Waste paper pulping fine screening tailing treatment technology

A technology for processing and fine-screening tailings, applied in fiber raw material processing, textile and papermaking, etc., can solve the problems of waste of resources, low efficiency, large amount of waste paper pulping and slag discharge, etc., to ensure the purification effect and bonding strength. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

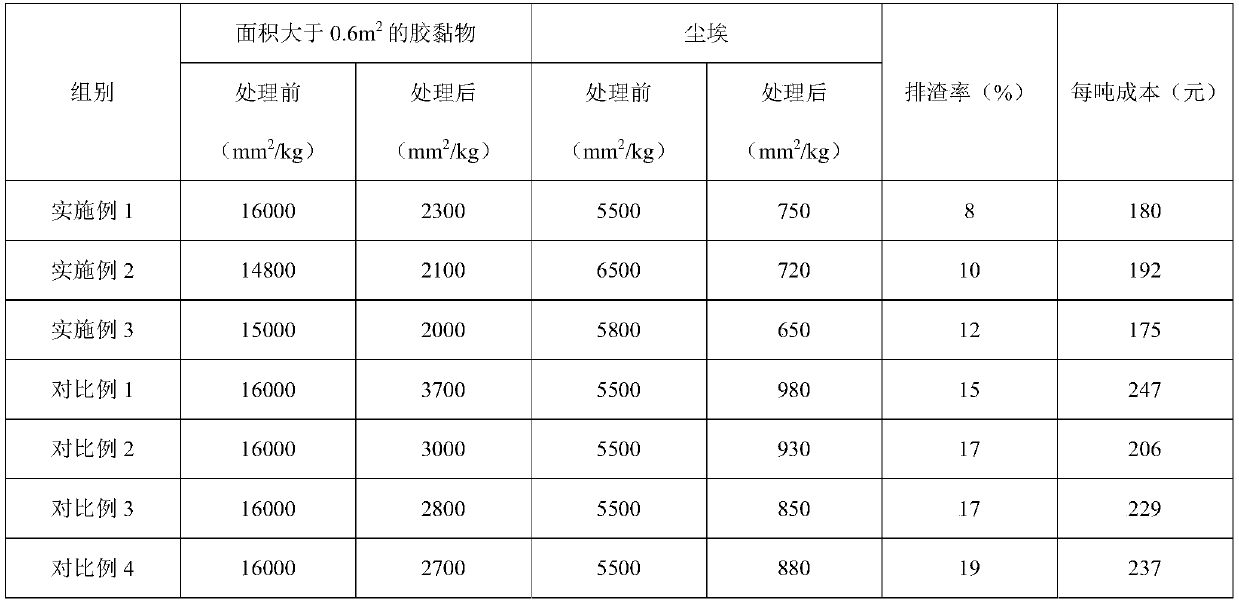

Examples

Embodiment 1

[0040] (1) Send the waste paper pulping tailings into the transition tank 1, adjust the concentration to 1%, and then pass through a section of fine sieve with a pressure screen with a sieve gap of 0.1mm to obtain a section of good pulp and a section of tailings, and a section of good pulp enters the removal The slag remover is further screened and purified, the pulp concentration of the slag remover is 0.8%, and the pulp feed pressure is 200kPa;

[0041] (2) One section of fine pulp passes through the medium concentration standpipe 1, wherein the incoming pulp concentration is 2%, and the outgoing pulp concentration is 0.8%, and one section of tailing pulp is sent to the second stage fine screen with a sieve gap of 0.1mm to obtain the second stage of fine pulp and Second stage tail slurry;

[0042] (3) The second-stage good pulp is returned to the first-stage fine screen for further processing; the second-stage tailing pulp is sent to the last stage fine screen with a sieve g...

Embodiment 2

[0046] (1) Send the waste paper pulping tailings into the transition tank 1, adjust the concentration to 3%, and then pass through a section of fine sieve with a pressure screen with a sieve gap of 0.15mm to obtain a section of good pulp and a section of tailings, and a section of good pulp enters the removal The slag remover is further screened and purified with a pulp concentration of 1.2% and a pulp feed pressure of 350kPa;

[0047] (2) One section of good pulp passes through the medium concentration standpipe 1, wherein the incoming pulp concentration is 4%, and the outgoing pulp concentration is 1.2%, and one section of tailing pulp is sent to the second stage fine screen with a sieve gap of 0.15 mm to obtain the second stage good pulp and Second stage tail slurry;

[0048] (3) The second-stage good pulp is returned to the first-stage fine screen for further processing; the second-stage tailing pulp is sent to the final stage fine screen with a sieve gap of 0.2 mm to obta...

Embodiment 3

[0052] (1) Send the waste paper pulping tailings into the transition tank 1, adjust the concentration to 1%, and then pass through a section of fine sieve with a pressure screen with a sieve gap of 0.1mm to obtain a section of good pulp and a section of tailings, and a section of good pulp enters the removal The slag remover is further screened and purified with a pulp concentration of 1% and a pulp feed pressure of 300kPa;

[0053] (2) One section of fine pulp passes through the medium concentration standpipe 1, wherein the incoming pulp concentration is 3%, and the outgoing pulp concentration is 0.81%, and one section of tailing pulp is sent to the second stage fine screen with a sieve gap of 0.15 mm to obtain the second stage of good pulp and Second stage tail slurry;

[0054] (3) The second-stage good pulp returns to the first-stage fine screen for further processing; the second-stage tailing pulp is sent to the final stage fine screen with a sieve gap of 0.25mm to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com