Flexible micro rail transporter and using method thereof

A technology of transportation device and micro-rail, which is applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of poor passability of trolleys, difficulty in laying out rail trolley tracks, and laborious pulling and delivery of goods, etc., to achieve occupancy The effect of small space, overall light weight, and easy entry and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

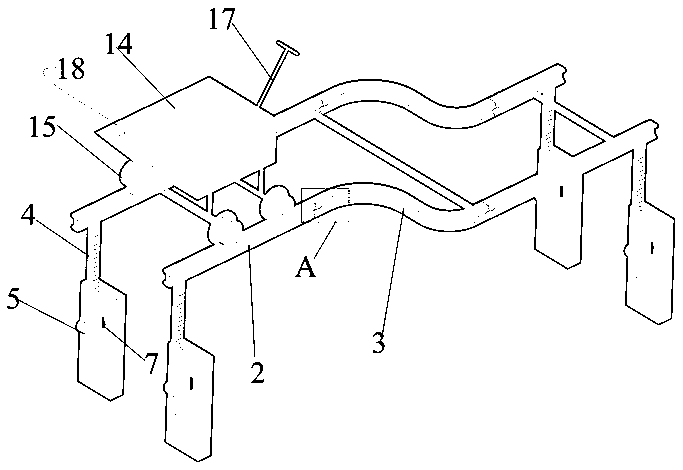

[0041] A flexible micro-rail transportation device, such as figure 1 As shown, it includes a transportation track, an adjustable support supporting the transportation track, and a cargo trolley 18 placed on the transportation track; the transportation track includes two parallel steel tracks, and a first connecting support 1 is provided between the steel tracks. It includes a straight track unit 2 and a curved track unit 3. The adjacent straight track units 2 and the adjacent straight track units 2 and the curved track units 3 are fixed by splicing components, such as image 3 As shown, the splicing component is a tenon-and-mortise structure; the adjustable support includes several height-adjustable support units, the height-adjustable support unit includes a rack 4, a rotating handle 5, a gear 6, a clamp 7 and a sleeve 8, and a rack 4 The top is supported under the transportation track, and the lower part is built into the sleeve 8. One end of the rotating handle 5 is fixed to t...

Embodiment 2

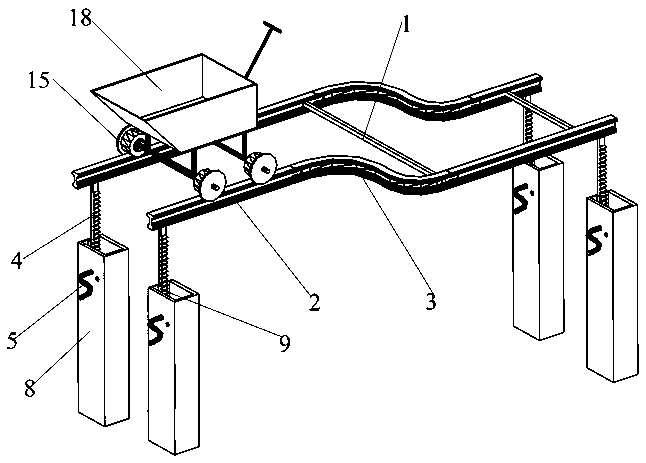

[0043] In the first embodiment, the cross section of the sleeve 8 is square, and the width of the inner wall of the sleeve 8 to which the rack 4 abuts is adapted to the width of the rack 4. The second embodiment is based on the first embodiment. figure 2 It can be seen that the width of the sleeve 8 is greater than the width of the rack 4, the inner wall of the sleeve 8 is provided with baffles 9 on both sides of the rack 4, and the space between the two baffles 9 is the running channel of the rack 4.

Embodiment 3

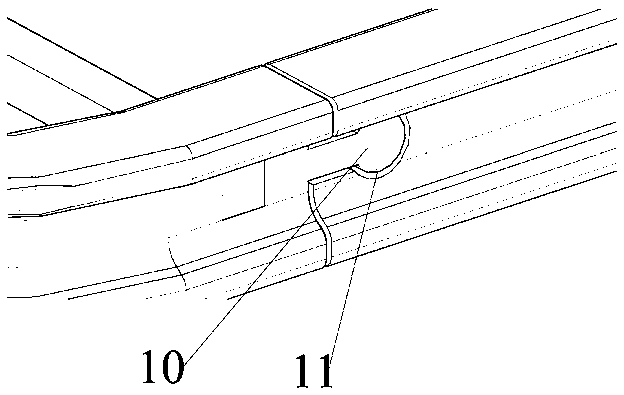

[0045] On the basis of the first embodiment, the tenon-and-mortise structure includes a protrusion 10 and a groove 11 respectively provided on adjacent rail units. The protrusion 10 includes a head and a neck. The shape of the groove 11 is similar to that of the protrusion. The shape of the part 10 is adapted, the cross section of the head is a circular structure, and the diameter of the circular structure is larger than the maximum width of the neck, such as Figure 7~9 As shown, the cross-section of the head is rectangular, trapezoidal, inverted trapezoid and arrow-shaped. The arrow shape is not shown. The width of the neck is the same as the length of the shortest bottom side of the trapezoid or inverted trapezoid. The bottom surface of the steel track is provided with teeth for securing The square steel 16 of the strip 4, for ease of production, the straight track unit 2 and the curved track unit 3 are made of square steel. Each curved track unit 3 includes a curved section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com