Novel oil field oil extraction and pumping machine device and operating method

A pumping unit and oilfield technology, which is applied in the direction of production fluid, earthwork drilling, wellbore/well parts, etc., can solve the problems of inconvenient fracture welding, easy fracture, thin thickness, etc., and achieve firm fixation, loading and Easy to remove and fast results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

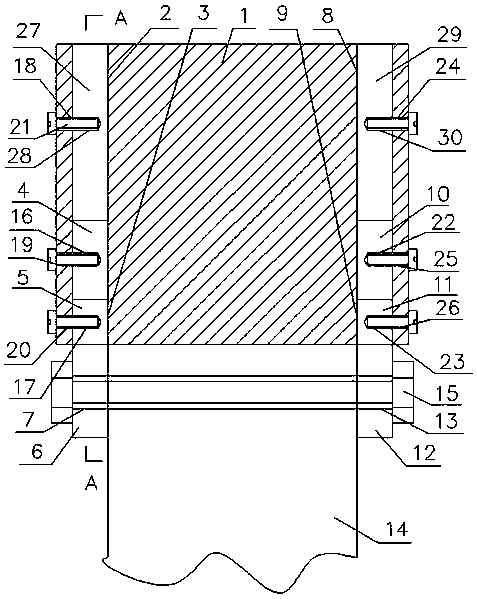

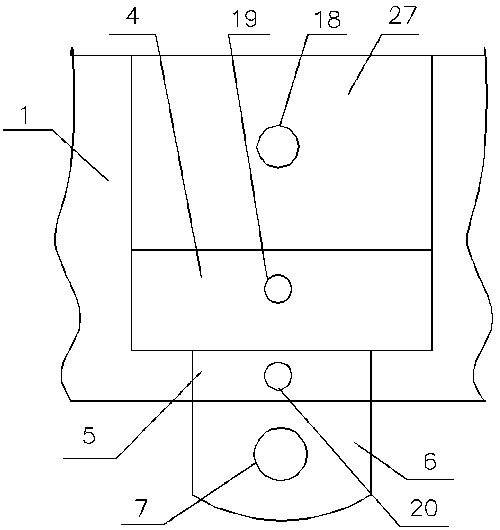

[0018] A novel oil field oil production pumping unit, its composition comprises: beam 1, described beam has front slot 2 and front fixing slot 3, and described front fixing slot is positioned at the below of described front slot , the length of the front fixing slot is less than the length of the front slot, the front fixing slot is located in the middle of the front slot, the front slot is inserted into the front board 4, the The front board is fixedly connected to the front fixing plate 5, the bottom of the front fixing board is fixedly connected to the front splint 6, the front splint has a front clamping hole 7, and the front splint is located at the bottom of the beam, The front fixing plate is inserted into the front fixing groove; the beam has a rear slot 8 and a rear fixing groove 9, and the rear fixing groove is located below the rear slot, and the The length of the rear fixing slot is less than the length of the rear slot, the rear fixing slot is located in the middl...

Embodiment 2

[0021] In the novel oil production pumping unit described in Embodiment 1, the front inserting plate, the front fixing plate, and the front splint are integrally structured, and the front inserting plate is provided with a front middle fixing hole 16 , the front fixing plate has a front bottom fixing hole 17, and the front of the described beam has a front top concentric fixing hole 18, a front middle concentric fixing hole 19, and a front bottom concentric fixing hole 20 in sequence. The front center fixing hole coincides with the front center concentric fixing hole and is fixed by connecting screws 21; the front bottom fixing hole coincides with the front bottom concentric fixing hole and is connected by screws; the rear board 1. The rear fixing plate and the rear splint are integrally structured, the rear mounting plate has a rear middle fixing hole 22, the rear fixing plate has a rear bottom fixing hole 23, and the traveling beam There are rear top concentric fixing holes ...

Embodiment 3

[0024] In the novel oil production pumping unit described in Embodiment 2, the front closing plate 27 is inserted into the front slot, the bottom of the front closing plate contacts the front inserting plate, and the front closing plate opens. There is a front top fixing hole 28, the front top fixing hole coincides with the front top concentric fixing hole, and is fixed by connecting screws; the rear closing plate 29 is inserted in the described rear slot, and the rear closing plate of the described back closing plate The bottom contacts the rear board, and the rear closure plate has a rear top fixing hole 30, and the rear top fixing hole coincides with the rear top concentric fixing hole and is fixed by connecting screws; the front The closing plate blocks the front slot, and the rear closing plate blocks the rear slot.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap