Improved low-voltage ride-through control system

A low-voltage ride-through and control system technology, applied in control systems, vector control systems, control generators, etc., can solve problems such as increasing the operating frequency range of fans and enhancing the robustness of fan operating systems, so as to increase the operating frequency range , solve the problem of low-voltage ride-through, and improve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

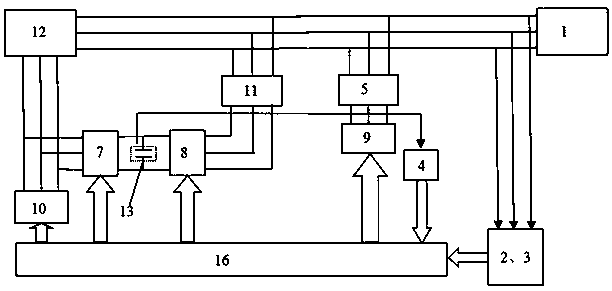

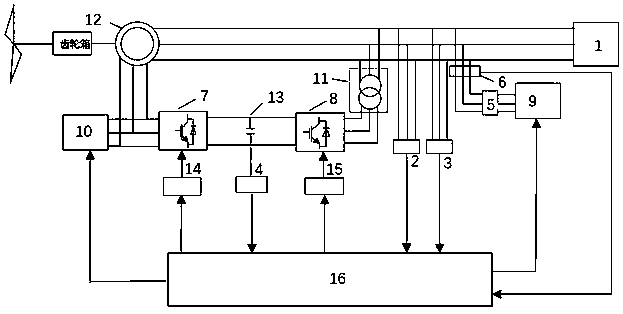

[0053] An improved low-voltage ride-through control system, such as figure 1 As shown, it includes a three-phase grid 1, a reactor 5, a rotor-side converter 7, a grid-side converter 8, a TSC circuit 9, a grid-side transformer 11, a doubly-fed induction motor 12, a DC capacitor 13 and a main control module 16; The TSC circuit 9 is a thyristor switching capacitor circuit, the three-phase power grid 1 is respectively connected with the reactor 5, the grid-side transformer 11, the doubly-fed induction motor 12 and the detection module, and the reactor 5 is sequentially connected with the TSC circuit 9 and the mains. The control module 16 is connected, the DC capacitor 13 is connected with the detection module, the output end of the main control module 16 is connected with the rotor-side converter 7, the grid-side converter 8 and the active crowbar protection circuit 10 respectively, the rotor The side converter 7 is respectively connected to the doubly fed induction motor 12 and t...

specific Embodiment approach 2

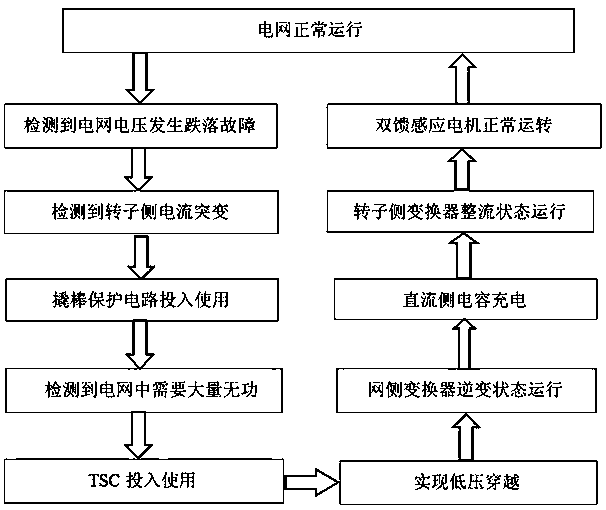

[0061] An improved low-voltage ride-through control system, a low-voltage ride-through reactive power compensation method, and a novel flux linkage observer control for a rotor-side converter based on the improved low-voltage ride-through control system described in the first technical solution, comprising the following steps:

[0062] Step a1, the three-phase power grid is energized, and the three-phase power grid operates normally;

[0063] Step a2, judging in real time whether the voltage of the three-phase power grid has a sag fault, if so, go to step a3;

[0064] Step a3: Collect the current and voltage of the three-phase power grid when the fault occurs through the detection module; detect whether the stator current of the doubly-fed induction motor increases sharply;

[0065] In step a4, the voltage and current collected during the fault are sent to the main control module, and the active crowbar protection circuit is connected to cut off the side of the rotor converter...

specific Embodiment approach 3

[0070] A novel flux linkage observer control method based on the second step a6 of the specific embodiment, such as Figure 4 to Figure 6 shown, including the following steps:

[0071] Step b1, according to the working principle of the doubly-fed induction motor (12), the basic equation of the voltage flux linkage of the rotor and the stator is obtained, as follows:

[0072]

[0073] Step b2, the rotor flux linkage calculation expression based on the voltage model in the two-phase stationary coordinate system (α, β axis system):

[0074]

[0075] After the rotor flux linkage is oriented, the rotor flux linkage can directly pass through the stator current. The d-axis current in the rotor flux linkage coordinate system is:

[0076]

[0077] Step b3, obtain the rotor flux linkage ψ through the current model αβr-i , the rotor flux linkage ψ is obtained through the voltage model αβr-u , ψ αβr-i Low pass filtering with ψ αβr-u After high-pass filtering, the superpositi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com