Pipeline structure damage monitoring system based on wireless sensor network

A wireless sensor and damage monitoring technology, applied in the field of pipeline structure damage monitoring system, can solve the problems of troublesome wiring, poor real-time performance, complicated operation, etc., and achieve the effect of solving difficult wiring, low power consumption, and long communication distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

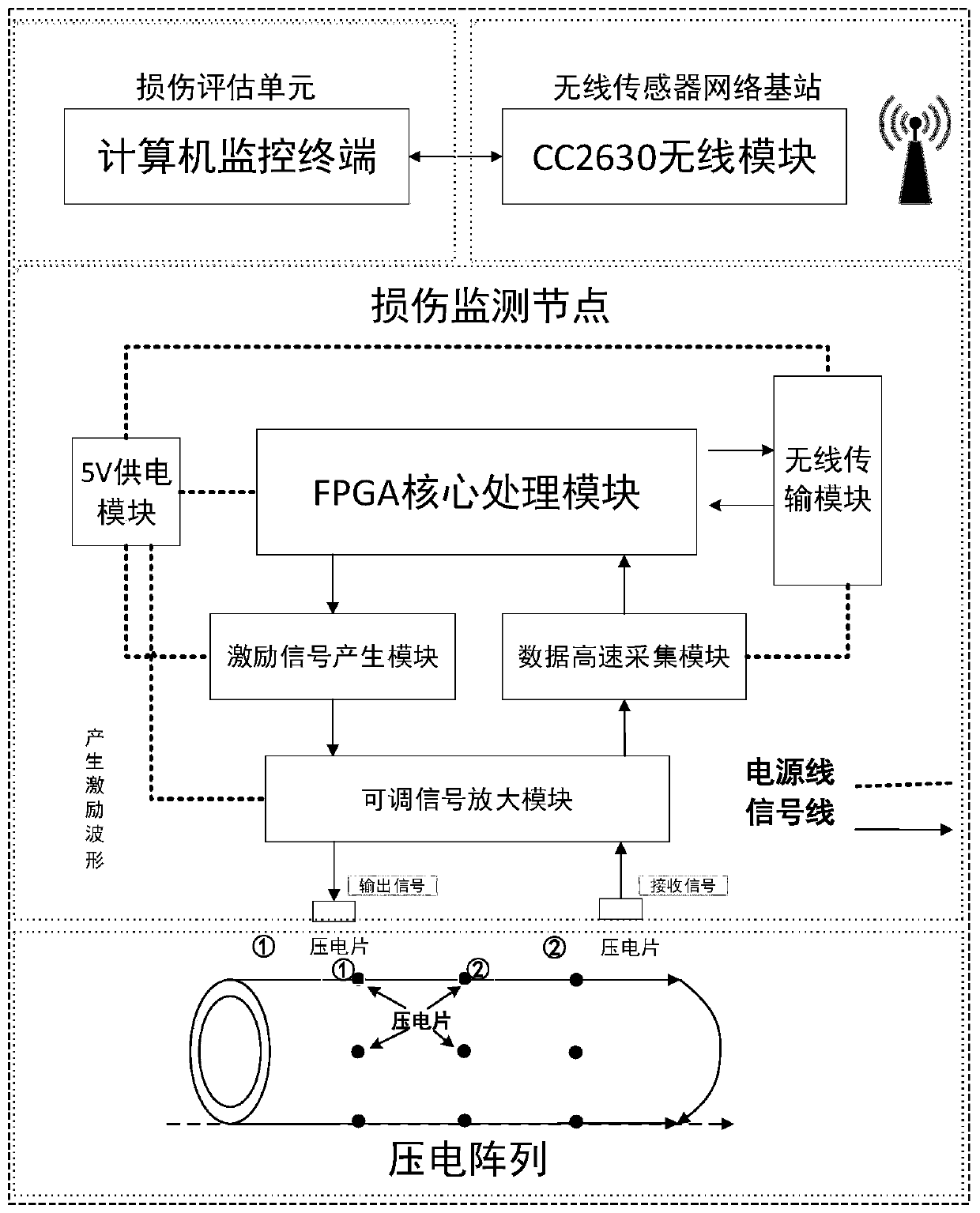

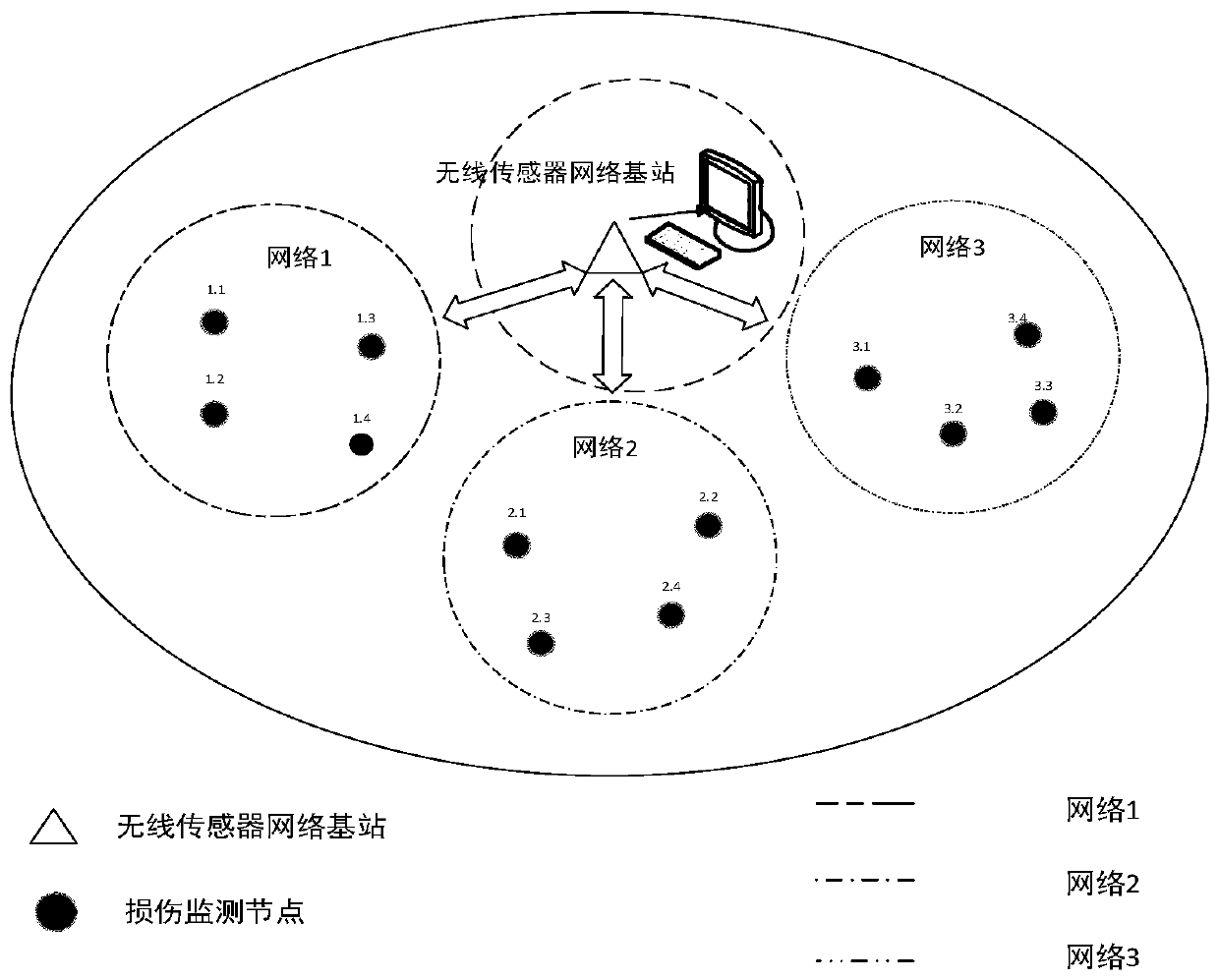

[0019] Such as figure 1 As shown, a pipeline structure damage monitoring system based on wireless sensor network, including: piezoelectric array, several damage monitoring nodes, wireless sensor network base station and damage assessment unit. The damage monitoring node includes an FPGA core processing module, an excitation signal generation module, a high-speed data acquisition module, an adjustable signal amplification module, a wireless transmission module and a power supply module, and the damage monitoring node generates an excitation signal through the excitation signal generation module to act on the piezoelectric array , so that it generates high-frequency ultrasonic guided waves on the inner wall of the pipeline. When the high-frequency ultrasonic guided wave encounters a pipeline defect, a part of the high-frequency ultrasonic guided wave will reflect and rebound. The piezoelectric array is also used to receive the echo reflected back when the pipeline is damaged. Si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com