Emulsified waste liquid processing device capable of recovering resources

A technology for waste liquid treatment and resource recovery, applied in filtration treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. efficiency, improve uniformity, and achieve the effect of resource recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

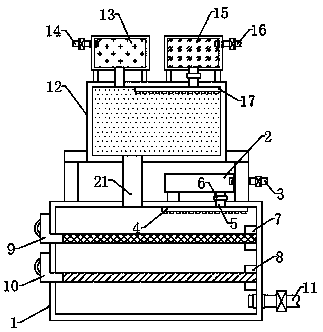

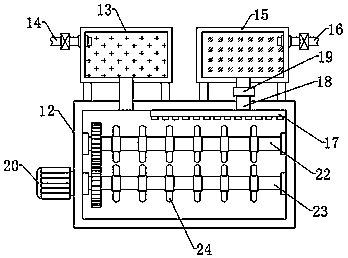

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

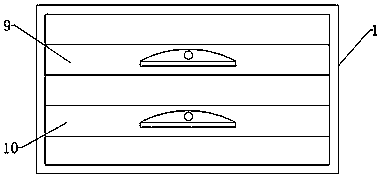

[0023] Such as Figure 1-3 As shown, the present invention provides a technical solution: an emulsified waste liquid treatment device that can recover resources, including:

[0024] Purification unit 1, the purification unit 1 has a rectangular structure as a whole, the upper surface side of the purification unit 1 is equipped with a first drug delivery unit 2 through a bracket, and one end surface of the first drug delivery unit 2 penetrates and locks A first medicine feeding pipe 3 is installed, and a first spray pipe 4 is installed on one side of the inside of the purification part 1, and a first spray pipe 4 is installed between the first medicine delivery part 2 and the first spray pipe 4 in the purification part 1. The first drug delivery tube 5, and the first flow mete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com