Hobbing cutter on reverse circulation drilling machine for breaking extremely-hard rock

A reverse circulation, rock technology, applied in the direction of drill bits, drilling equipment, earthwork drilling and mining, etc., can solve the problems of low rock breaking efficiency, unfavorable crack closure, easy wear of the cutter shell, etc., and achieve the effect of improving rock breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

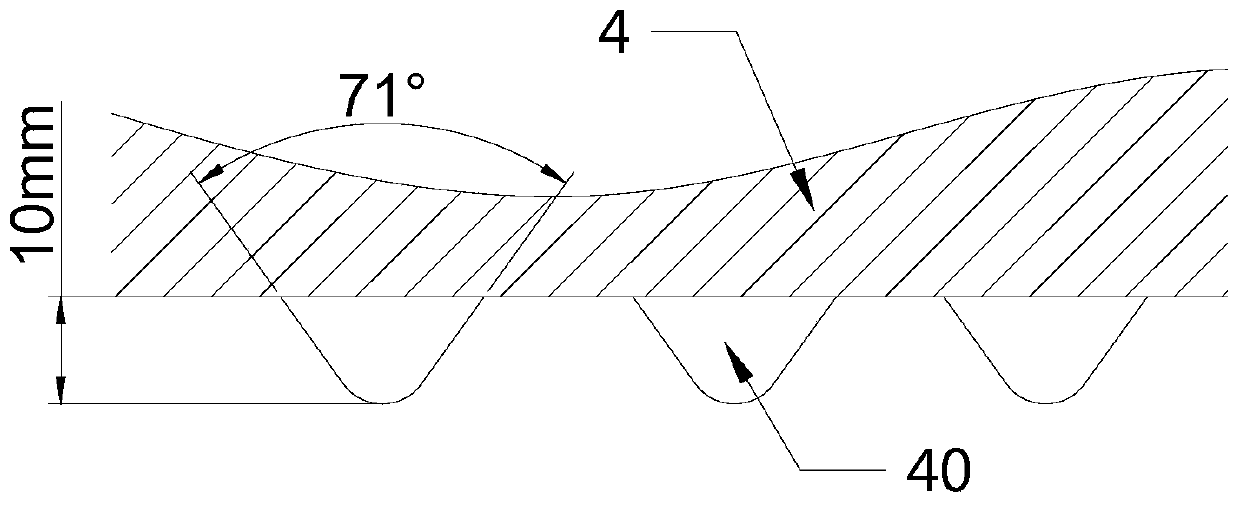

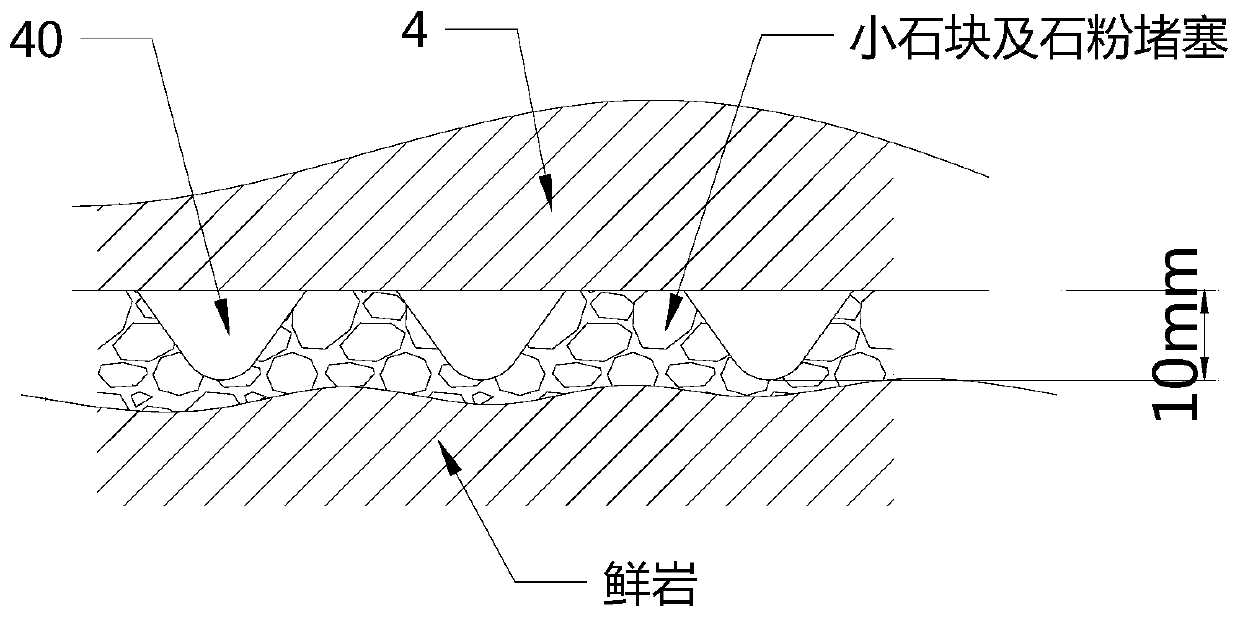

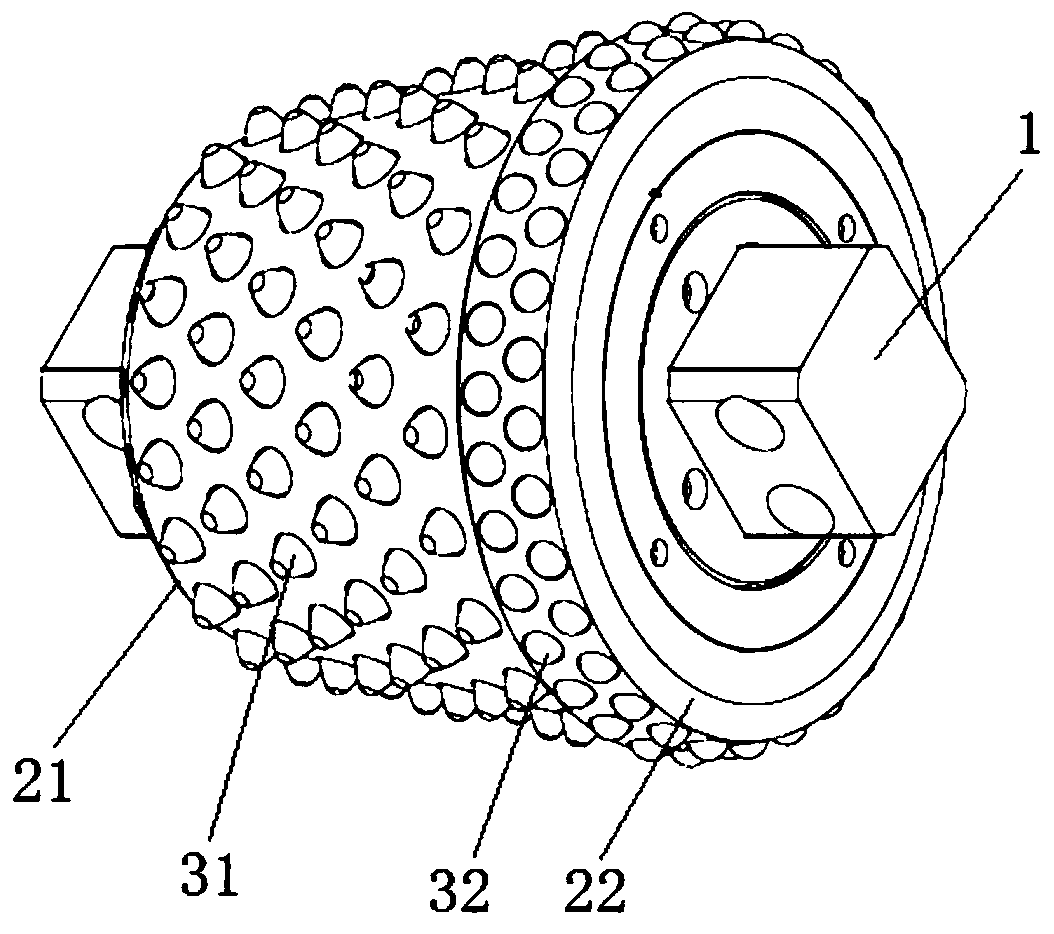

[0024] see Figure 3 to Figure 6 , the hob of the reverse circulation drilling rig used for breaking extremely hard rocks of the present invention includes a main shaft 1, a cutter housing sleeved on the main shaft 1 and rock-breaking teeth installed on the outer surface of the cutter housing.

[0025] The main shaft 1 comprises a circular shaft positioned in the inner chamber of the cutter housing and two sections of square shafts respectively located at the two ends of the circular shaft and protruding from the two end faces of the cutter housing; the middle part of the circular shaft is provided with a flange, and the main side of the flange and A thrust bearing 11 and axle sleeves 12, 13 are respectively arranged in turn on the back side, and a circle of rollers 14, 15 is arranged in each axle sleeve 12, 13, and the outer ends of the two axle sleeves 12, 13 and the roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com