A cross-link lifting structure, bed frame and nursing bed

A lifting structure and cross-link technology, applied in the field of nursing beds, can solve problems such as overloading of telescopic elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

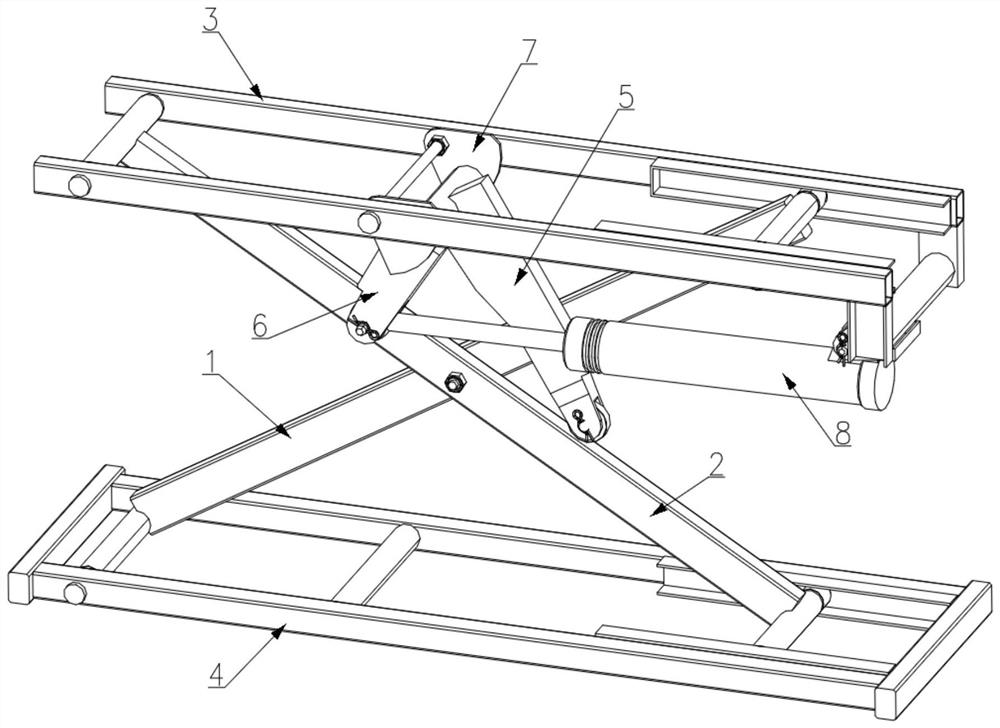

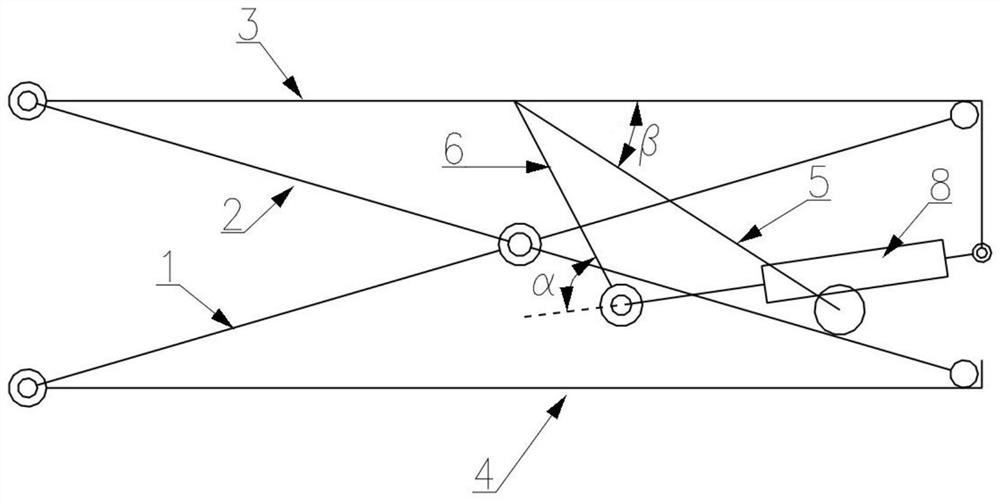

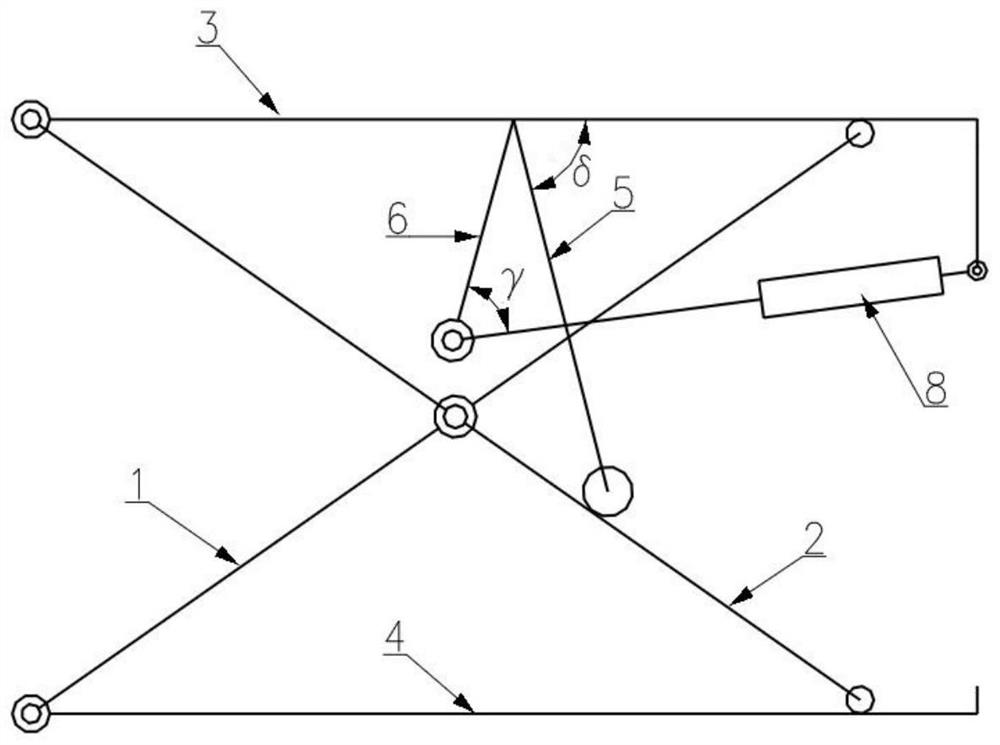

[0058] Such as Figure 1 to 3 As shown in the first embodiment provided by the present invention, the present embodiment provides a cross-link lifting structure. As described in the context, the cross-link lifting structure in the prior art is easy to cause damage to the telescopic element, and the technician usually selects a large thrust of the extensive thrust, but it also causes unnecessary waste of production resources. The crosslink lifting structure provided in this embodiment is well solved the above problems.

[0059] This embodiment includes the first link 1 and the second link 2, the first link 1 and the second link 2 intersect together in Type X; also includes a bracket 3 and a frame 4, a frame 4 On the ground, the bracket 3 is used to support the weight above. Both ends of the bracket 3 are mounted on the upper end of the first link 1 and the second link 2. The upper end of the first link 1 slides on one end of the bracket 3, and the upper end of the second link 2 is h...

Embodiment 2

[0073] Such as Figure 4 As shown, in Example 2, which is provided for the present invention, the present embodiment provides a bed frame. Including the upper frame 9, both ends of the upper frame 9 are respectively mounted, respectively, the cross-link lifting structure described in Embodiment 1, respectively. The bed frame can be rising, lowered, tilted, and other actions under the drive of the cross lifting structure.

[0074] In order to avoid the upper frame 9, he slipped from the bracket 3 during the inclination. In this embodiment, the inclined limit structure 10, such as Figure 5 As shown, the inclined limit structure 10 includes a curved guide rail 11, which is fixed to the upper frame 9, has a curved slide; the roller 12 is fixed to the bracket 3, during the upper frame 9 tilt, The rollers 12 are adapted to slide in the slot of the curved rail 11, and the upper frame 9 is positioned to avoid the sliding of the upper frame 9.

[0075] The present embodiment is due to the...

Embodiment 3

[0077] This embodiment provides a care bed, including a bed, and the bed plate is laid in the upper surface of the upper frame 9 in Example 2. The present embodiment is due to the installation of the crosslink lifting structure described in Embodiment 1, thereby also has all the advantages of the crosslink lifting structure in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com