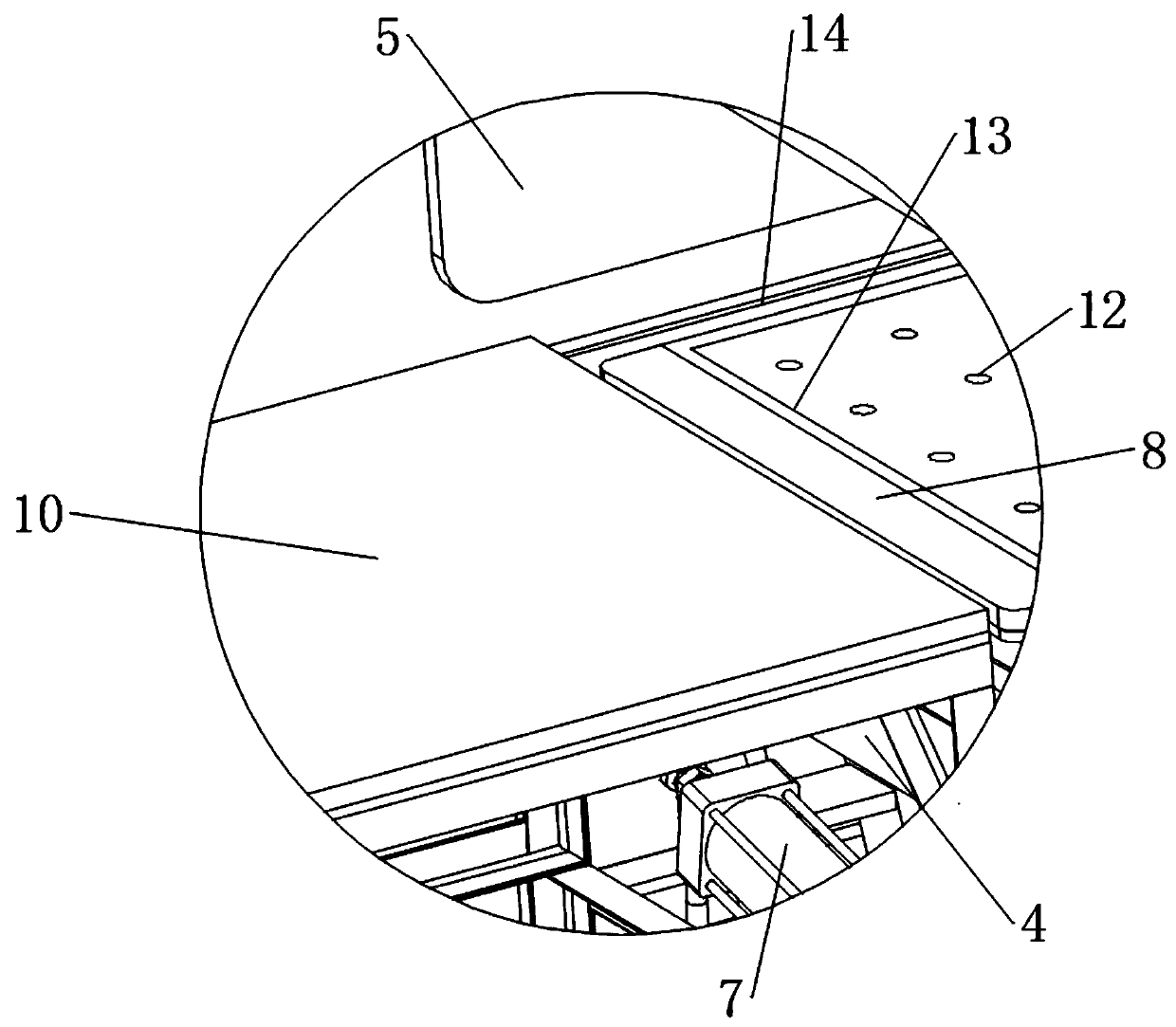

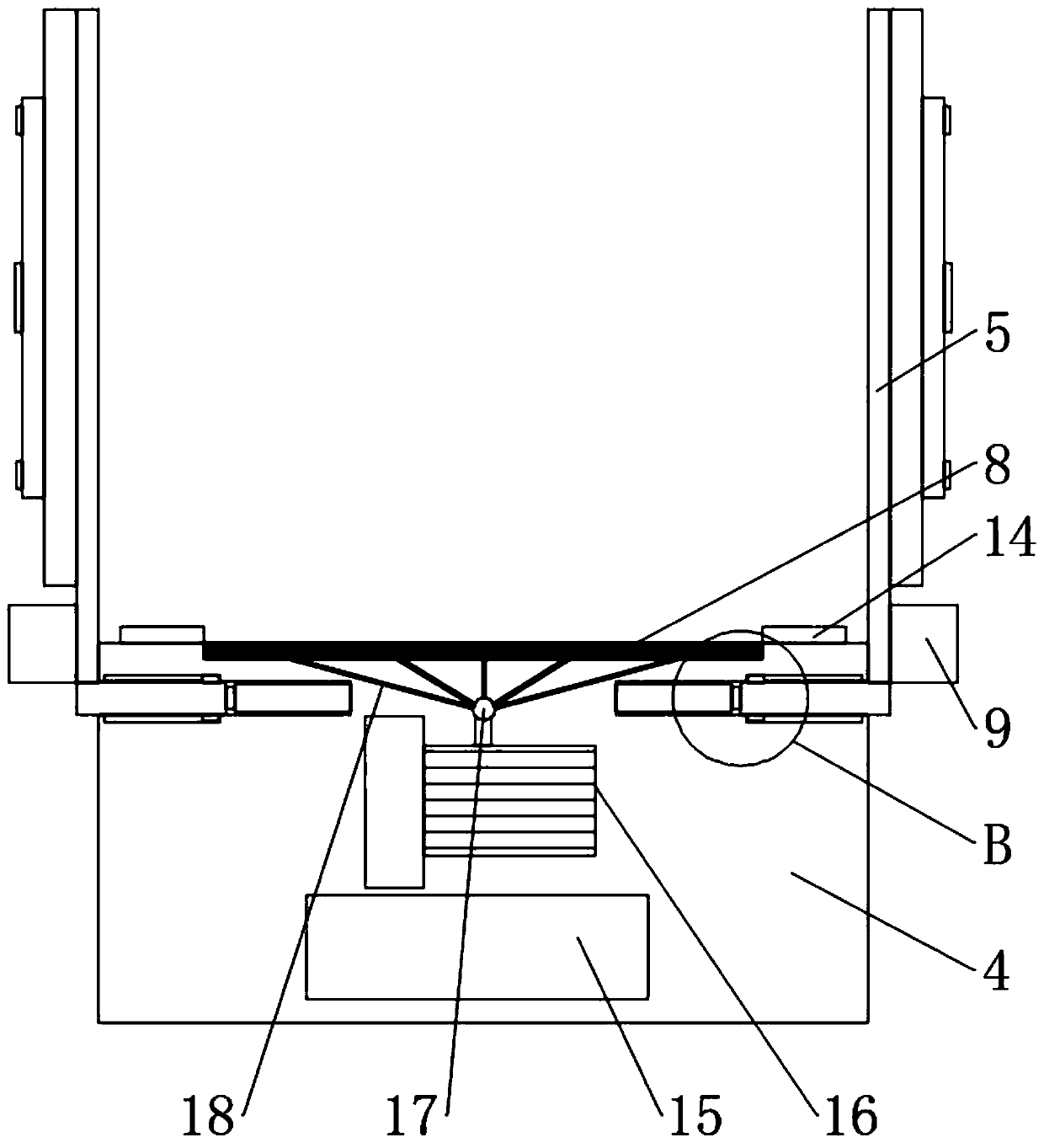

[0042] see figure 1 , a packaging and turning platform for large-diameter synthetic paper film roll products in the film industry, including a transmission platform 1, one end of the transmission platform 1 is connected to a centering platform 2, and the centering platform 2 plays the role of adjusting the centering, and the transmission platform 1 and the centering platform 2 are equipped with conveyor belts, which is the prior art, and will not be repeated. A pair of electric slides 3 is installed on the lower side of the centering platform 2, and the sliding between the centering platform 2 and the pair of electric slides 3 The ends are connected by bolts, and the distance adjustment of the centering platform 2 can be realized through the electric slide table 3, and then the centering of the film coil and the fine-tuning platform 4 can be realized. The side of the centering platform 2 far away from the transmission platform 1 is provided with an overturning platform 6. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com